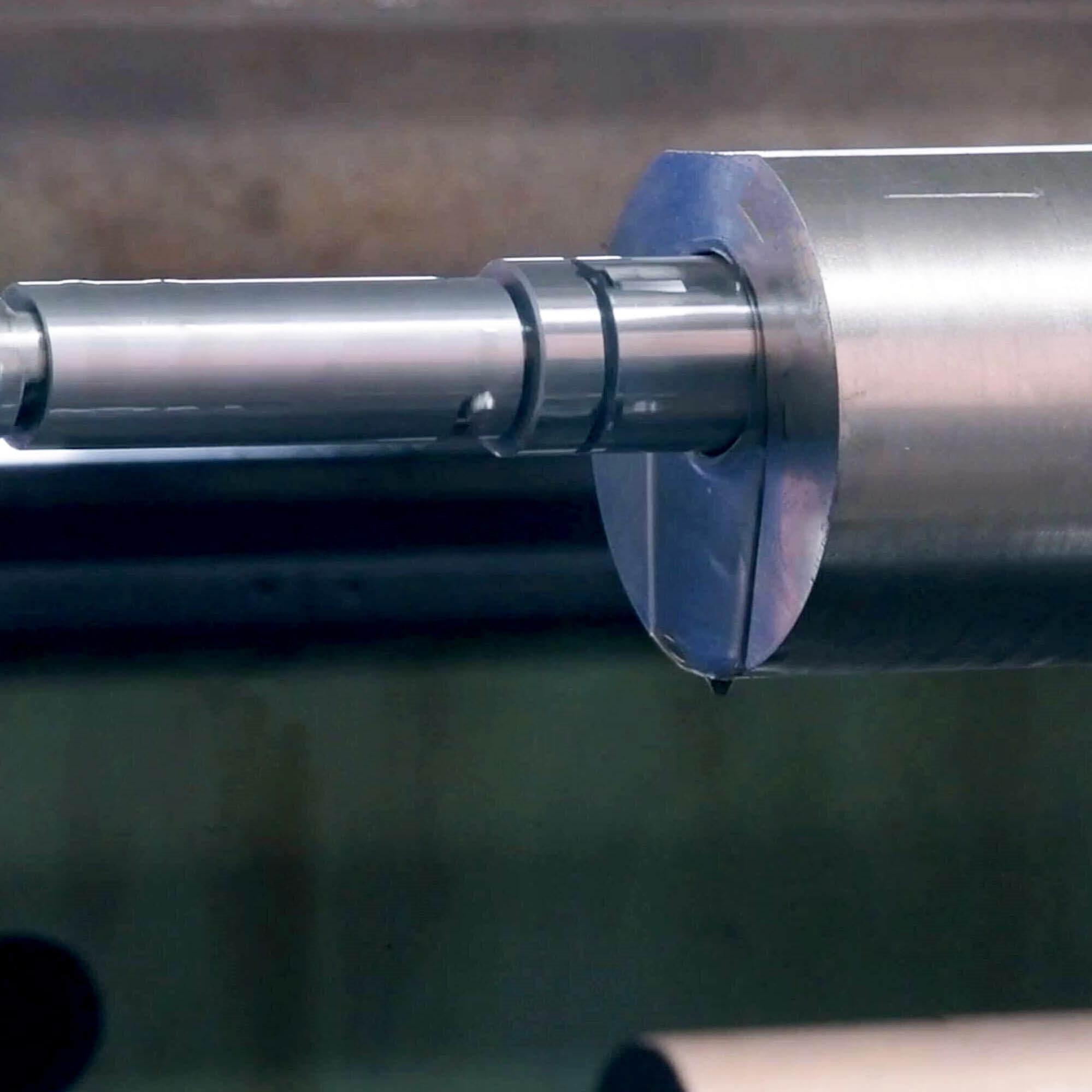

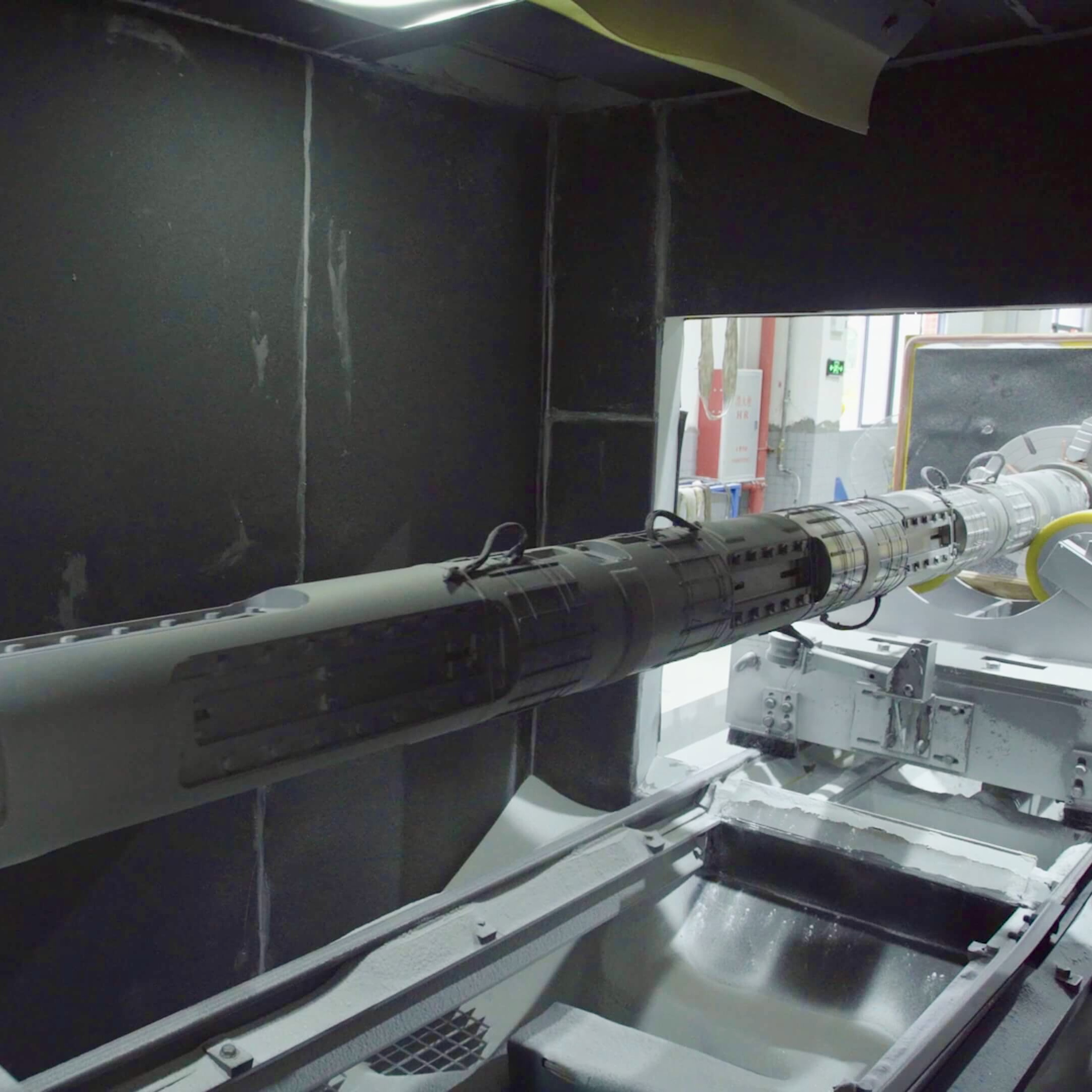

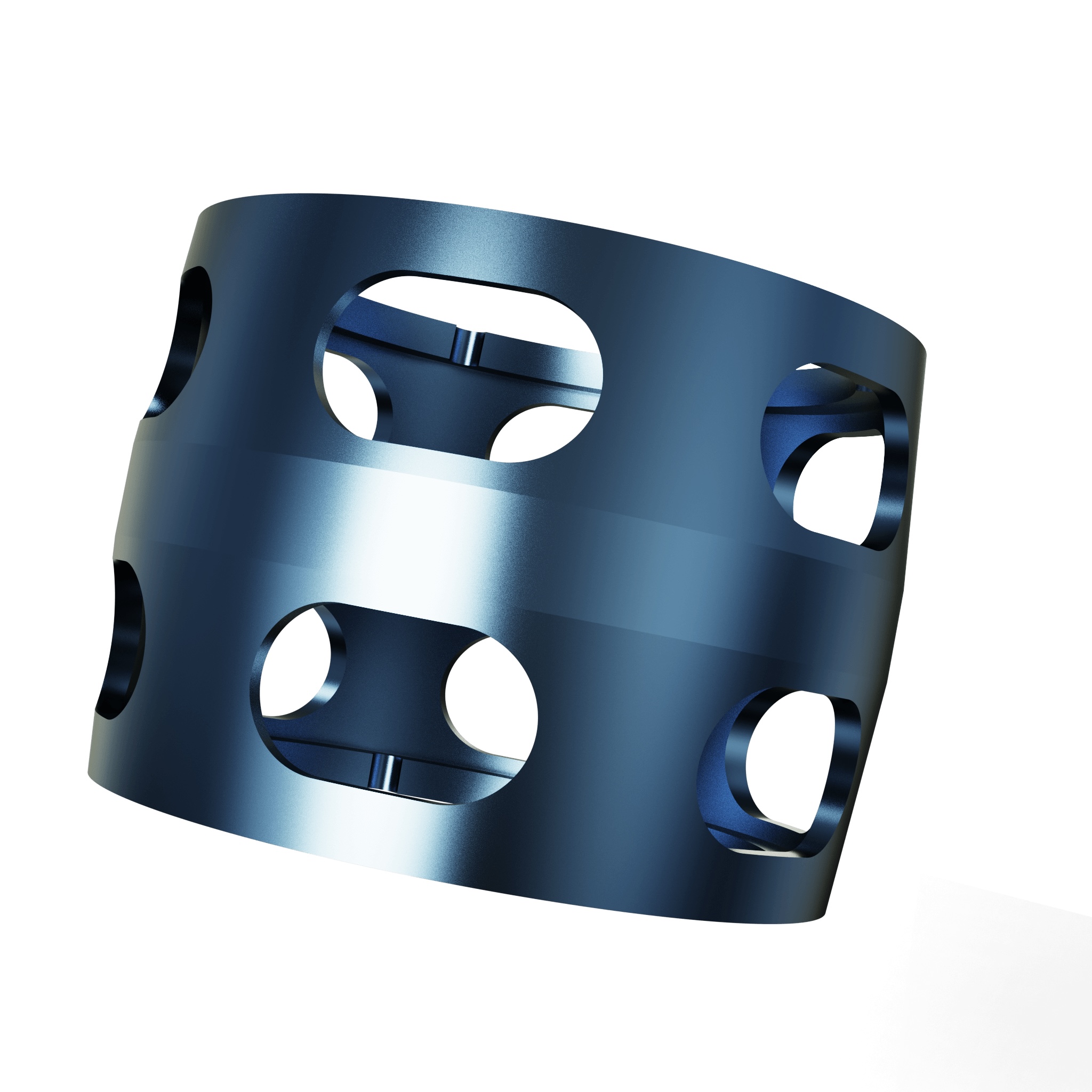

Drilling Resistivity Drill Collars

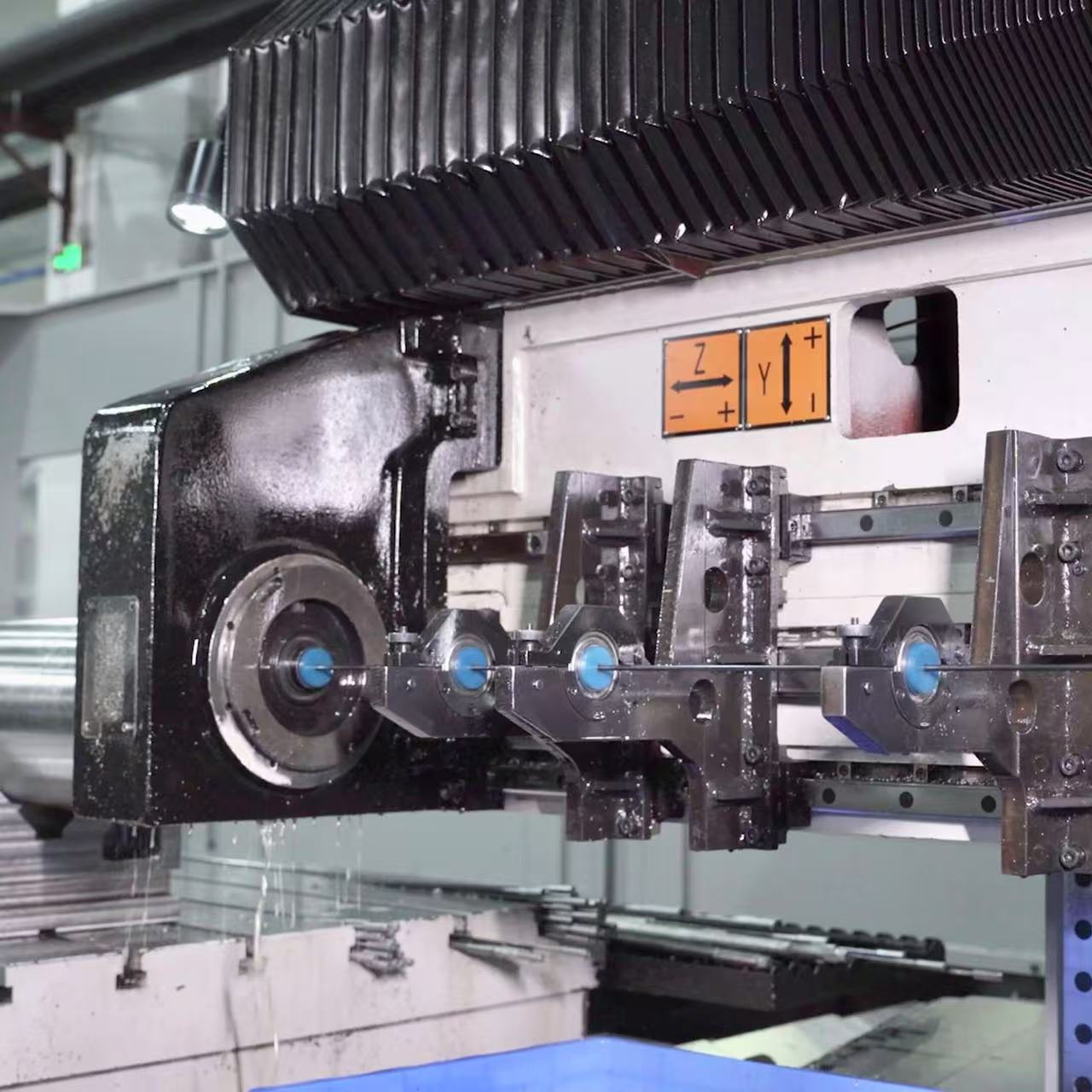

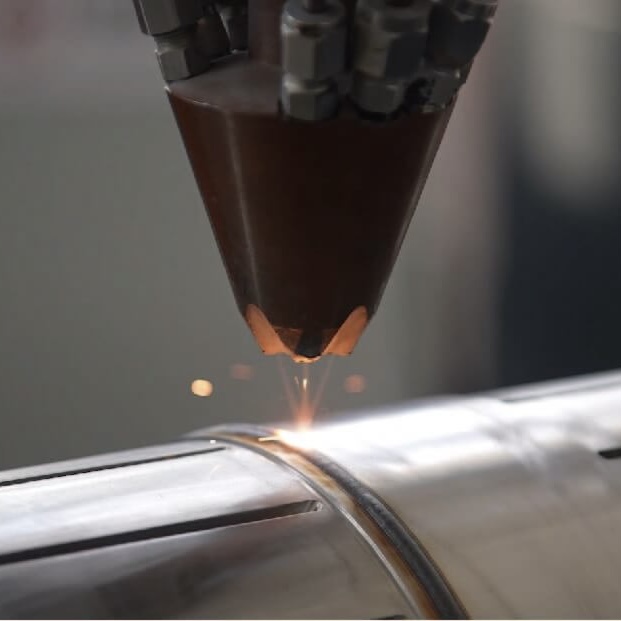

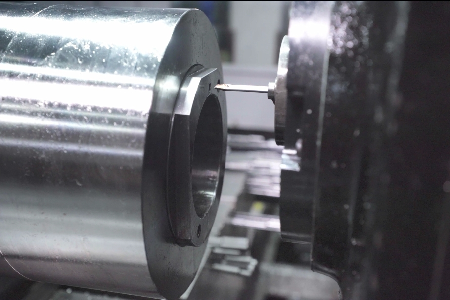

Gun drilling, as a critical deep-hole machining technology, plays an irreplaceable role in high-end manufacturing sectors including aerospace, energy equipment, and precision hydraulics. The client required our independent breakthrough in gun drilling technology to achieve high-precision machining of ultra-large aspect ratio micro-deep holes.

Core Challenges

Core Challenges 1

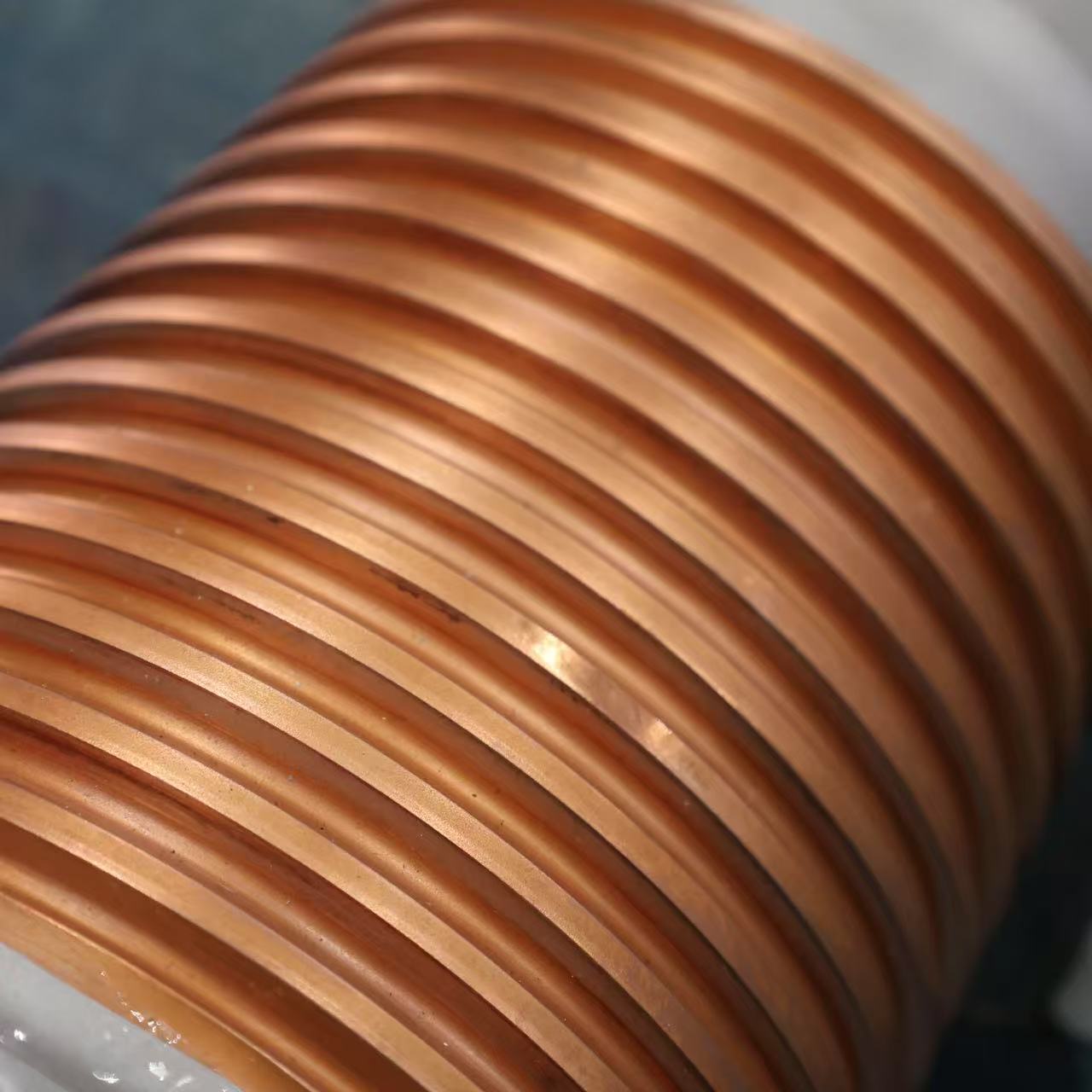

Extreme material properties: using special heat-resistant alloy 15-15HS Max, surface hardness 40-42HRC, belongs to the typical difficult-to-machine materials;

Core Challenges 2

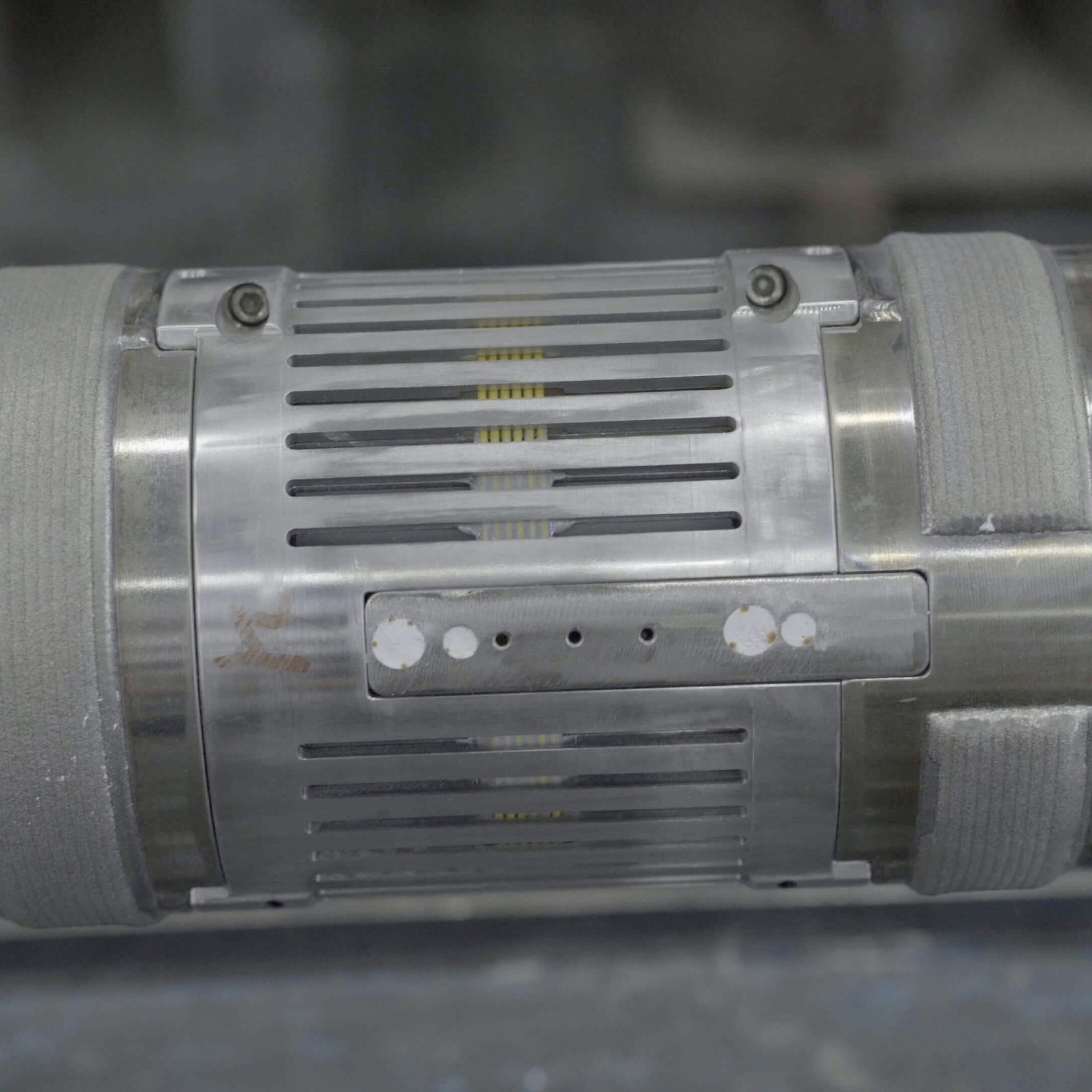

Ultra-large depth-to-diameter ratio machining: in Ф203 × 4162mm slender parts to be machined:

1.Ultra-deep micro-holes: 1-Ф5 × 1821, 1-Ф5 × 3850, 1-Ф5 × 4162, 2-Ф6 × 2680, depth to diameter ratio ≥ 630;

2. Space oblique holes: 1-Ф6×2030 (oblique holes) and 6 groups of radially difficult to process oblique holes;

Core Challenges 3

Rigorous precision requirements: drilling offset ≤ 1mm, hole positioning accuracy ≤ 0.03mm.

Technological Breakthroughs

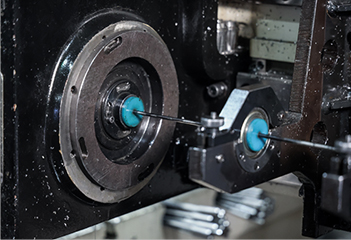

Through independent R&D of customized CNC gun drilling equipment, pecialized guide tooling, and deviation-correction measurement technology, we achieved:

1.Ultra-large depth-to-diameter ratio deep small hole machining (depth-to-diameter ratio ≥630);

2.High-precision angle control capability (0.8mm/100mm);

3.Drilling straightness (<1mm/1000mm);

This technology has reached internationally advanced levels overall.

Applications

1. Standardization: Led the formulation of group standard T/GDMES 0001.3-2024 "CNC Micro-Deep Hole Machining Equipment - Part 3: Ultra-Large Aspect Ratio Hole Machining Equipment";

2. Industrialization and Application: Successfully applied in core components of rotary steerable and LWD systems, achieving breakthroughs across the entire chain of process-equipment-inspection;

3. Patent Layout: Formed multiple invention patents covering machine tool design, process control, and inspection methods, solidifying our position as a core supplier in high-end deep-hole machining.