-

Home

- Technology

- Precision manufacturing process

- Spatial Inclined Hole Processing

Industry challenges

Creating a new benchmark for precision manufacturing with exquisite

craftsmanship and innovative technology

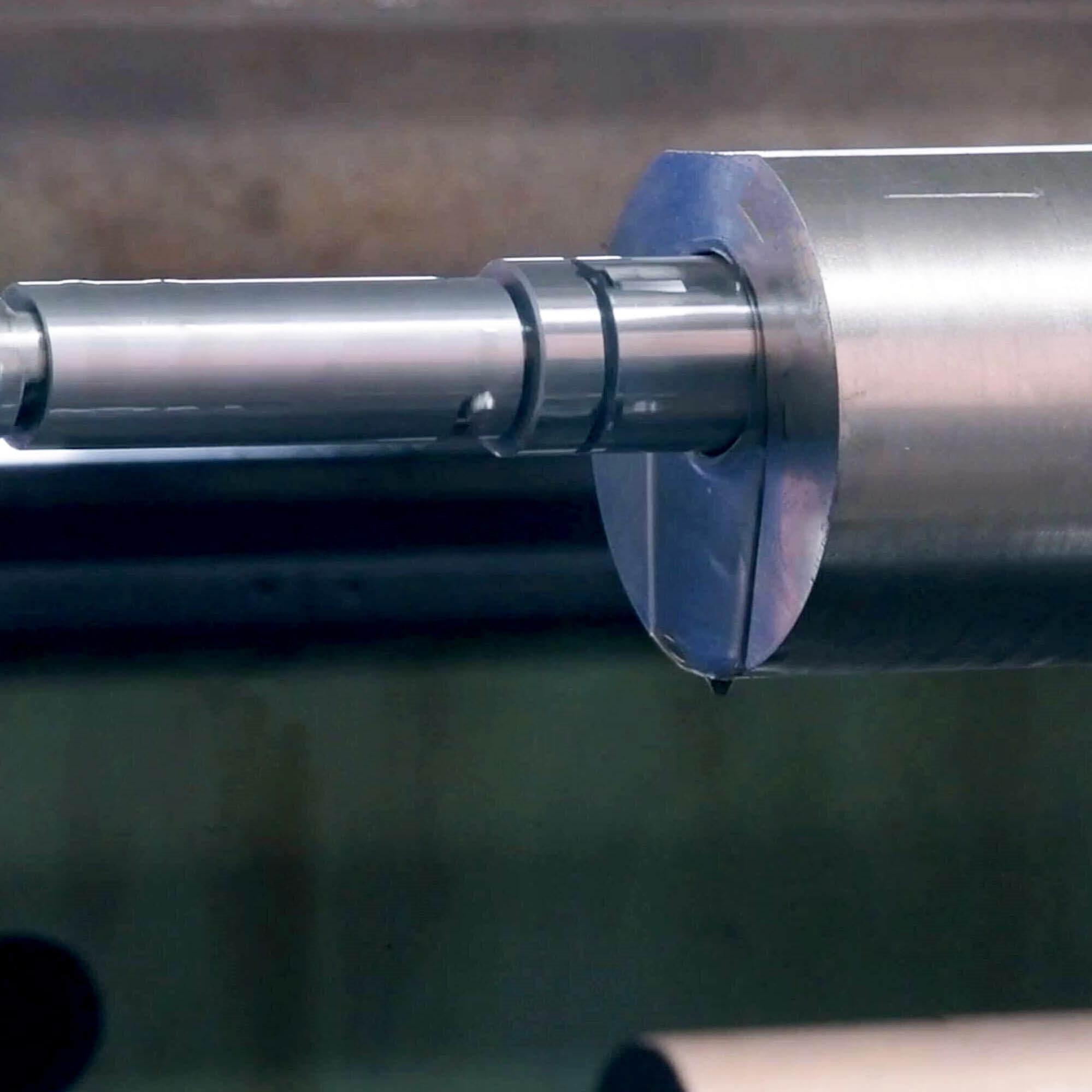

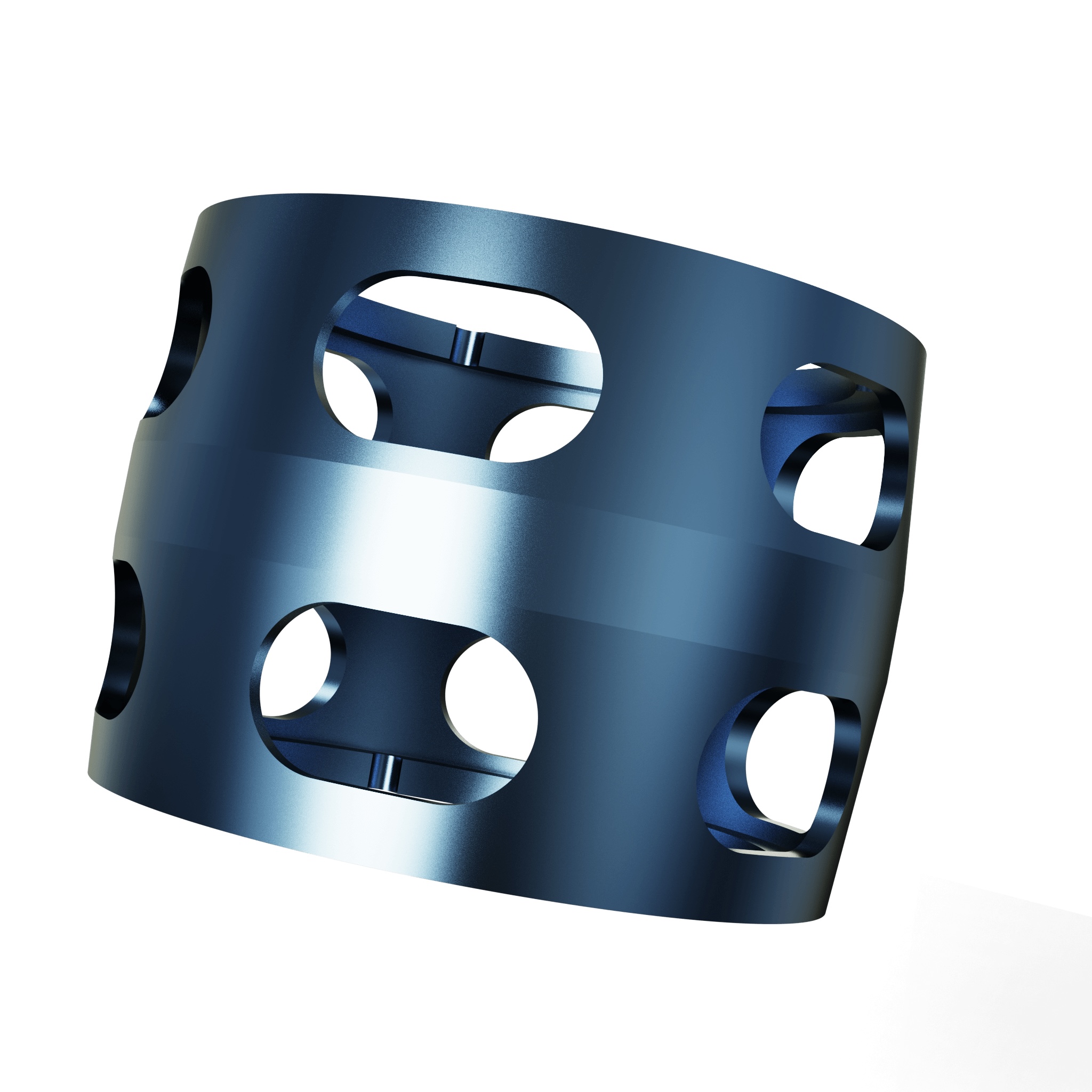

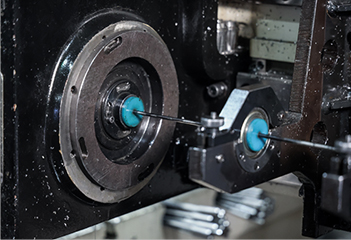

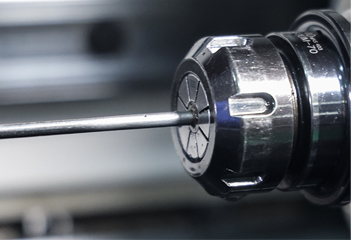

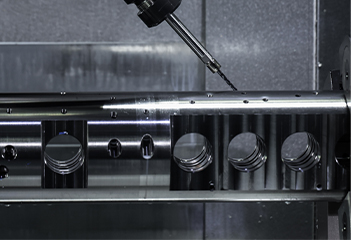

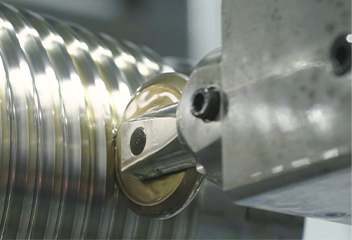

Spatial Inclined Hole Processing

A spatial inclined hole refers to the axis of the hole and the axis of the part are at a certain angle in space. The processing of spatial inclined holes has the following difficulties:

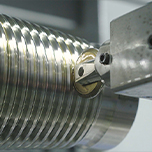

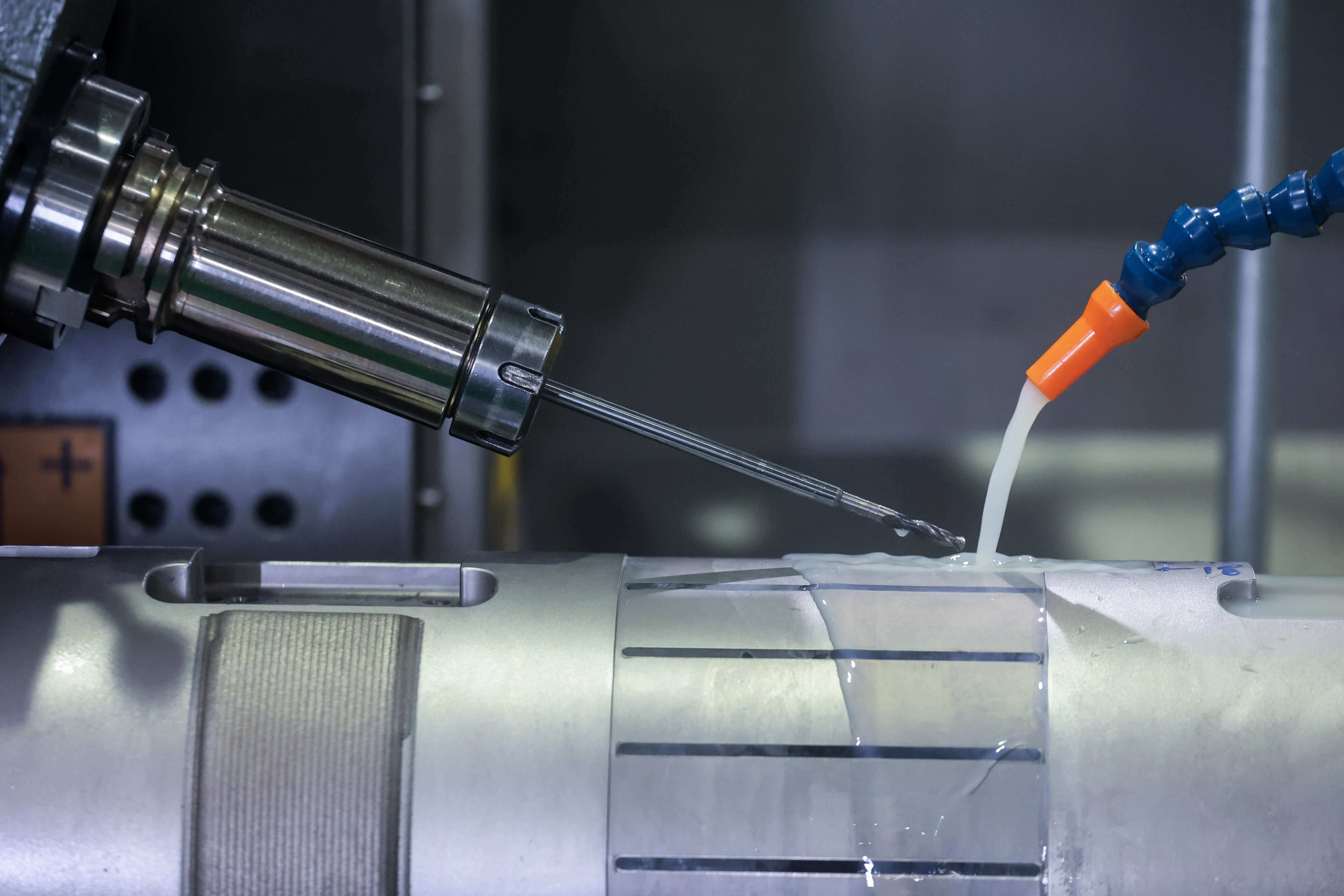

(1) The drill bit is subjected to force on one side when it contacts the workpiece, and the force on the cutting edge of the drill bit pushes the drill bit to one side, causing the drill bit to deflect, slide, etc., and thus be unable to enter the workpiece.

(2) The position of the drill hole can easily deviate from the required position of the workpiece, and the hole drilled on the workpiece cannot meet the specified requirements.

(3) The hole entry will be damaged, destroying the flatness of the hole end face.

(4) During the drilling process, the drill bit is prone to chipping or breaking.

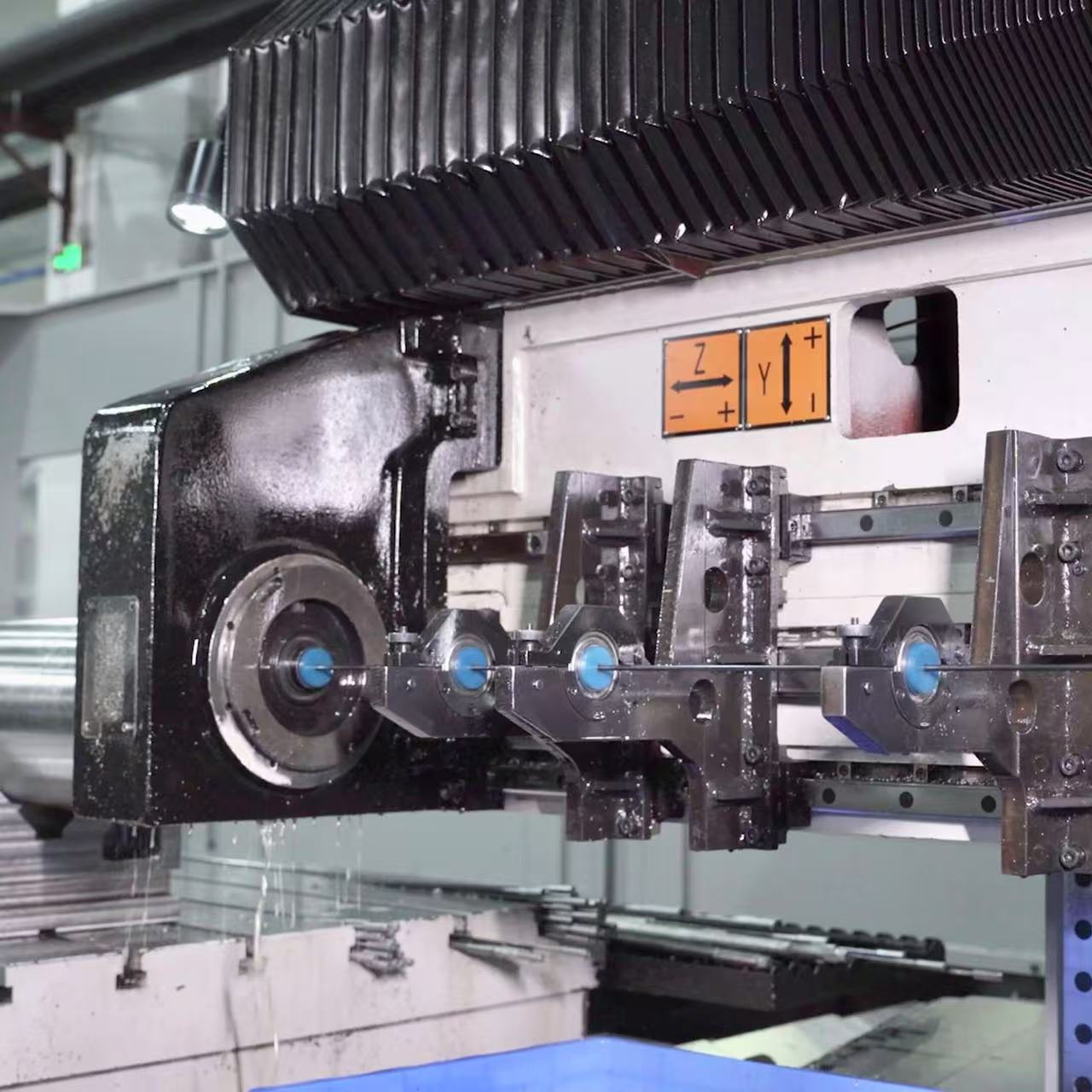

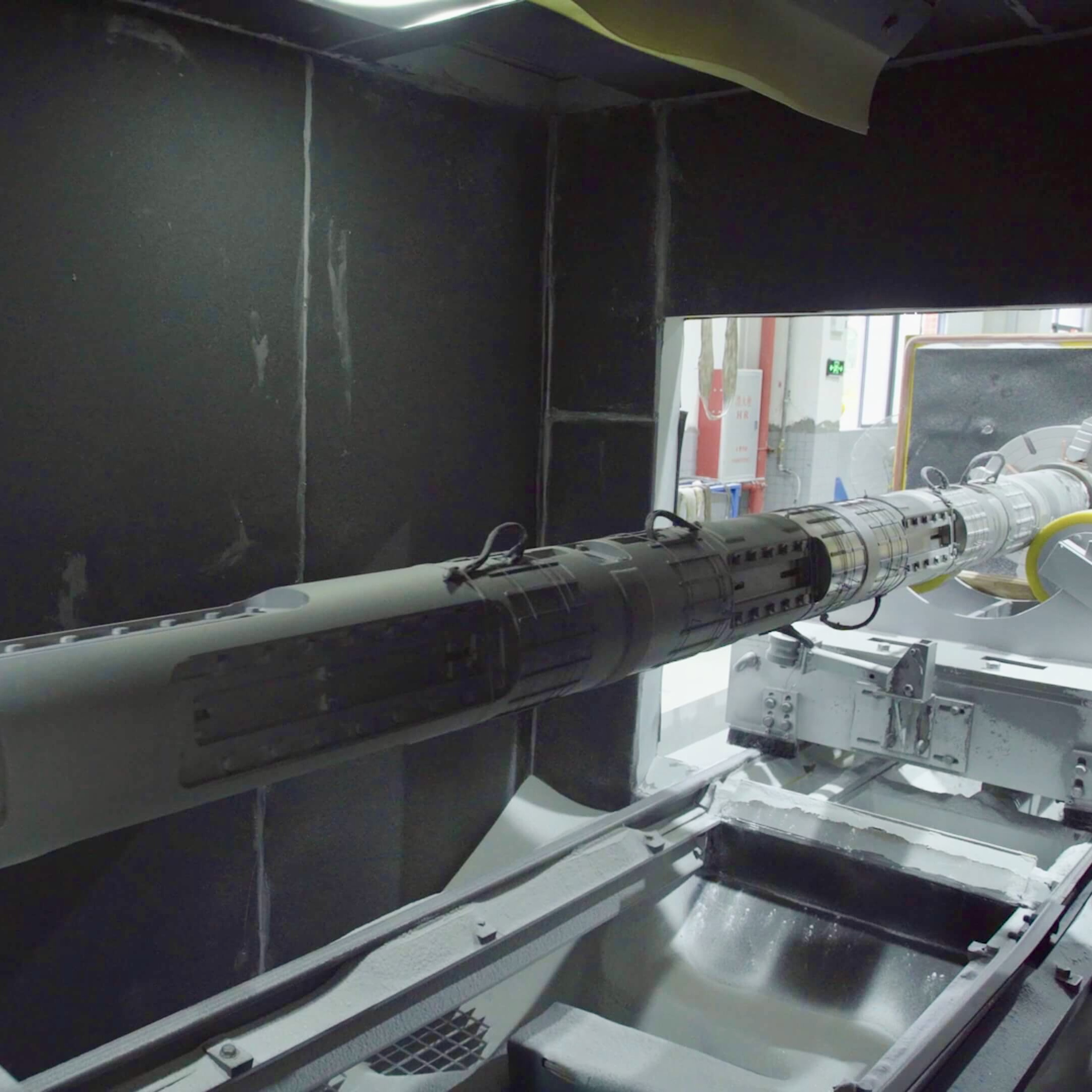

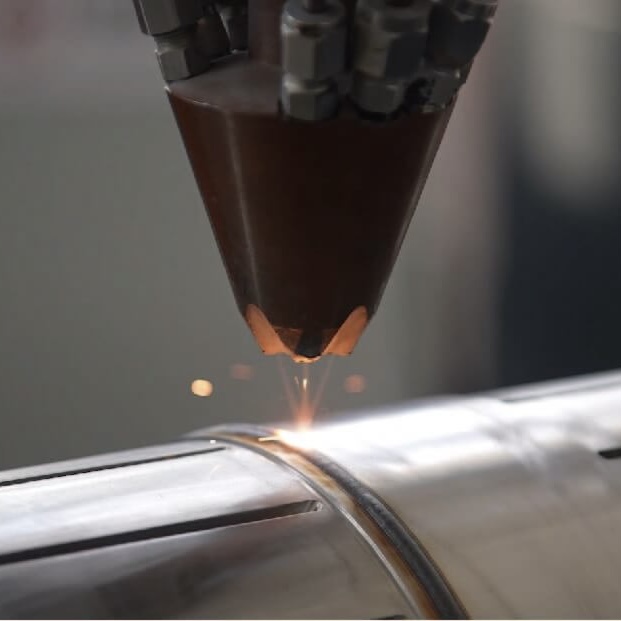

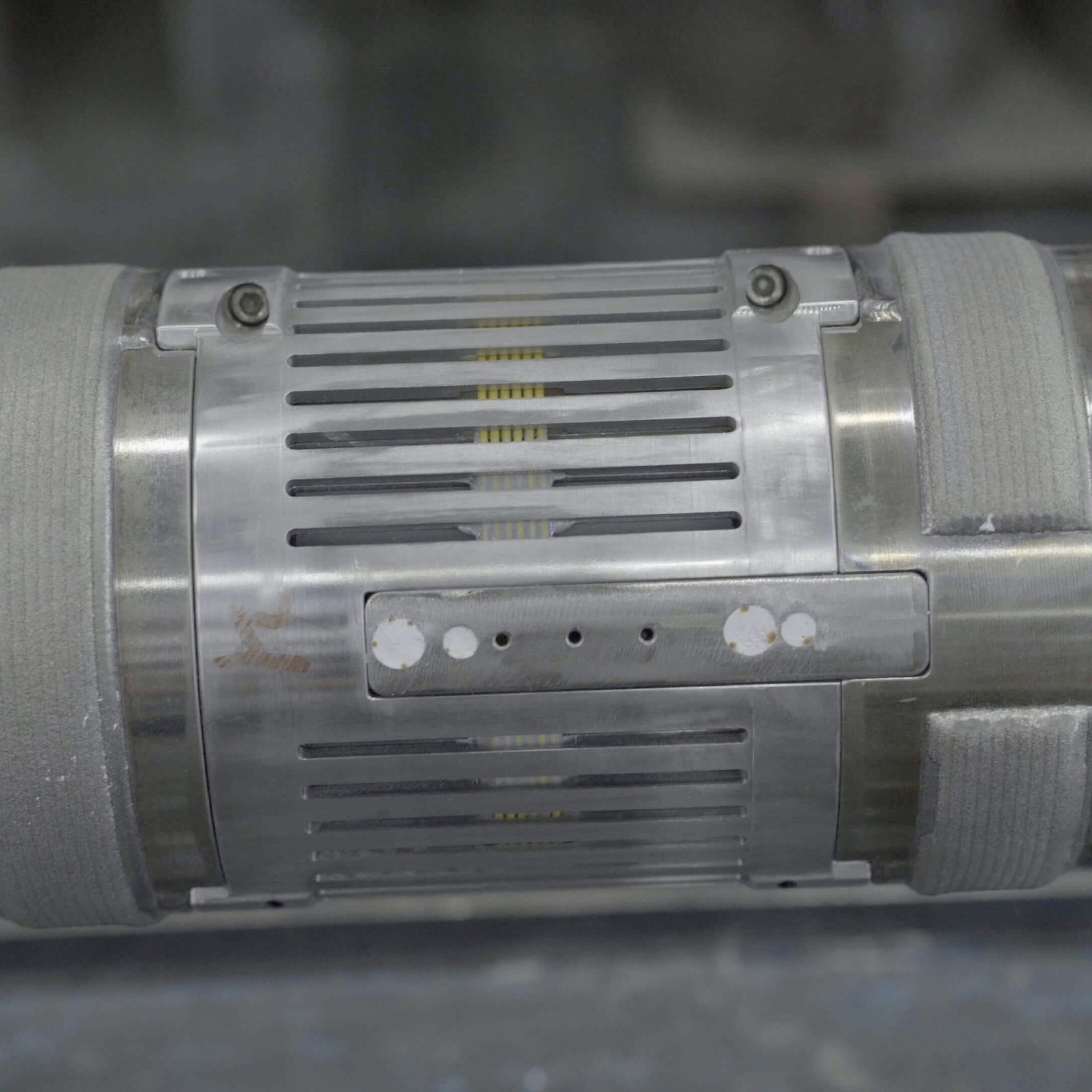

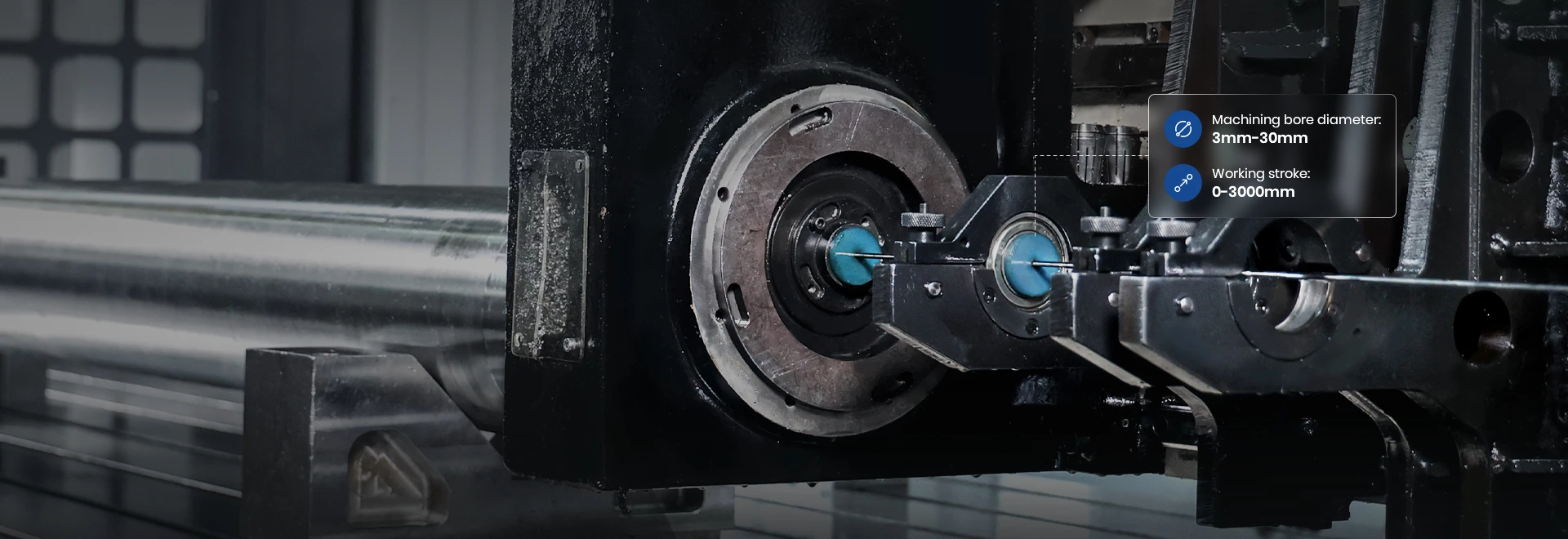

WELLTECH adopts customized inclined hole CNC equipment and special tooling to achieve high-precision spatial inclined hole processing. The processing angle range reaches ±90°, angular error ±3′, and the maximum workpiece diameter is Φ280mm, which can meet the processing requirements of multiple angle holes.

Craft Case Gallery

Explore all gallery

Why us

Explore more

The Industrial Pilot Testing Service Capability

We achieve full-chain integration of prototype production, equipment assembly and intelligent maintenance to ensure full-cycle accurate delivery.

Scale Production

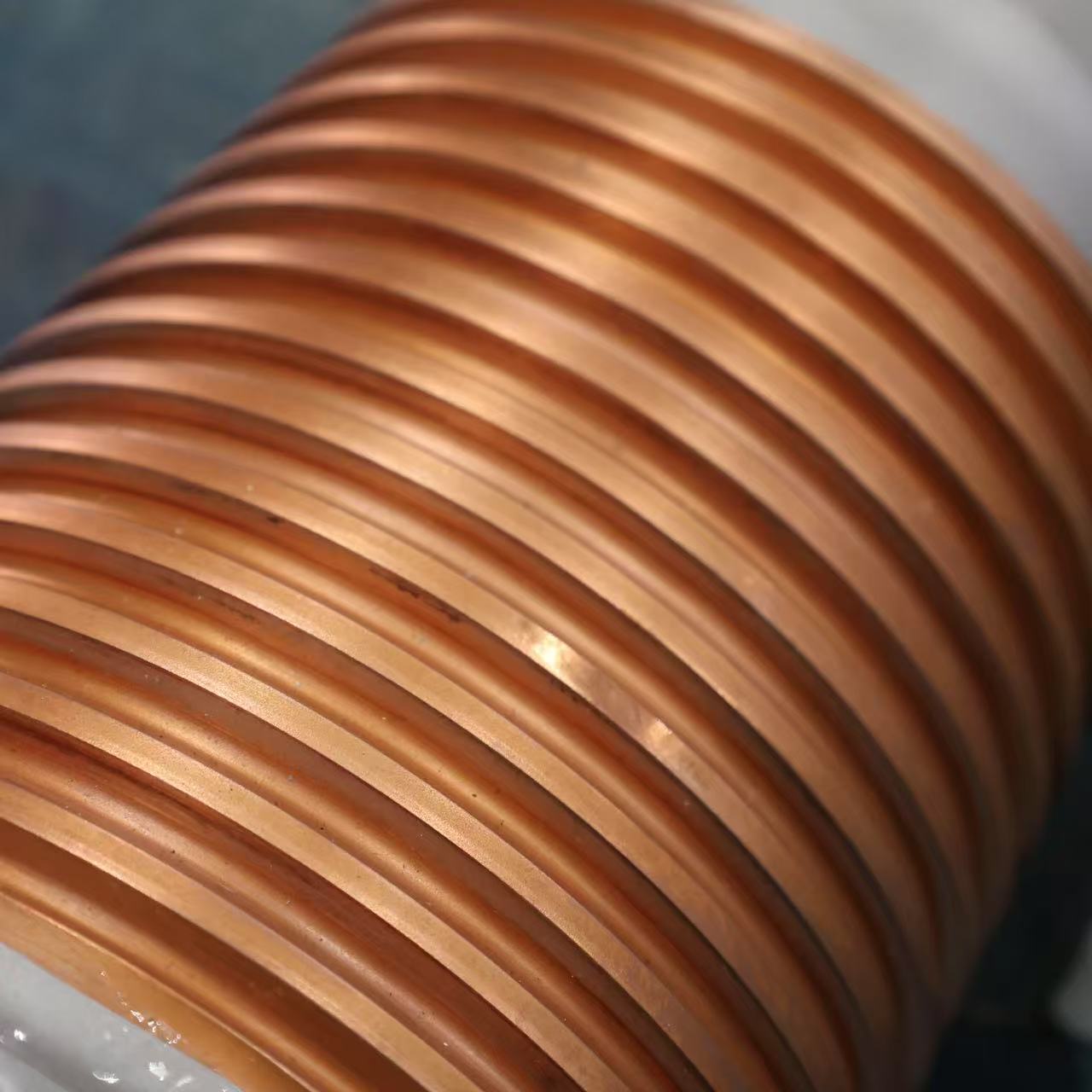

WELLTECH's modern production workshops, standardized process flow and efficient capacity layout enable scale production to meet customer needs with stable quality and batch delivery capability.

Shorten errors with technology and fulfill promises with precision

Let precision manufacturing understand you better - one click quotation, unlock efficient production password

Get a quote now