Quality Management System(American API, German ISO)

WELLTECH has consistently upheld quality as the cornerstone of its corporate competitiveness, and has established a robust quality management system, which has successively obtained the ISO 9001 quality management system certification of Rheinland, and the API Spec Q1, API-7-1 and API-7-2 certifications of the American Petroleum Institute.

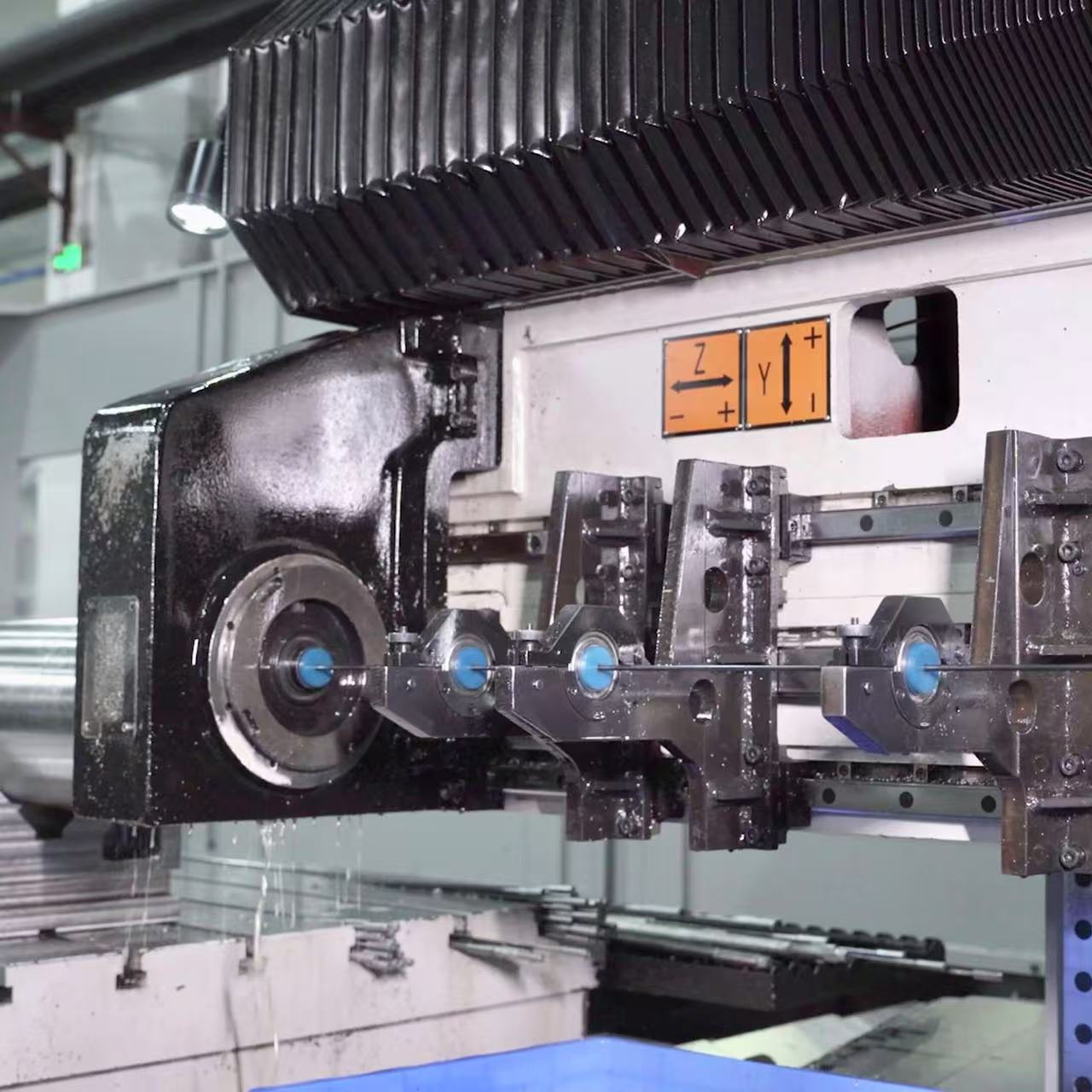

Quality Control Services

The company strictly executes the First Article Inspection (FAI) management system, implements inter-process inspection during the production process, conducts precision verification after the output of finished products, and executes key processes such as three-coordinate precision measurement and reliability test analysis. Through the rigorous production management system and strict quality control measures throughout the whole process of production and delivery, we ensure the excellence of each link, so that the whole process meets the international high quality standards.

Six major experimental platforms

High-temperature and High-pressure Test Facility

Simulating the downhole environment, it can realize testing the sealing performance of the instrument, instrument strength and instrument working performance under the environment of maximum temperature of 180℃ and maximum pressure of 180MPa, so as to improve the factory qualification rate of instruments and the success rate of the well.

Water Circulation Test Facility

This system is the first dual-pump large-displacement water circulation test system in China, with a maximum displacement of 6m³/min, which can meet the factory water circulation needs of the "Xuanji" system instruments, while taking into account the large-displacement water circulation test needs of scientific research instruments.

Non-magnetic Scale and Calibration Facility

The building around the test site is larger than 50 meters, all wooden structure, to achieve a completely non-magnetic test environment, the facility is equipped with magnetometer monitoring equipment and special non-magnetic rotary table, used for the sensor temperature drift calibration of the directional probe, the overall calibration of the probe and testing.

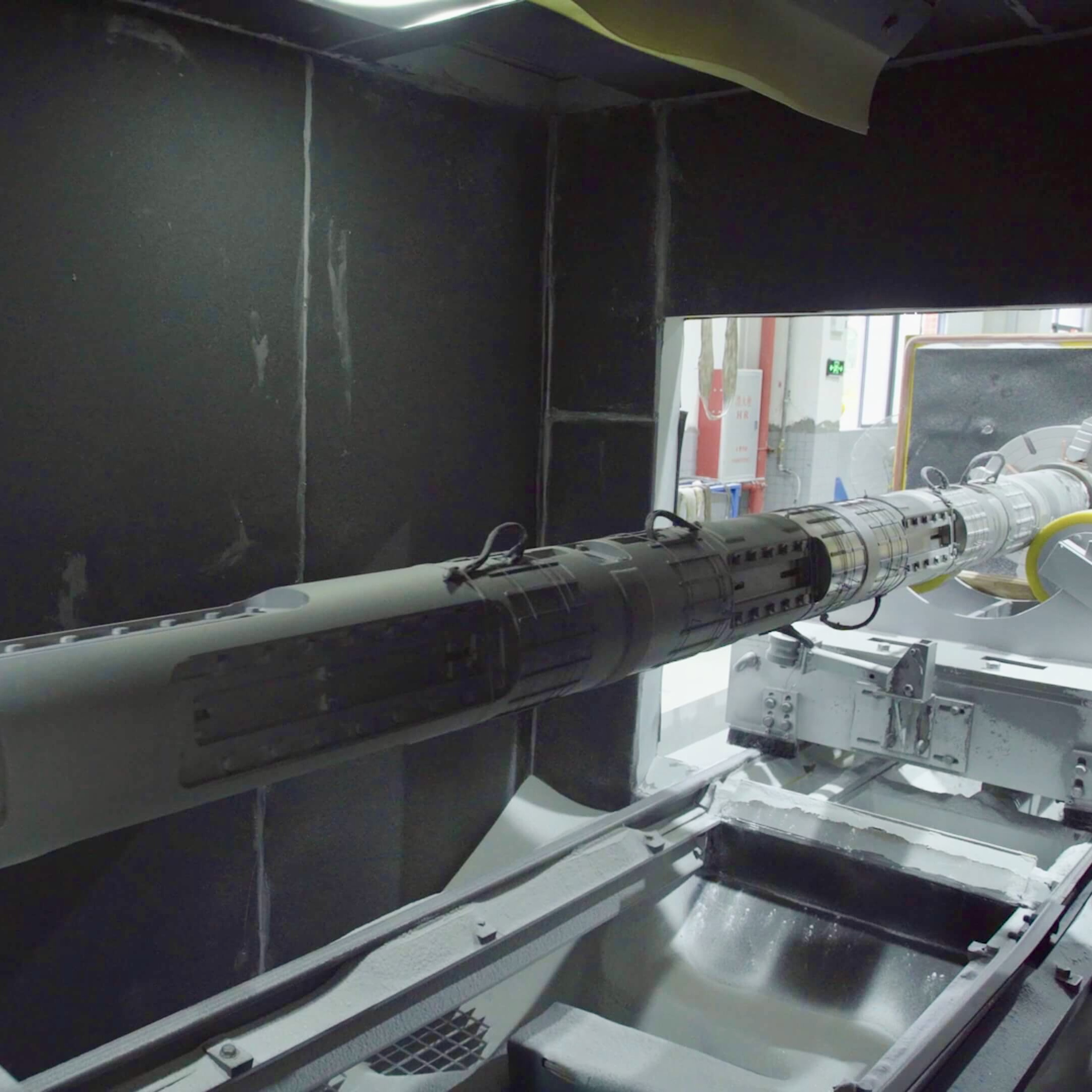

60T Double Shunt Vibration Table

It is mainly used for vibration simulation test of instruments while drilling, testing the reliability of instruments in strong vibration environment, meeting the requirements of radial and axial vibration test of instruments, and achieving the longest 12 meters and the weight of 2T follow-drill instrument can be tested with acceleration of 20G vibration.

High Acceleration Stress and Screening Test System

This system is capable of applying single or multiple stress factors to critical electronic components and circuit boards, conducting dual integrated environment tests with temperature perturbation under high acceleration, and conducting batch screening inspection and reliability testing of circuits to improve the reliability of downhole instrumentation operations.

Non-Inductive Scaling of Resistivity

This facility comprises a resistivity anisotropy simulation well, a non-sensitive calibration frame, an azimuth rotation testing frame, and a tower crane. It is designed for the calibration and functional testing of while-drilling resistivity instruments ACPR and DWPR, including air zeroing, saltwater scale, and azimuth function verification.

Online Technical Support

Machining process consulting, equipment troubleshooting, CNC programming guidance, software operation support, etc., through real-time communication (e.g., video calls, online work orders), remote diagnostic tools or knowledge base sharing, to help customers quickly solve the relevant technical problems

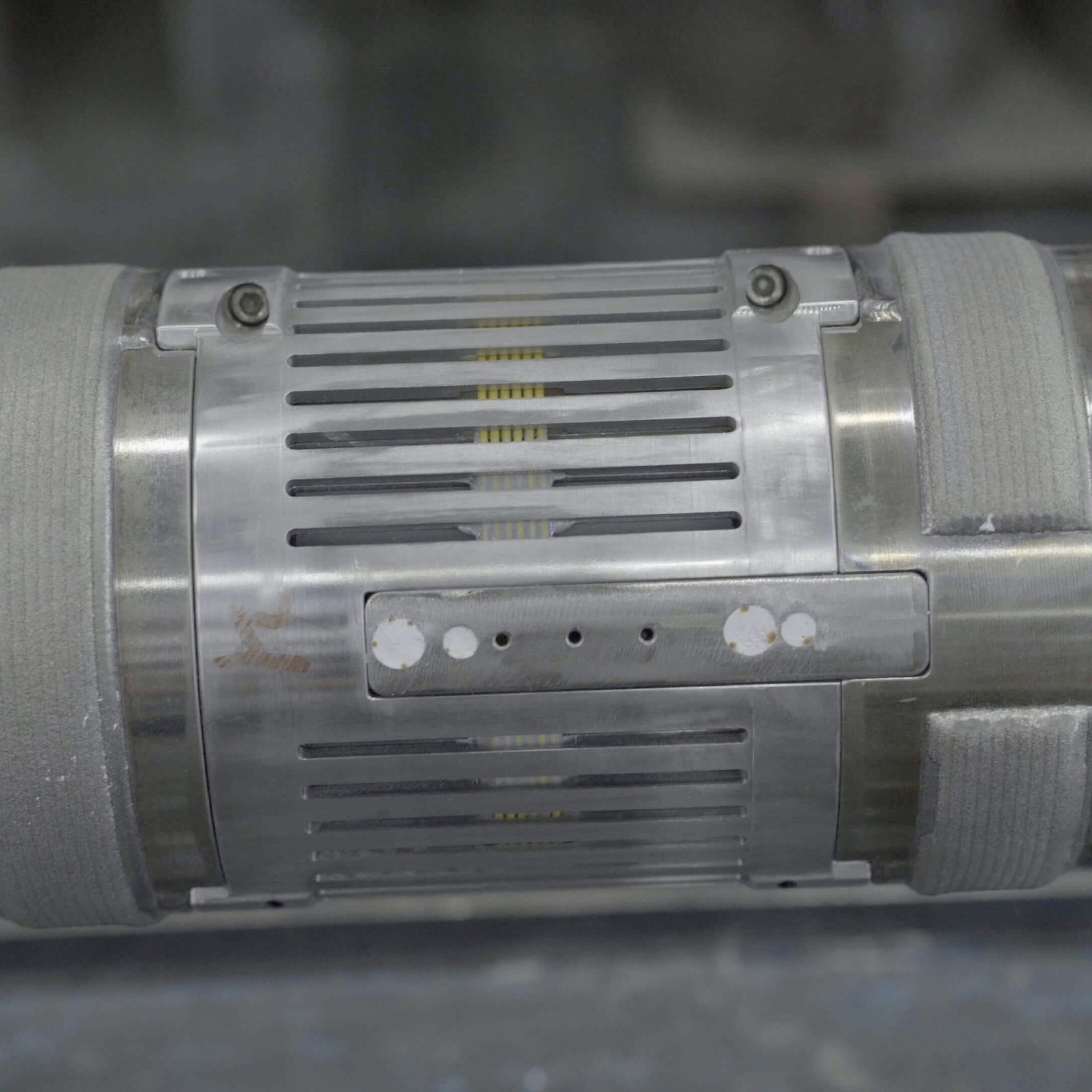

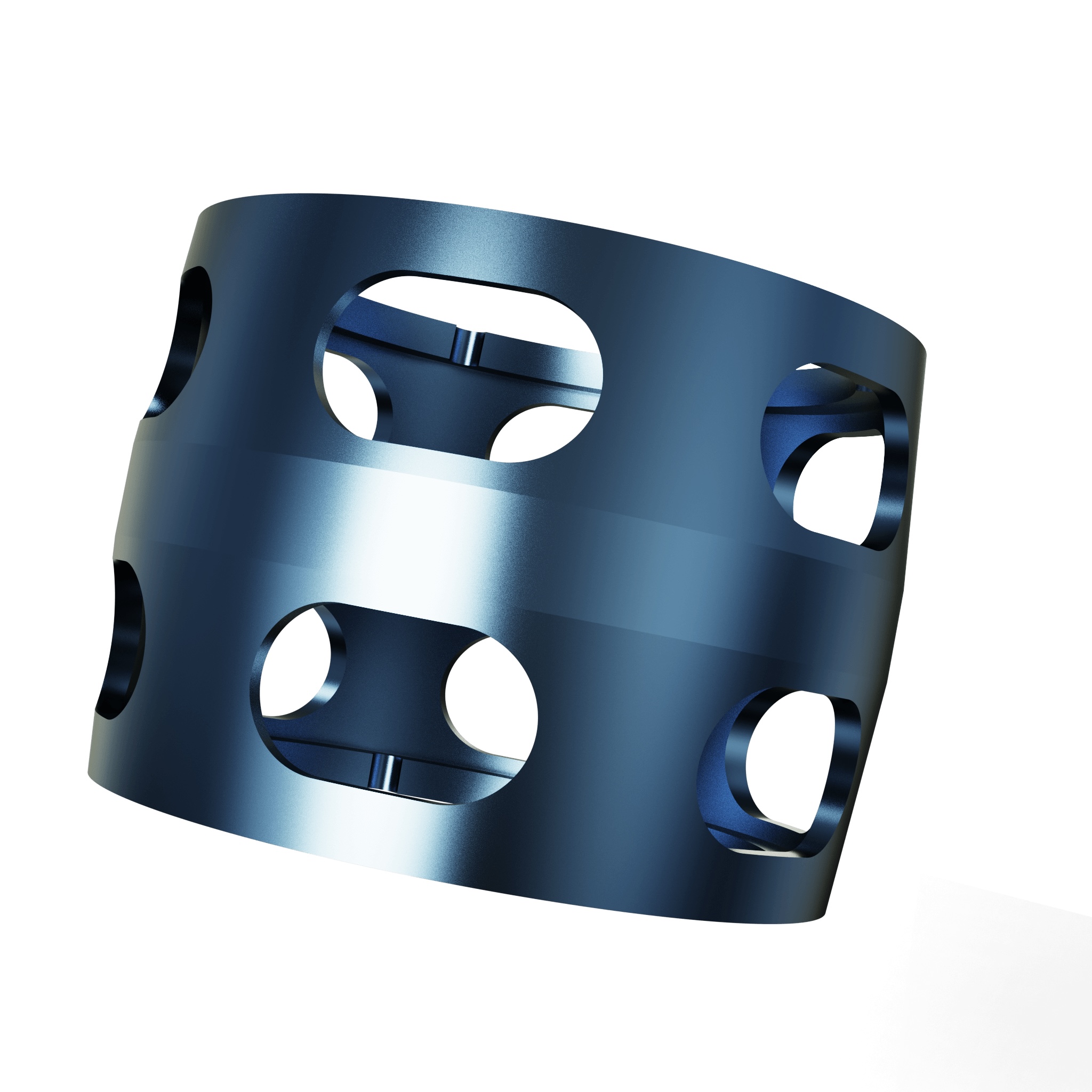

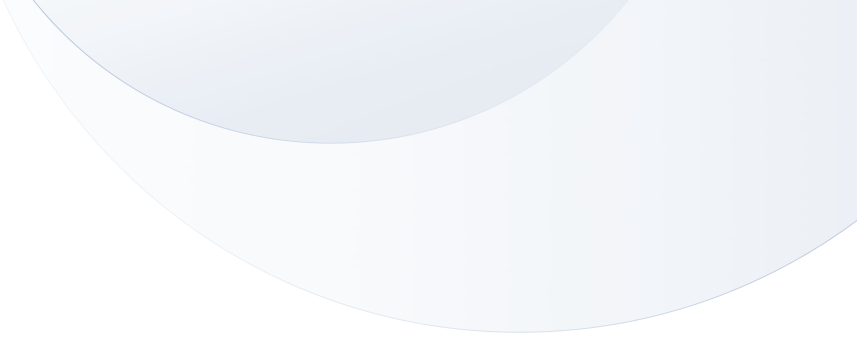

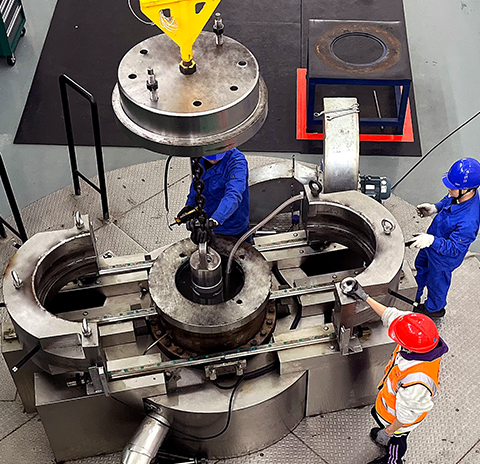

Equipment Assembly

The assembly workshop of WELLTECH covers an area of nearly 7,500 square meters, with five production areas:the rotary guidance production area, the drilling instrument production area, the high-speed drilling production area, the drilling induction instrument production area, and the electronic welding and assembly area, and equipped with 300㎡ of class 10,000 dust-free workshop and 200㎡ cleaning room, and realizes the whole process record from incoming materials, assembly, inspection, warehousing, and delivery, with the strong parallel operation capability of the production line, which can simultaneously carry out mechanical assembly and electronic assembly of multiple types of products.

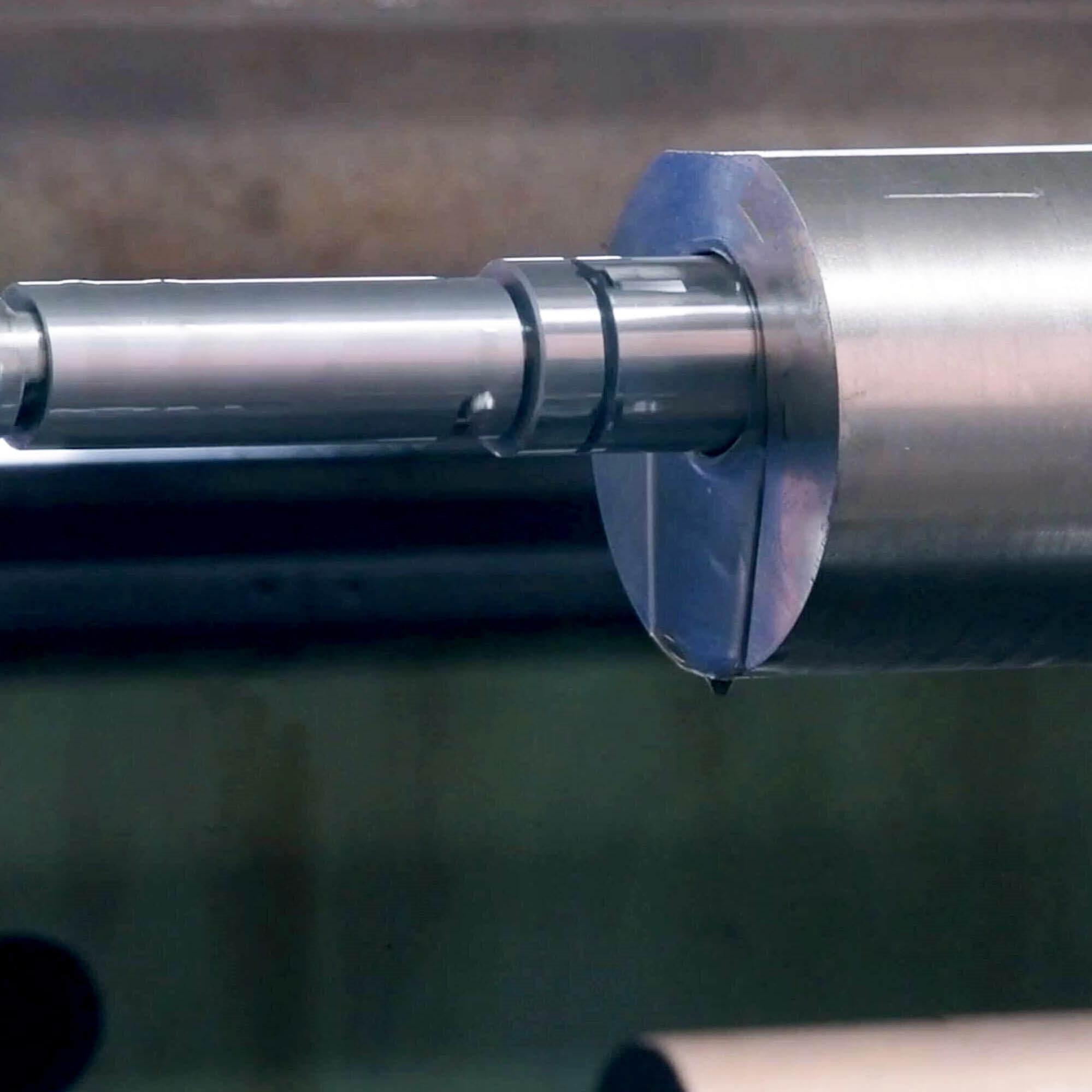

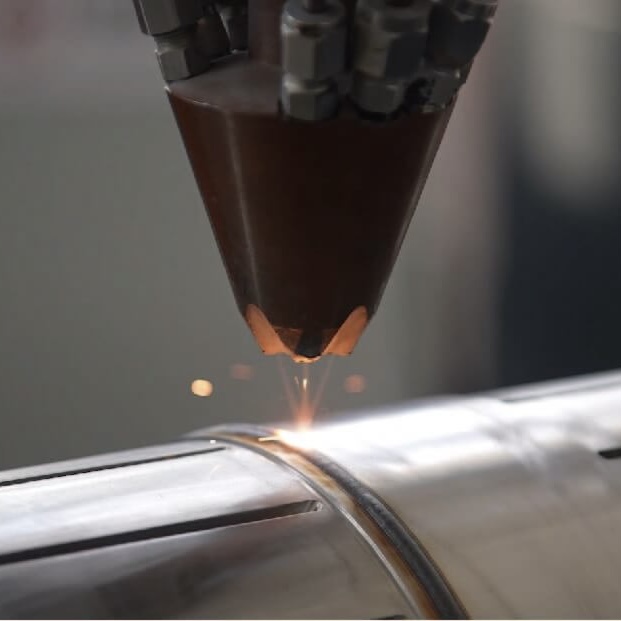

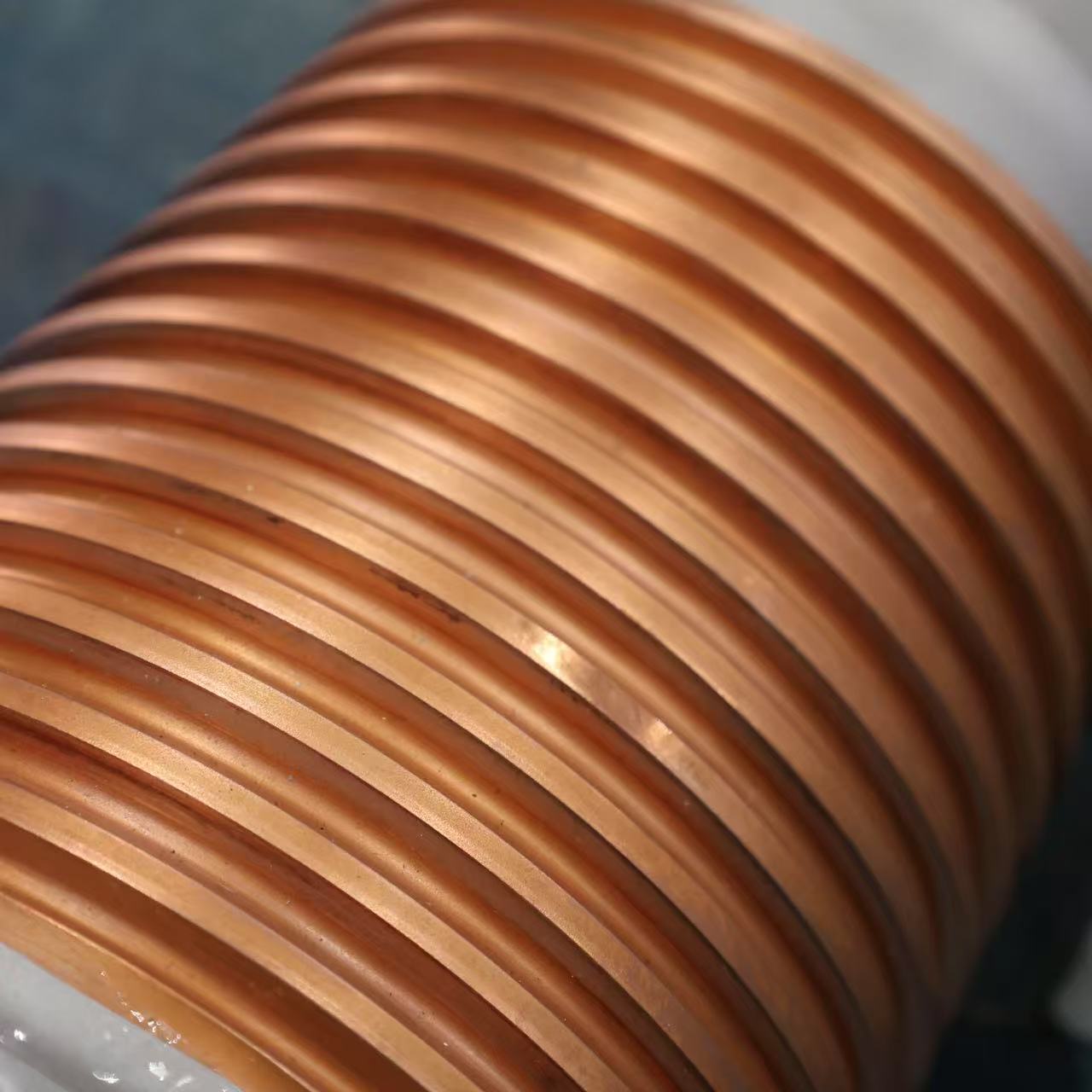

New Process R&D

Through continuous new process research and development, we break through the bottlenecks of traditional technologies to provide more competitive solutions for our customers.