Technical Capability Matrix 01

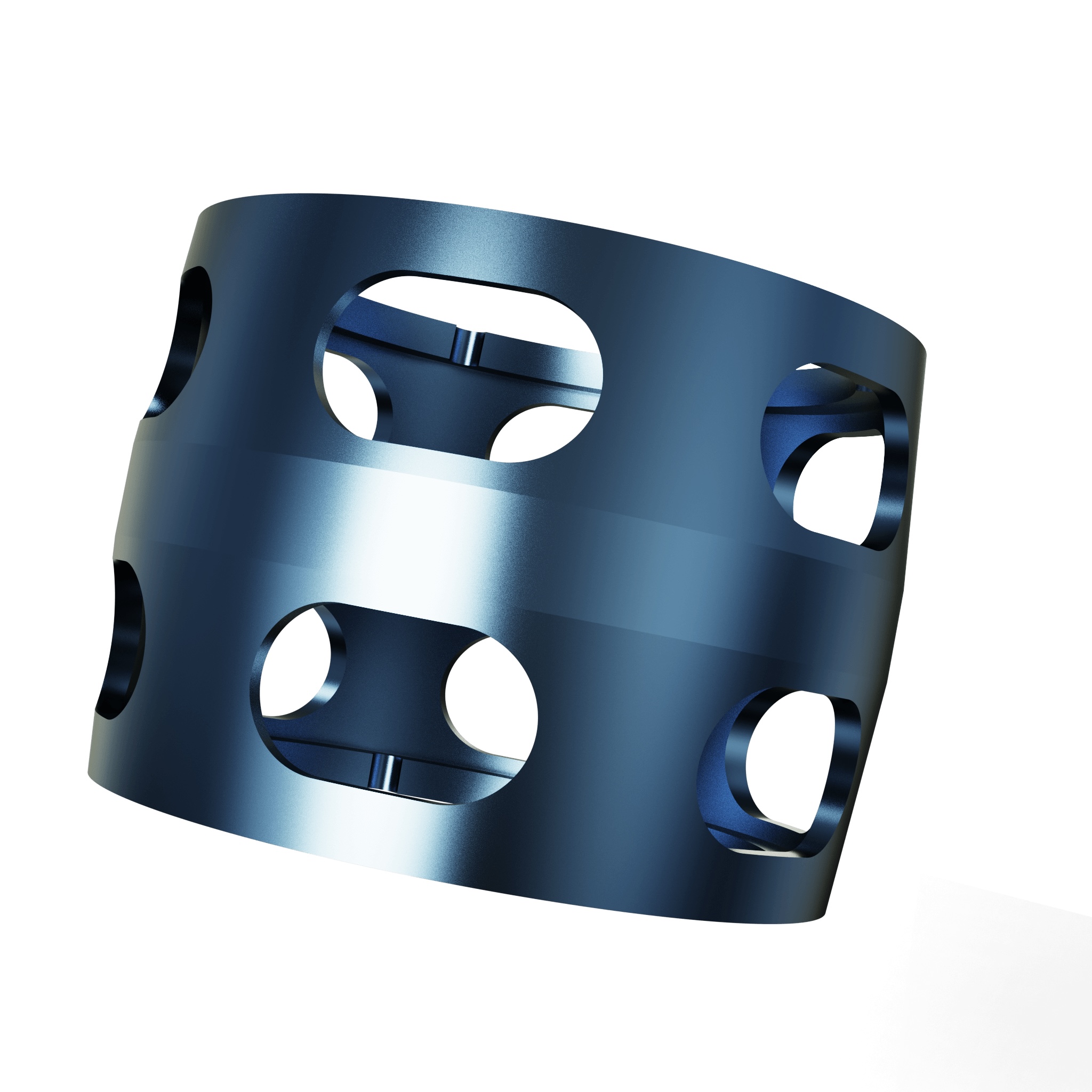

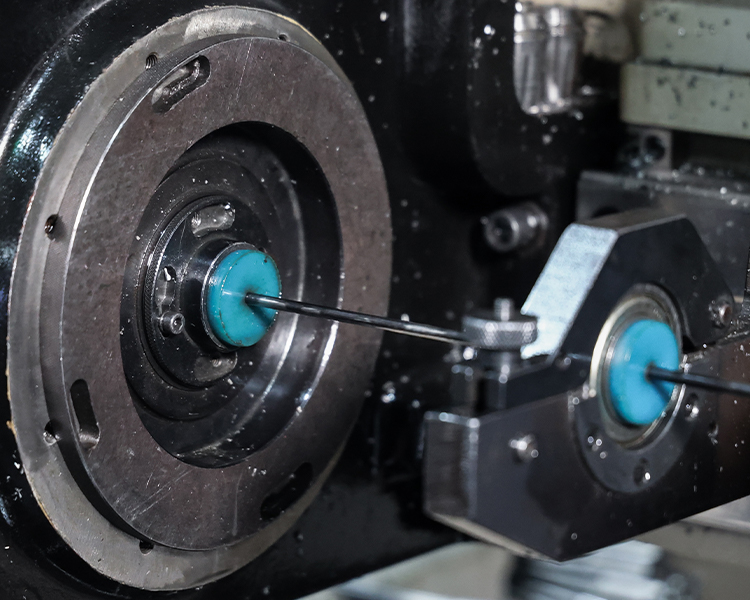

Precision Manufacturing Process

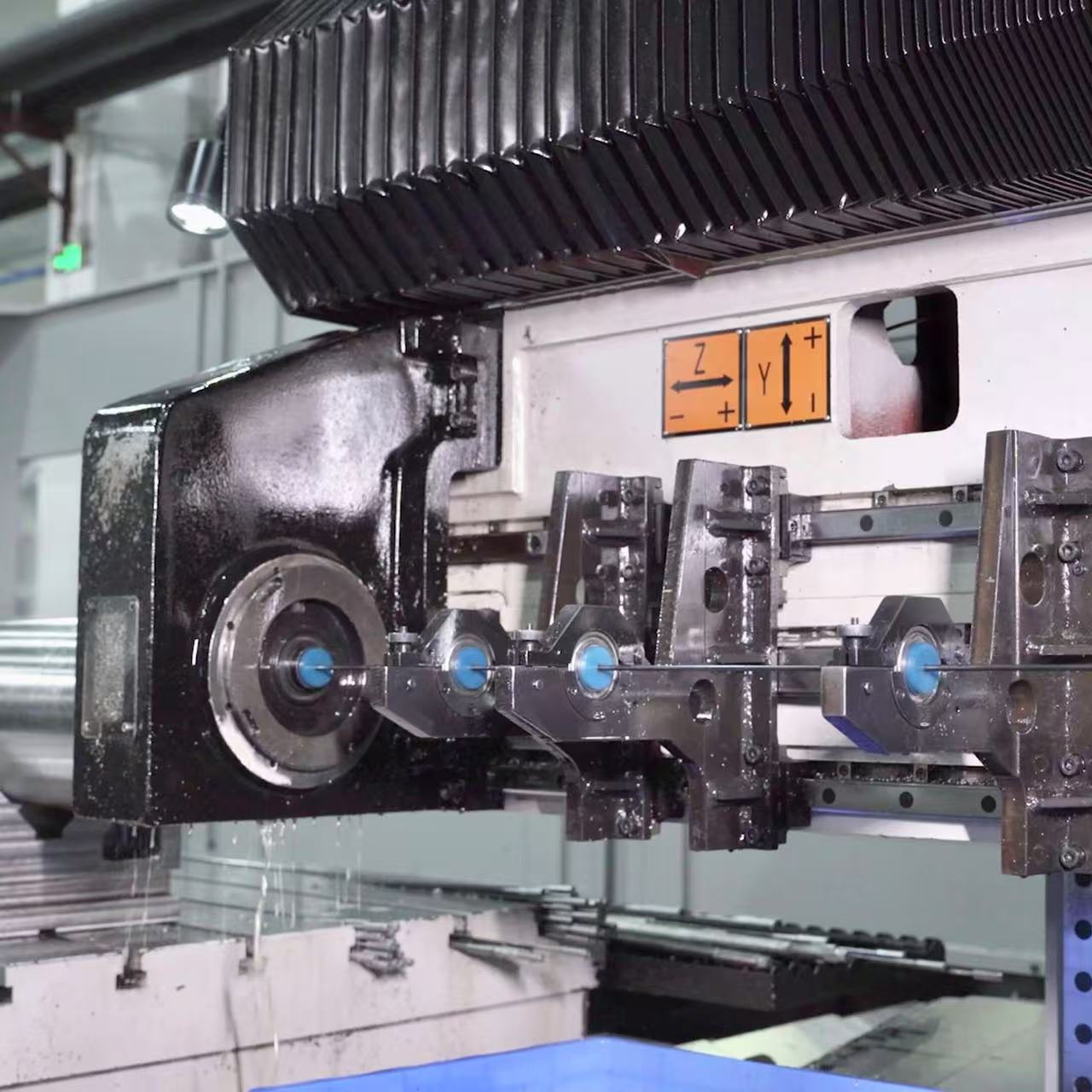

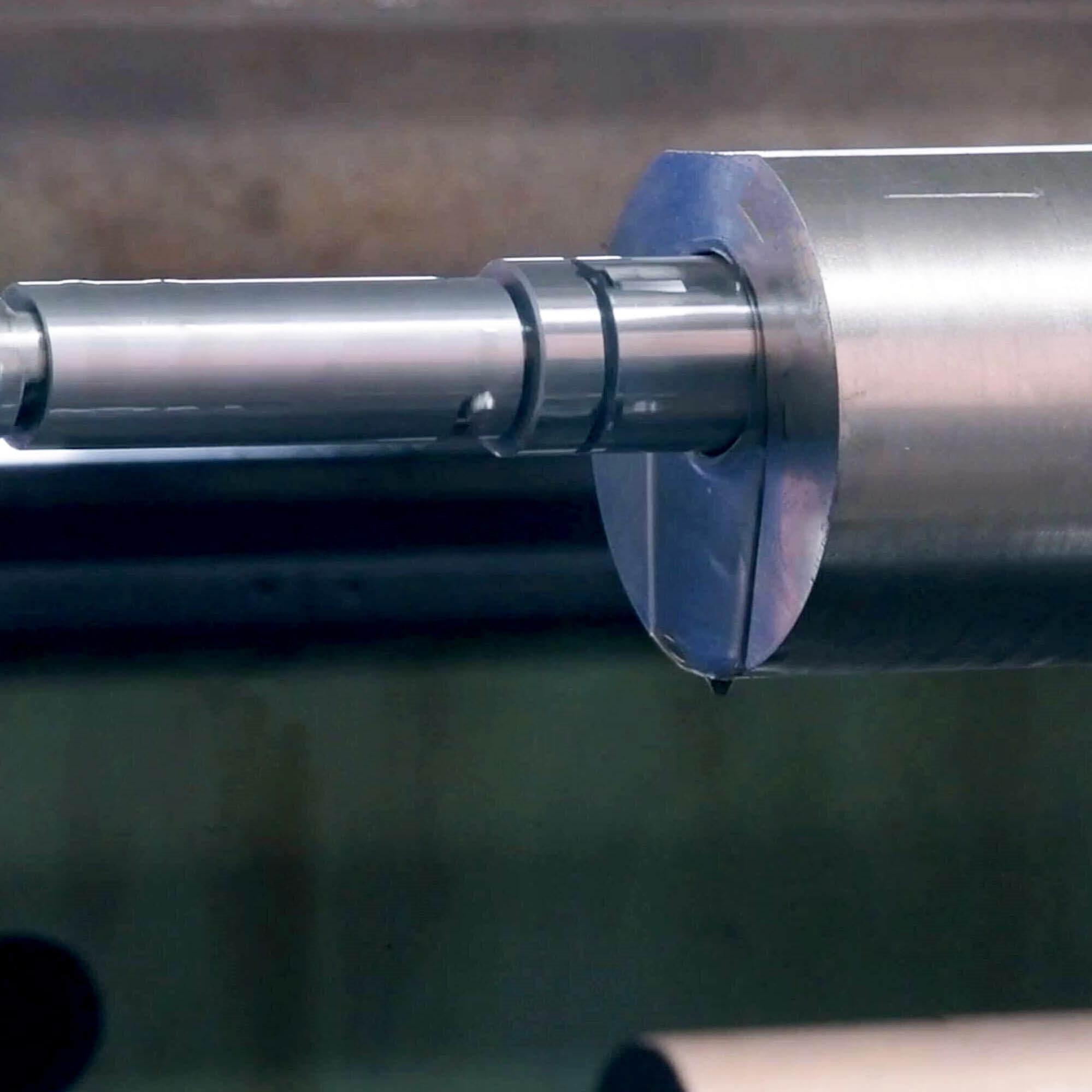

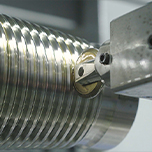

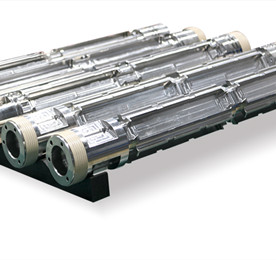

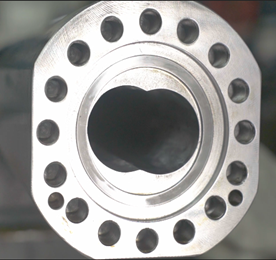

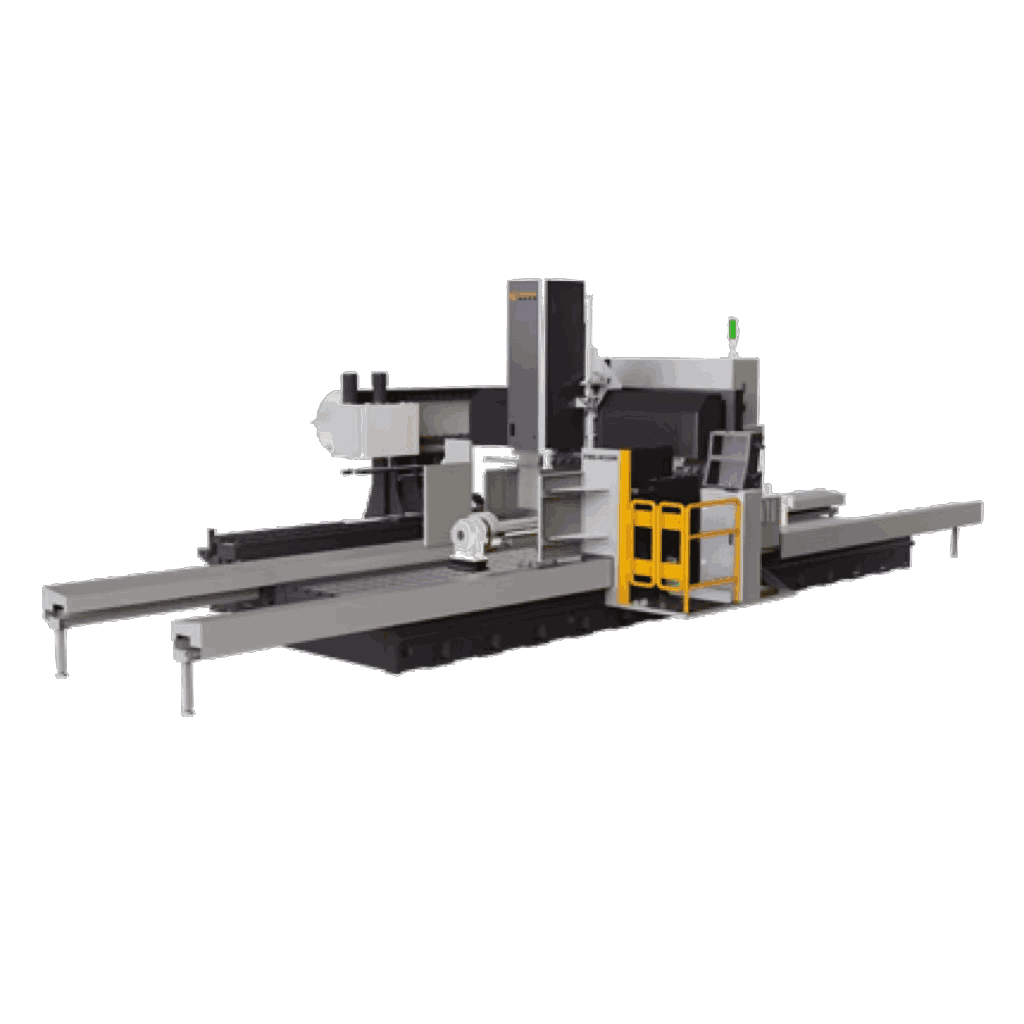

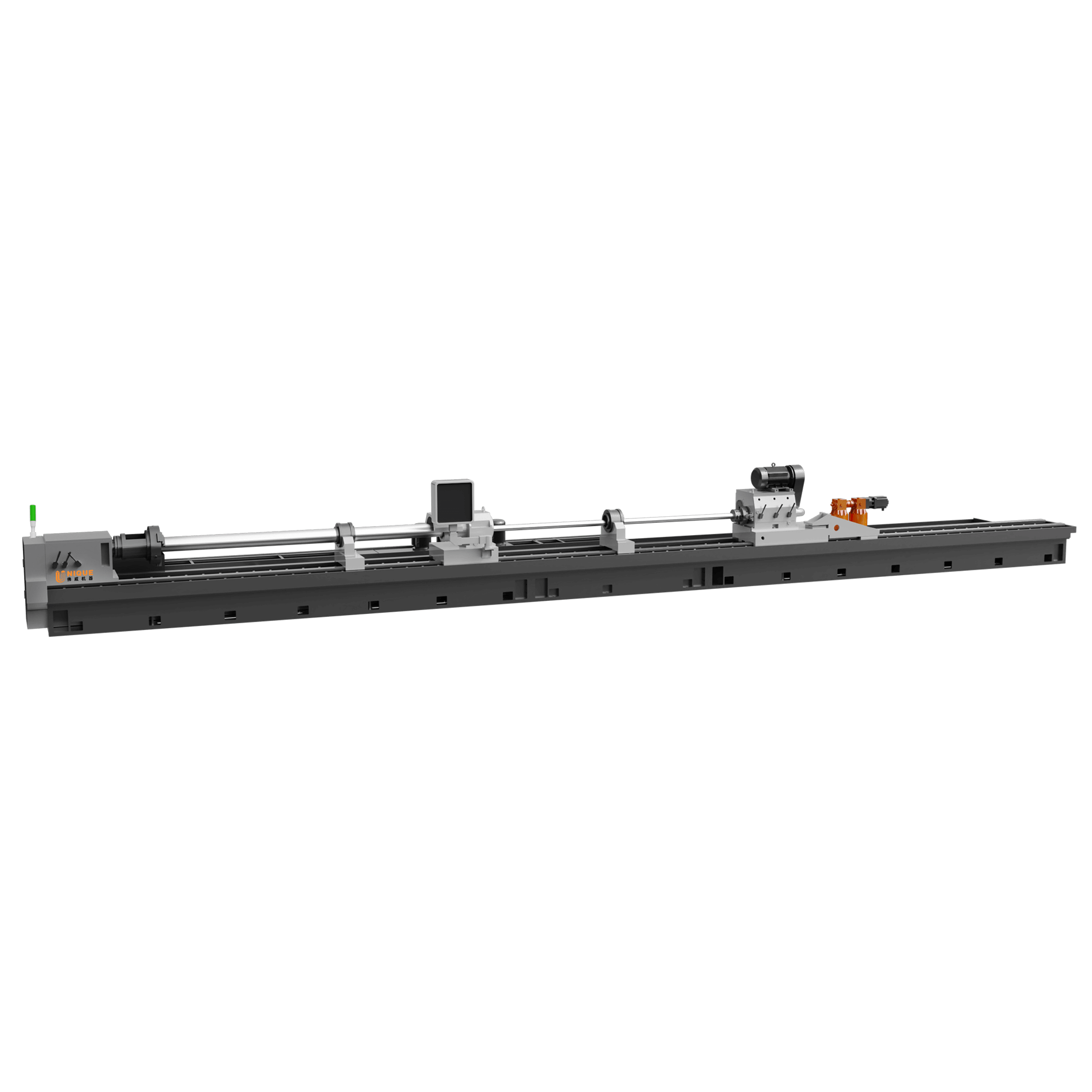

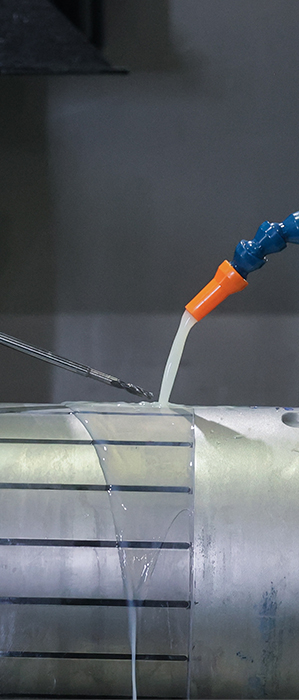

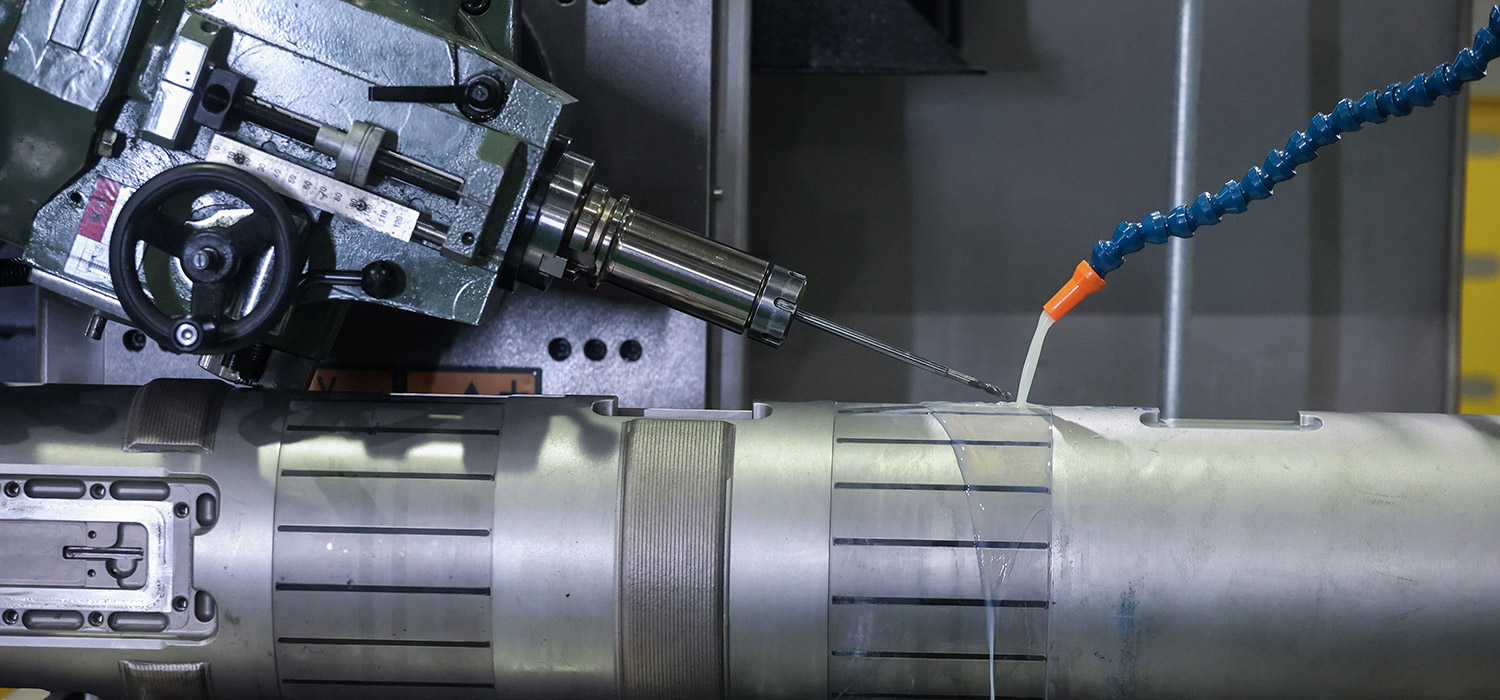

WELLTECH has mastered more than 40 kinds of independent precision manufacturing processes, covering core technologies such as deep hole machining, ultra-deep gun drilling, eccentric hole machining, deep hole EDM, etc. Through customized equipments, special fixtures and fittings and optimized processes, the company is able to efficiently complete the machining tasks of difficult materials, complex structures and high-precision requirements, with excellent performance in machining accuracy, surface quality and process stability to meet the diversified high-end manufacturing needs.

Explore moreTechnical Capability Matrix 02

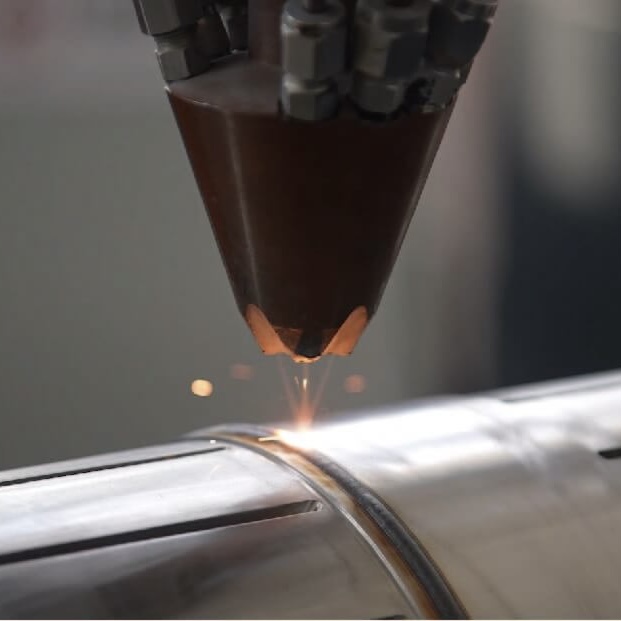

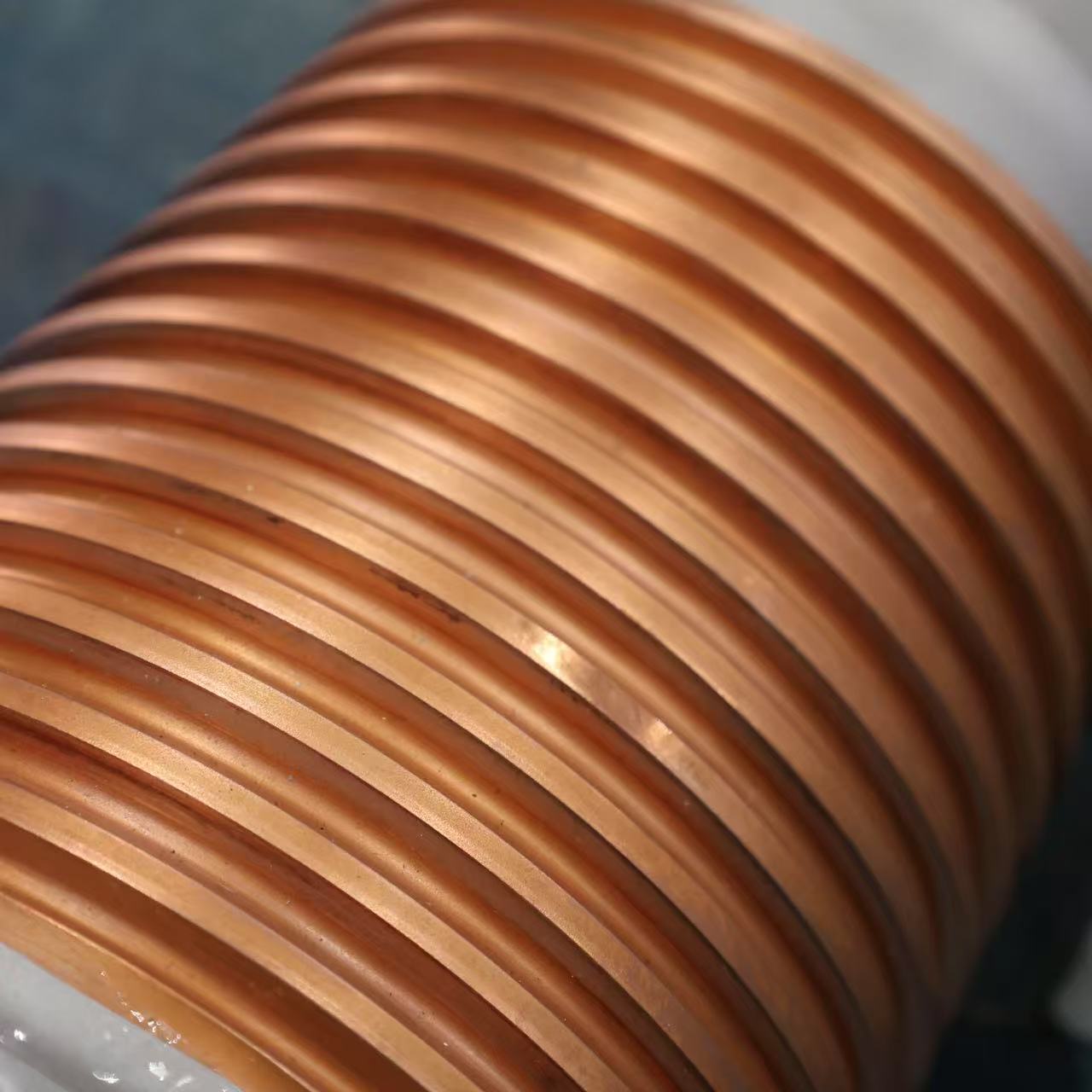

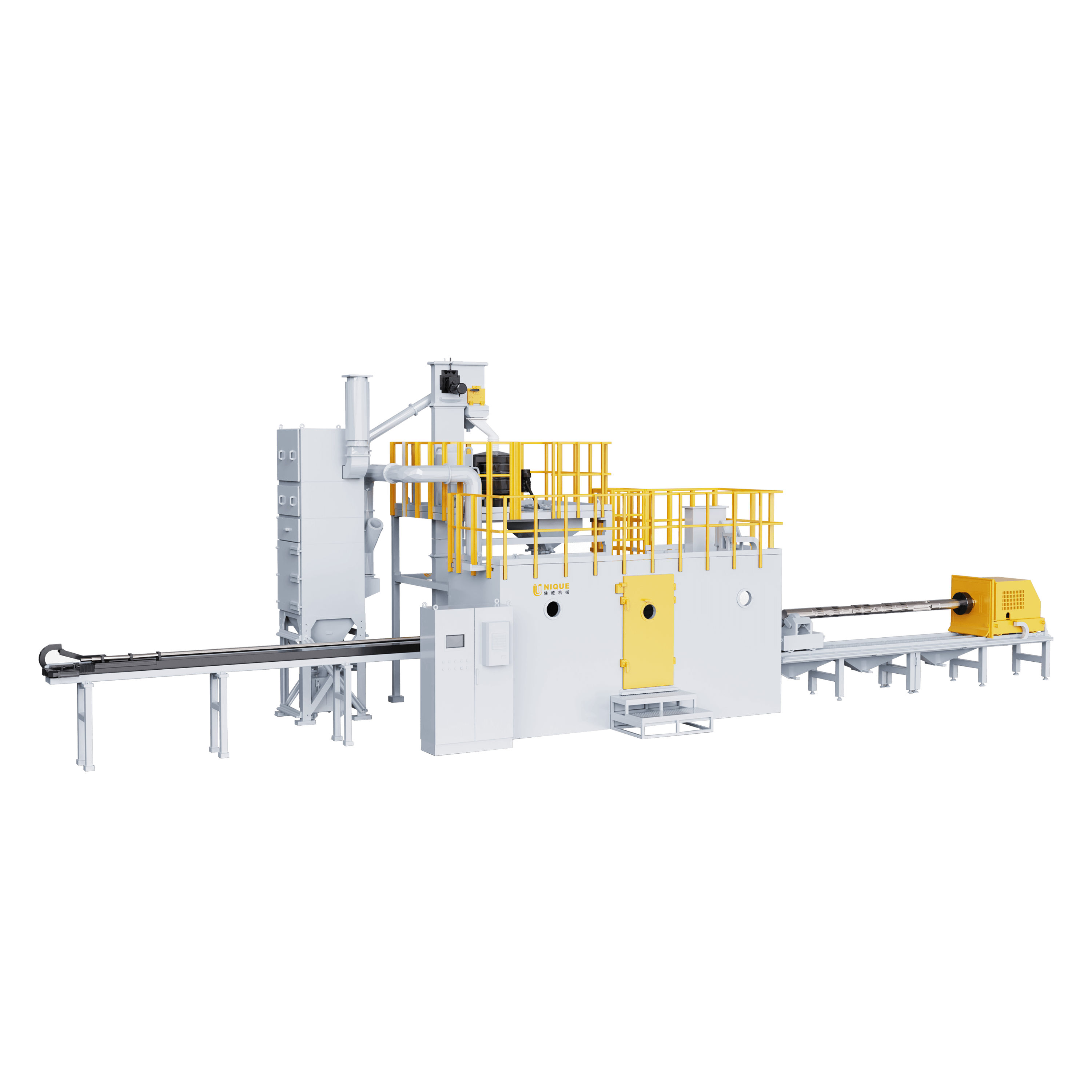

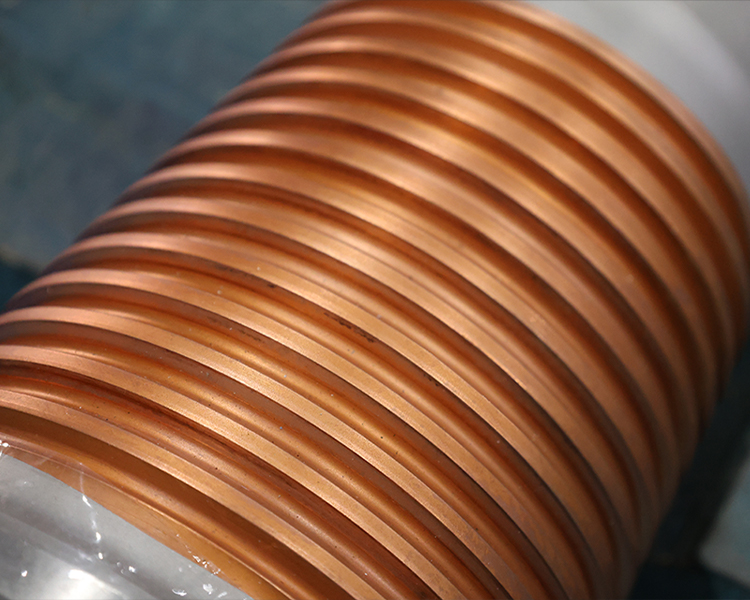

Special Arts And Crafts

WELLTECH has mastered multiple specialized process technologies, including supersonic flame spraying (HVOF), shot peening, laser cladding, vacuum antenna potting and so on. These processes can significantly improve the wear resistance, corrosion resistance, fatigue resistance and other properties of the parts, and are suitable for high-precision, high-demand surface treatment and functional strengthening. Through independent R&D and process optimization, the company is capable of meeting special requirements for material surface performance in aerospace, electronic components, high-end equipment and other fields, providing customized specialized process solutions.

Explore more

200+ Large-scale advanced equipment

Industrial pilot service capability

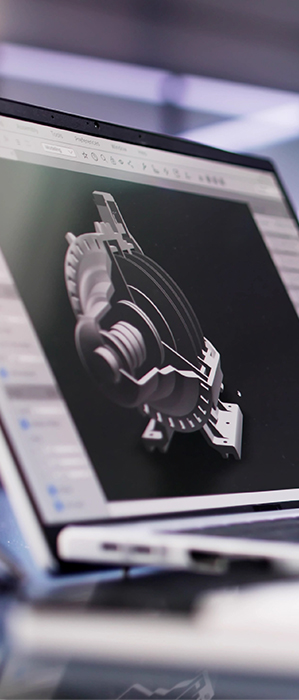

Prototype Design

Manufacturing

Equipment assembly

Quality Control

Maintenance Services

Prototype Design

WELLTECH possesses innovative R&D capabilities for complex structural components to address customization needs.

Manufacturing

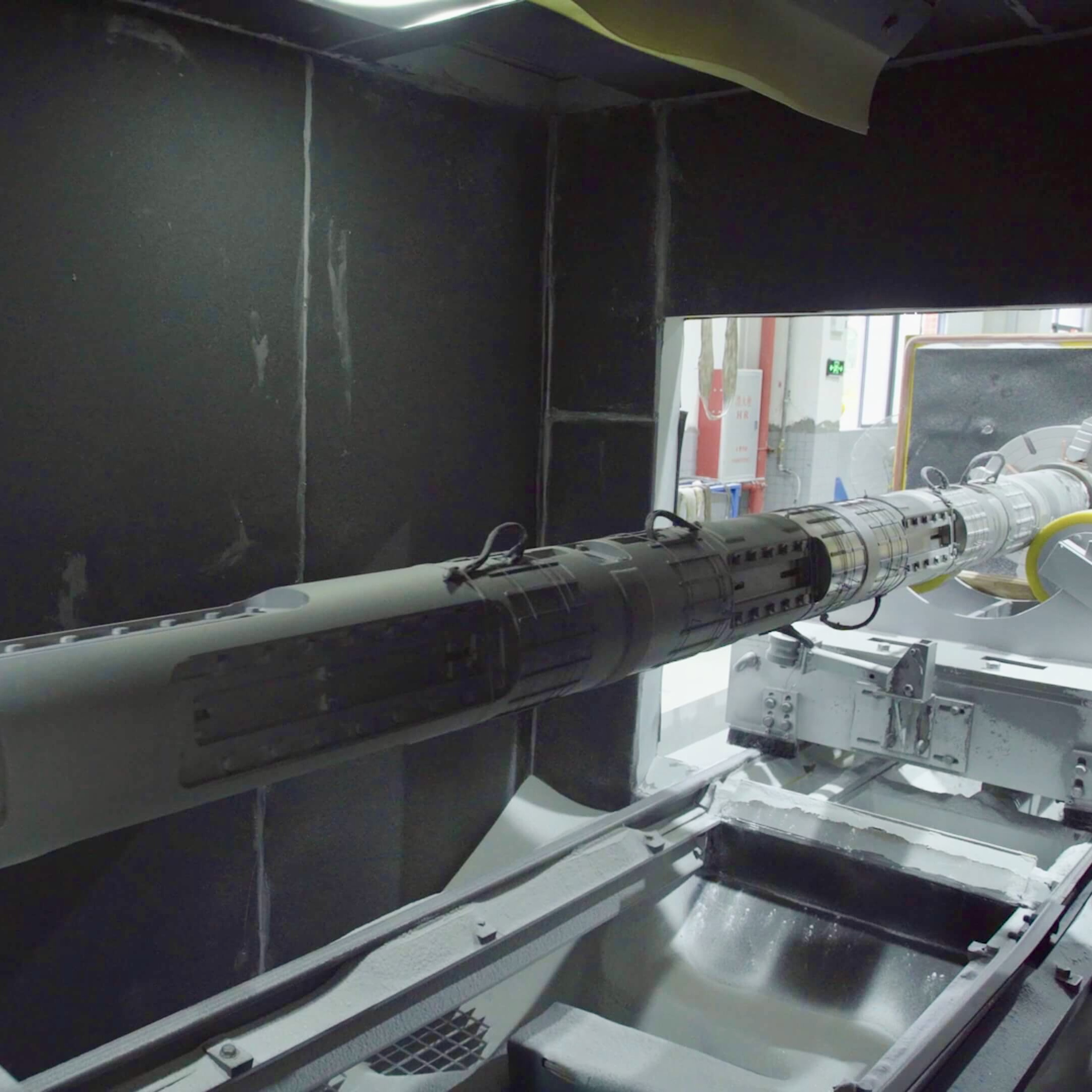

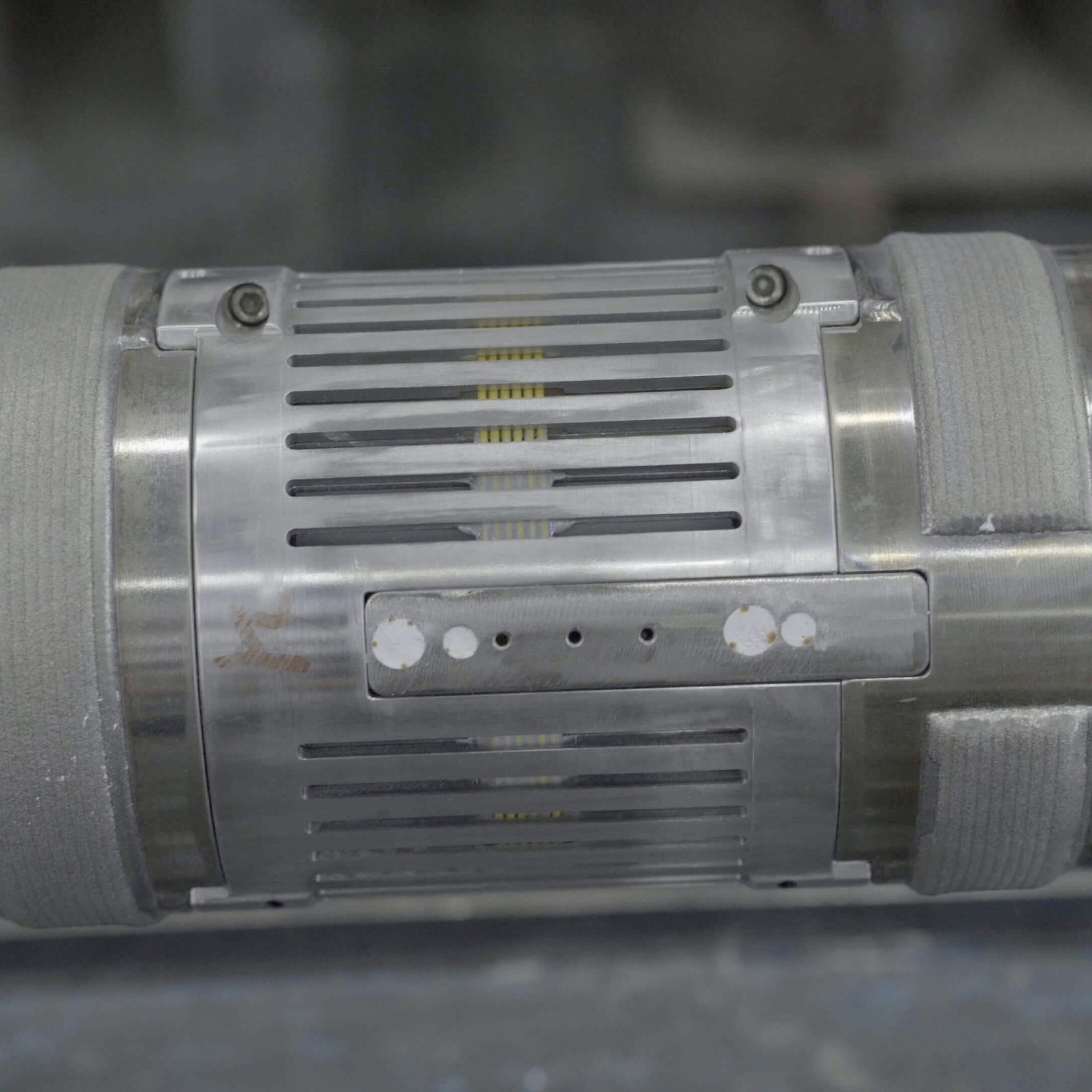

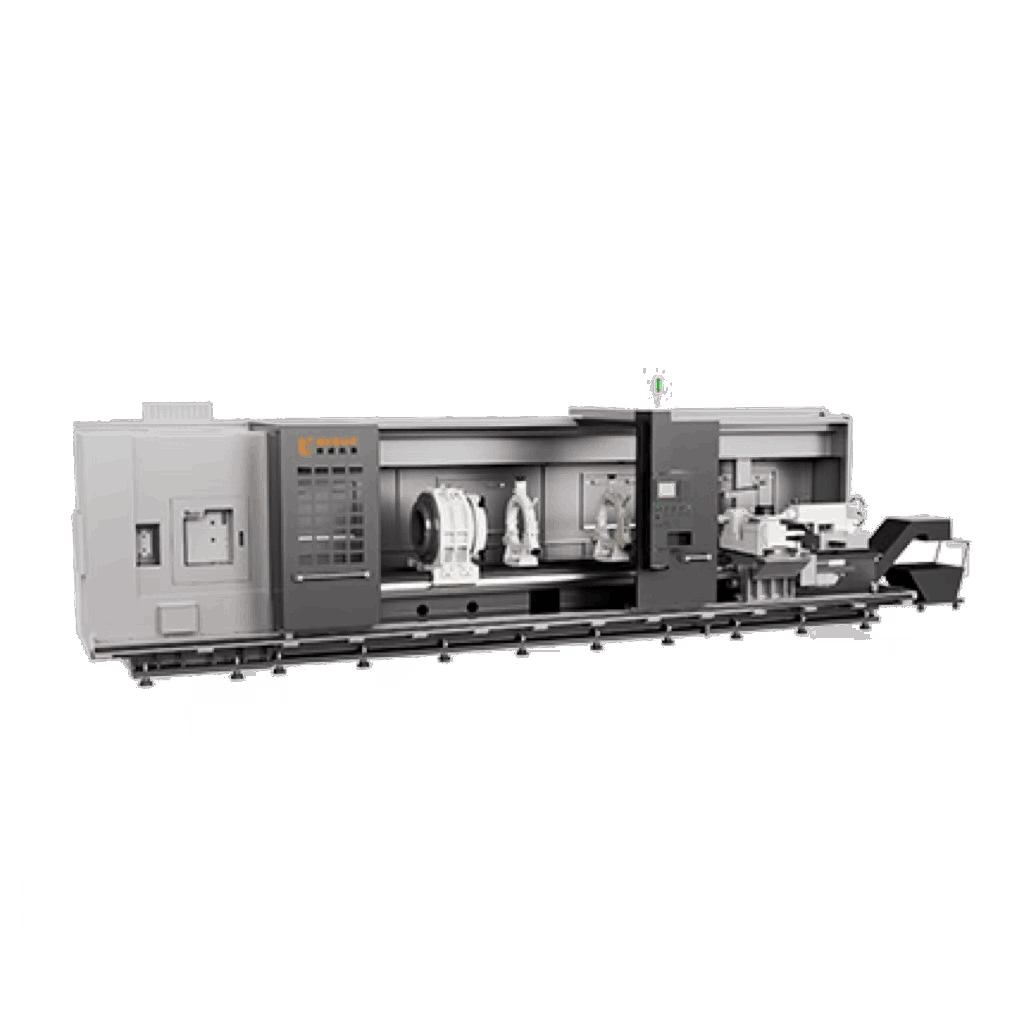

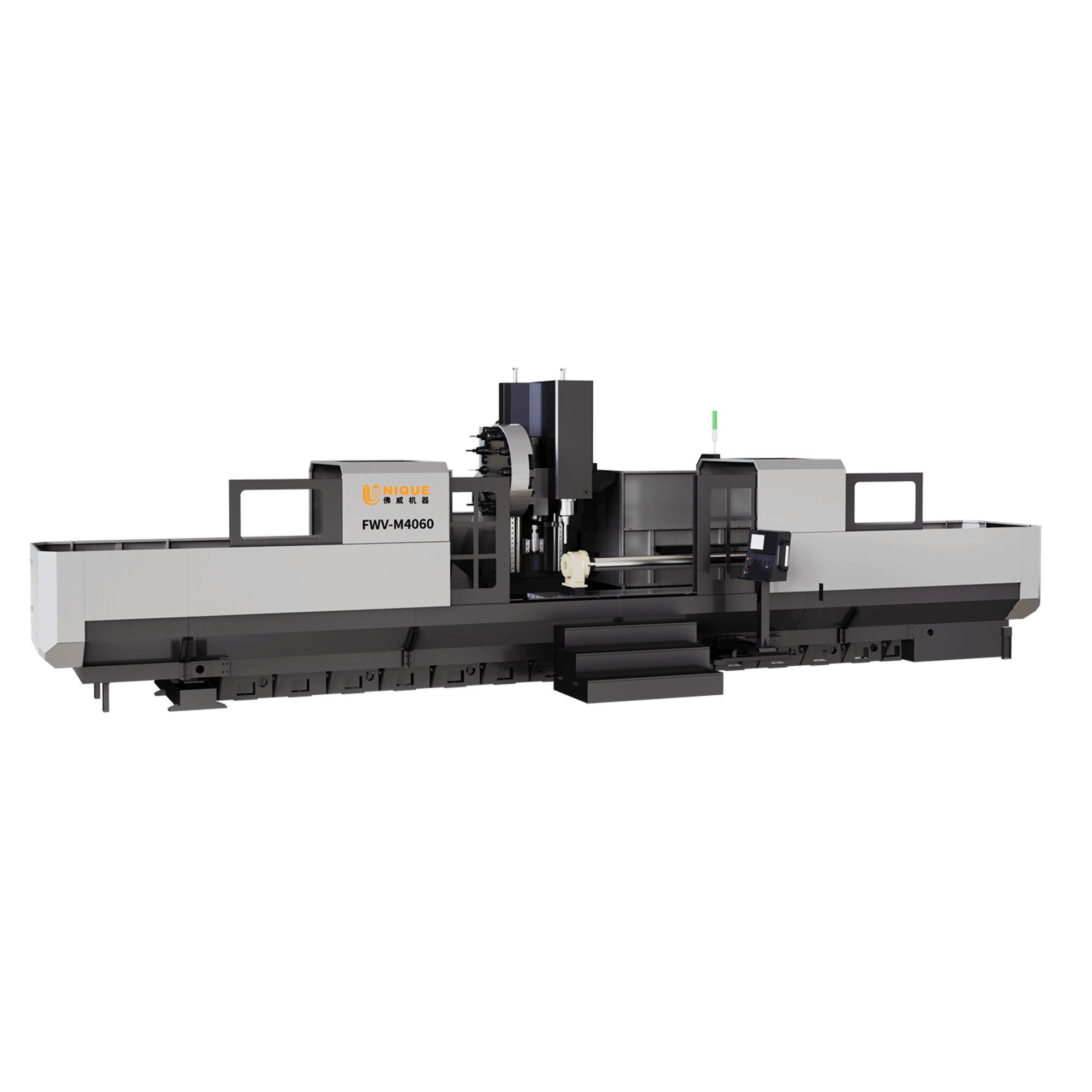

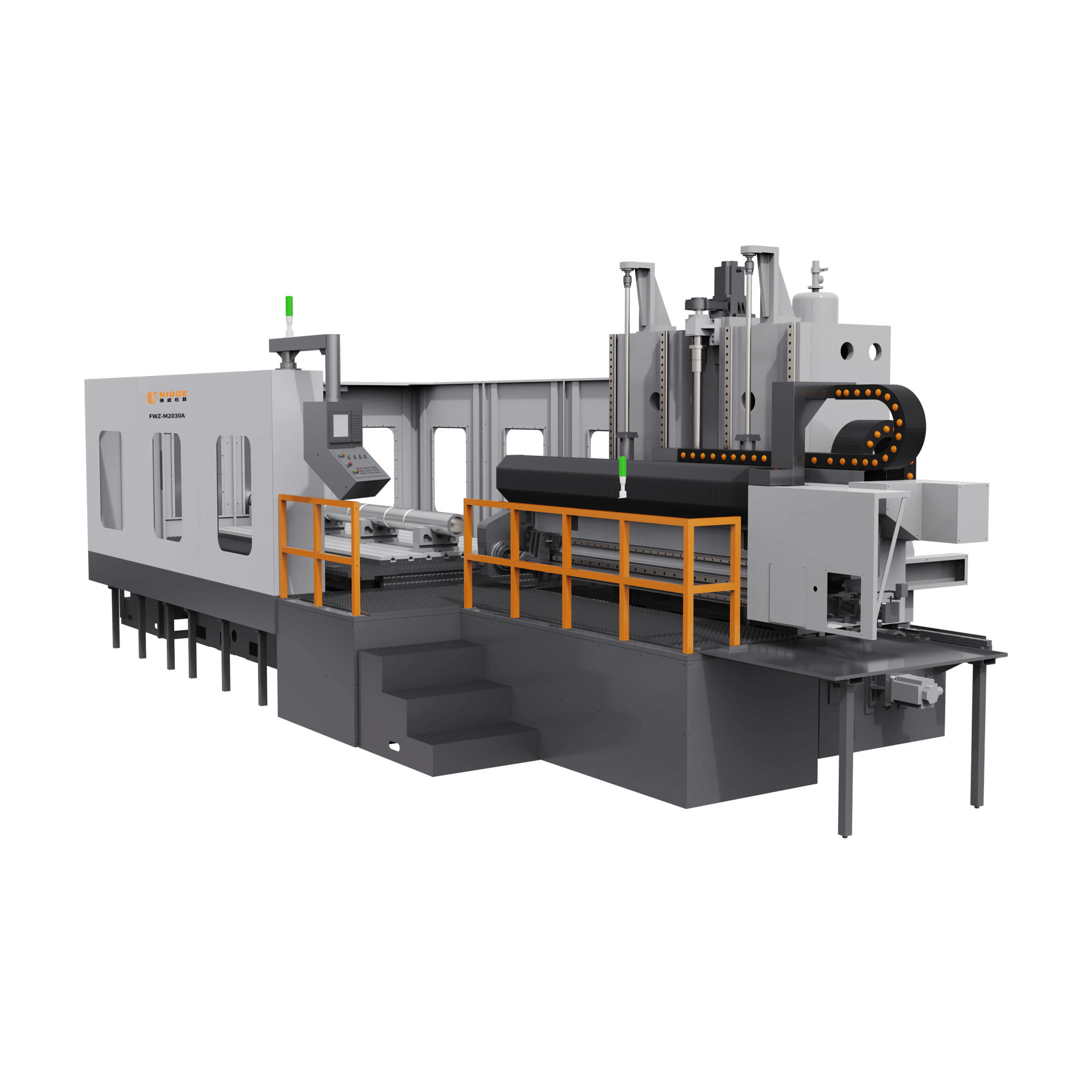

WELLTECH is equipped with more than 200 sets of large-scale precision numerical control equipments, with 40+ key process independent machining capacity, realizing high efficiency and high quality production. The company has built a digital assembly production line for “Xuanji” system (Rotary Steerable & LWD System), which has modularized integration capability of large-scale precision equipments.

Equipment assembly

The assembly workshop of WELLTECH covers an area of nearly 7,500 square meters, with five production areas:the rotary guidance production area, the drilling instrument production area, the high-speed drilling production area, the drilling induction instrument production area, and the electronic welding and assembly area, and equipped with 300㎡ of class 10,000 dust-free workshop and 200㎡ cleaning room, and realizes the whole process record from incoming materials, assembly, inspection, warehousing, and delivery, with the strong parallel operation capability of the production line, which can simultaneously carry out mechanical assembly and electronic assembly of multiple types of products.

Quality Control

WELLTECH implements full-process quality traceability, the company has passed API and ISO dual system certification, and established a perfect quality management system.

Maintenance Services

WELLTECH provides T4-level maintenance capabilities.

Collaboration process

Shorten errors with technology and fulfill promises with precision

Let precision manufacturing understand you better - one click quotation, unlock efficient production password

Get a quote now