-

Home

- Technology

- Precision manufacturing process

- Slender Shaft Processing

Industry challenges

Creating a new benchmark for precision manufacturing with exquisite

craftsmanship and innovative technology

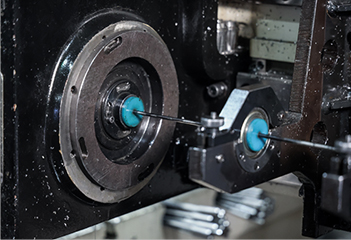

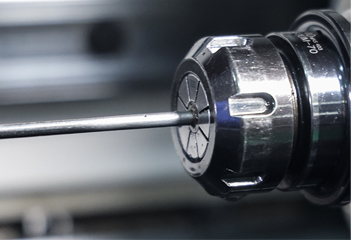

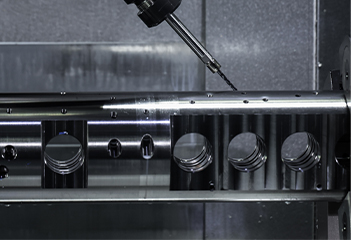

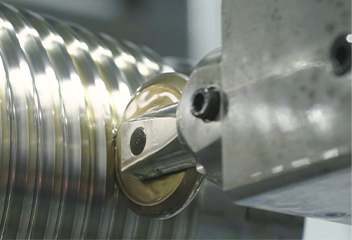

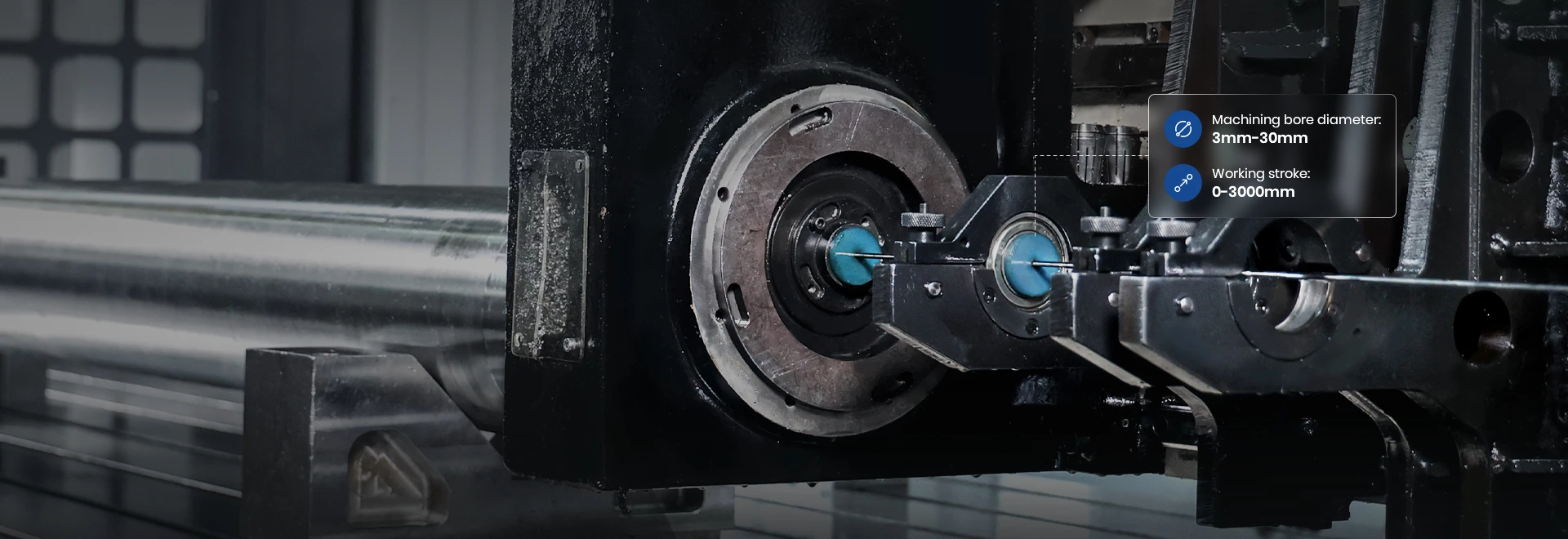

Slender Shaft Processing

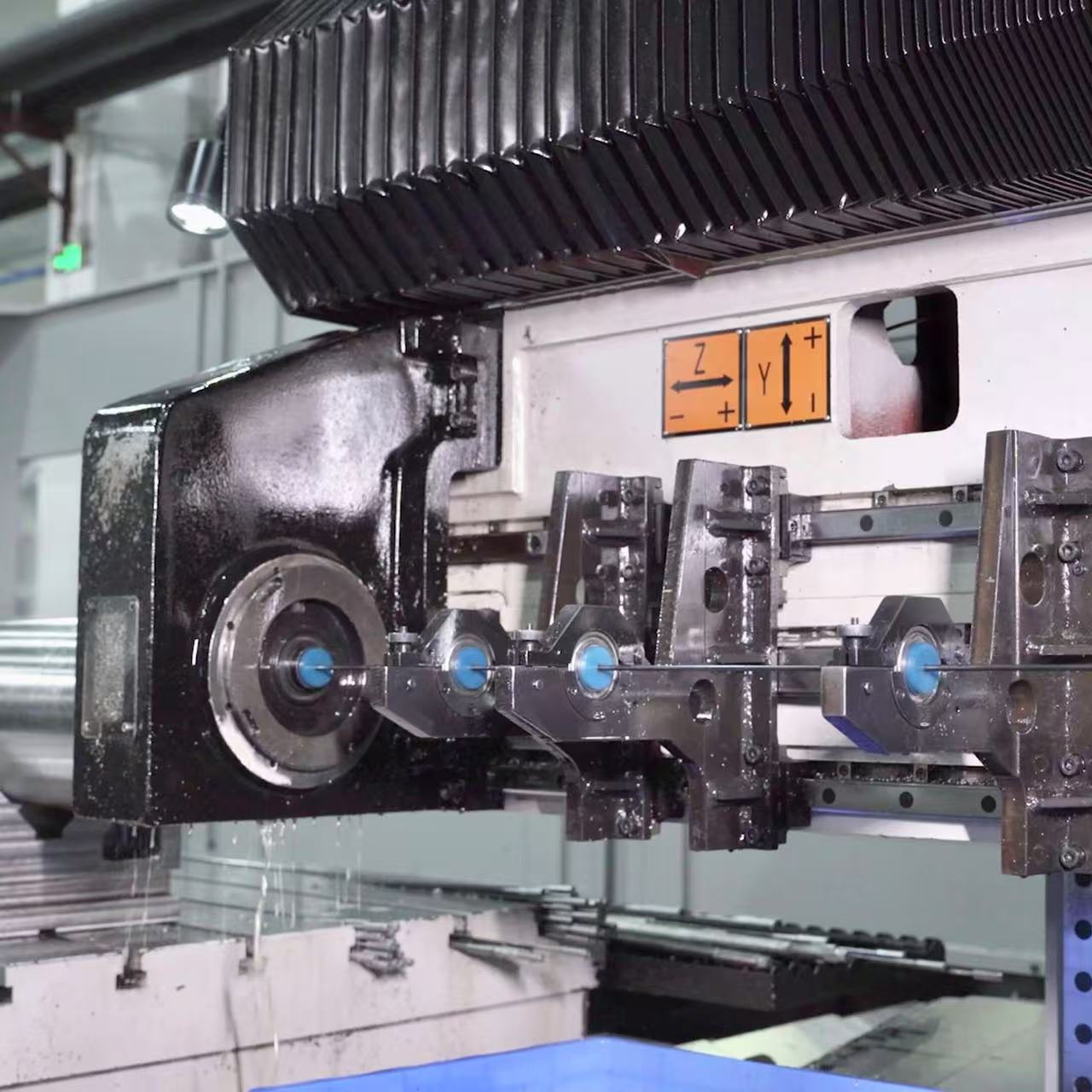

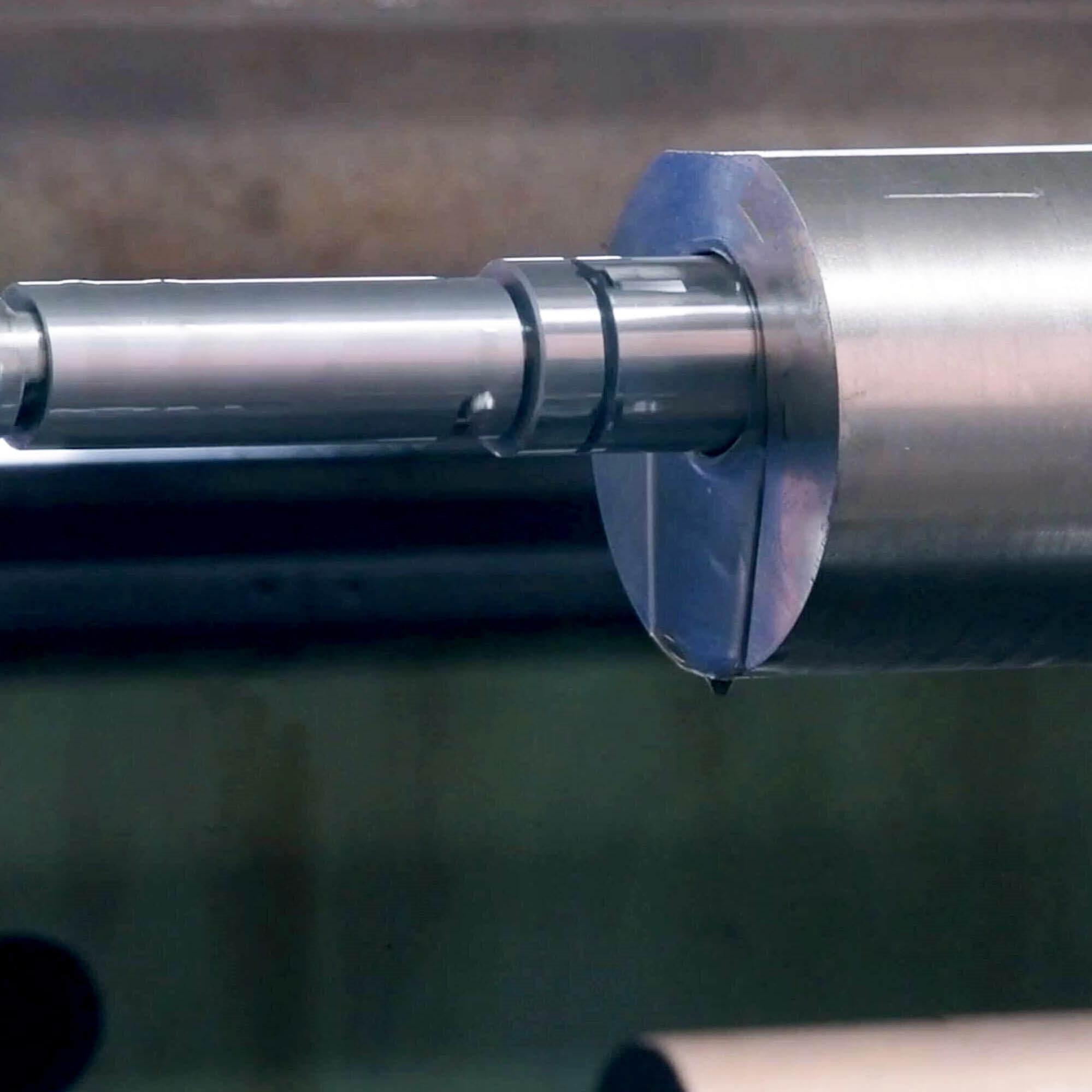

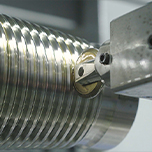

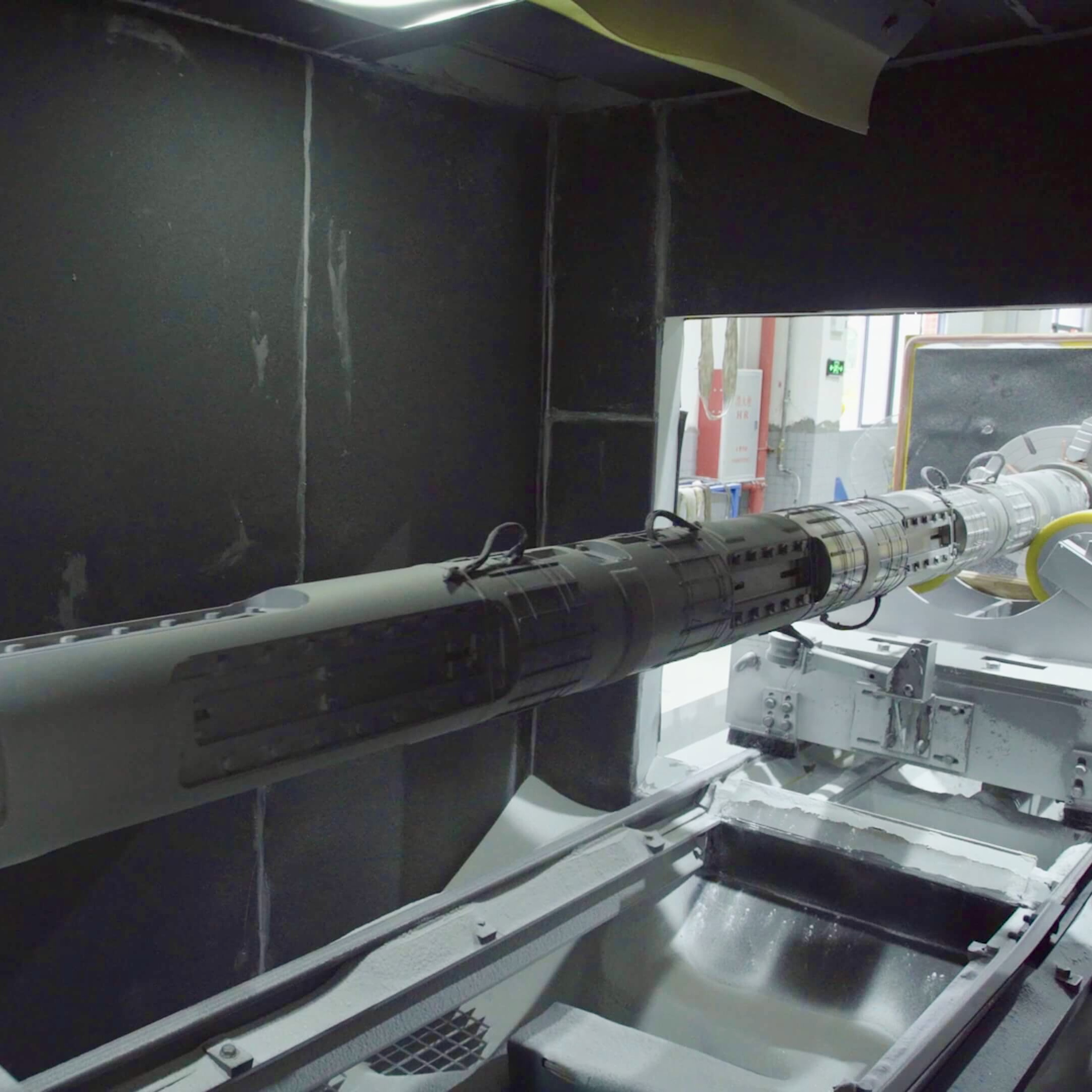

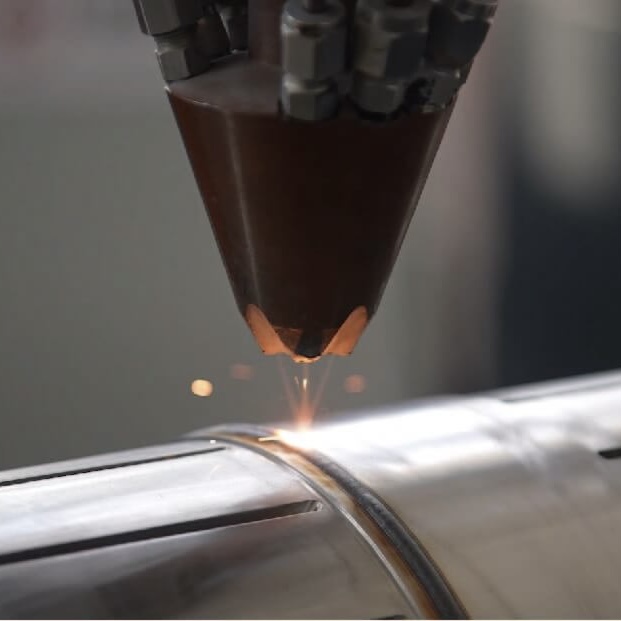

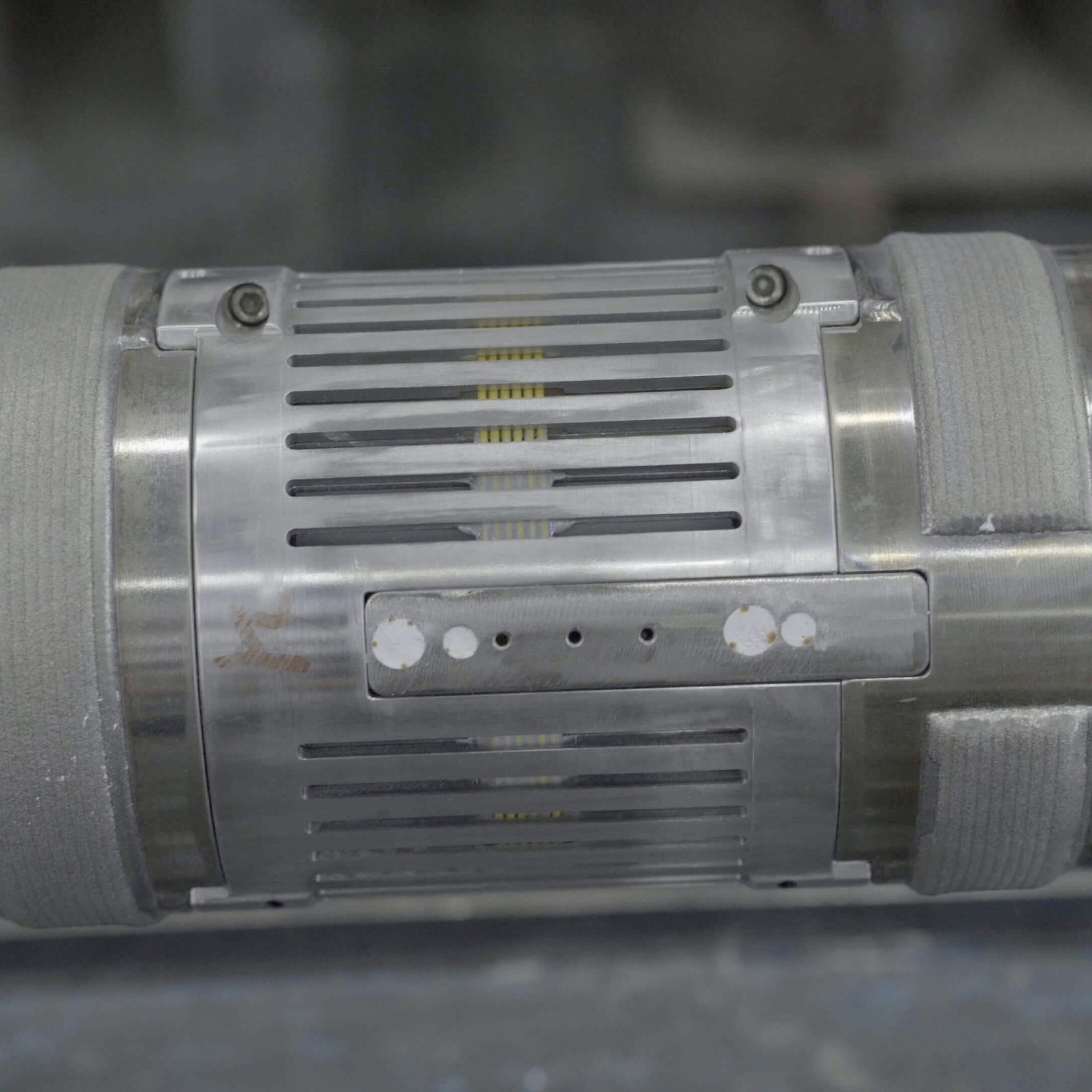

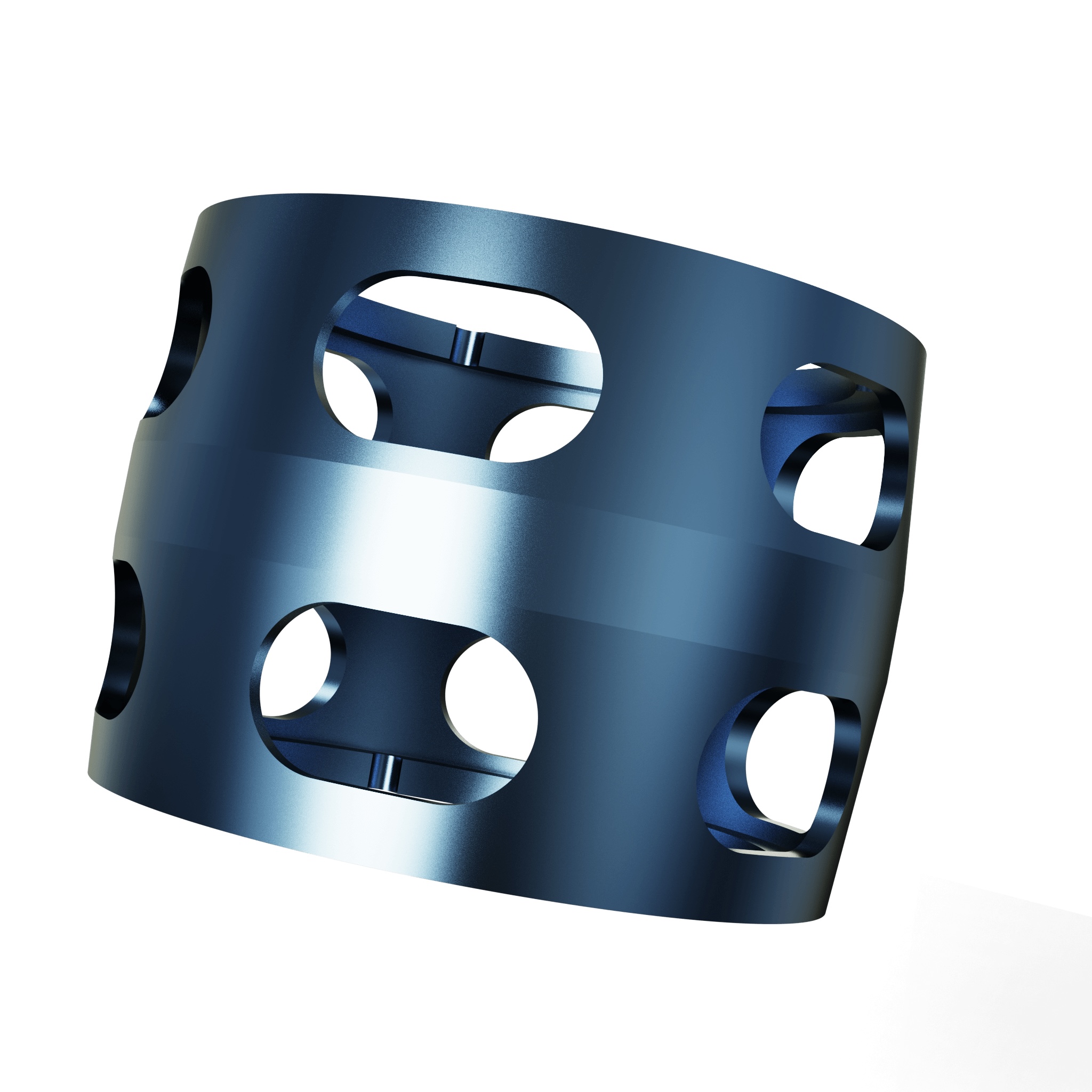

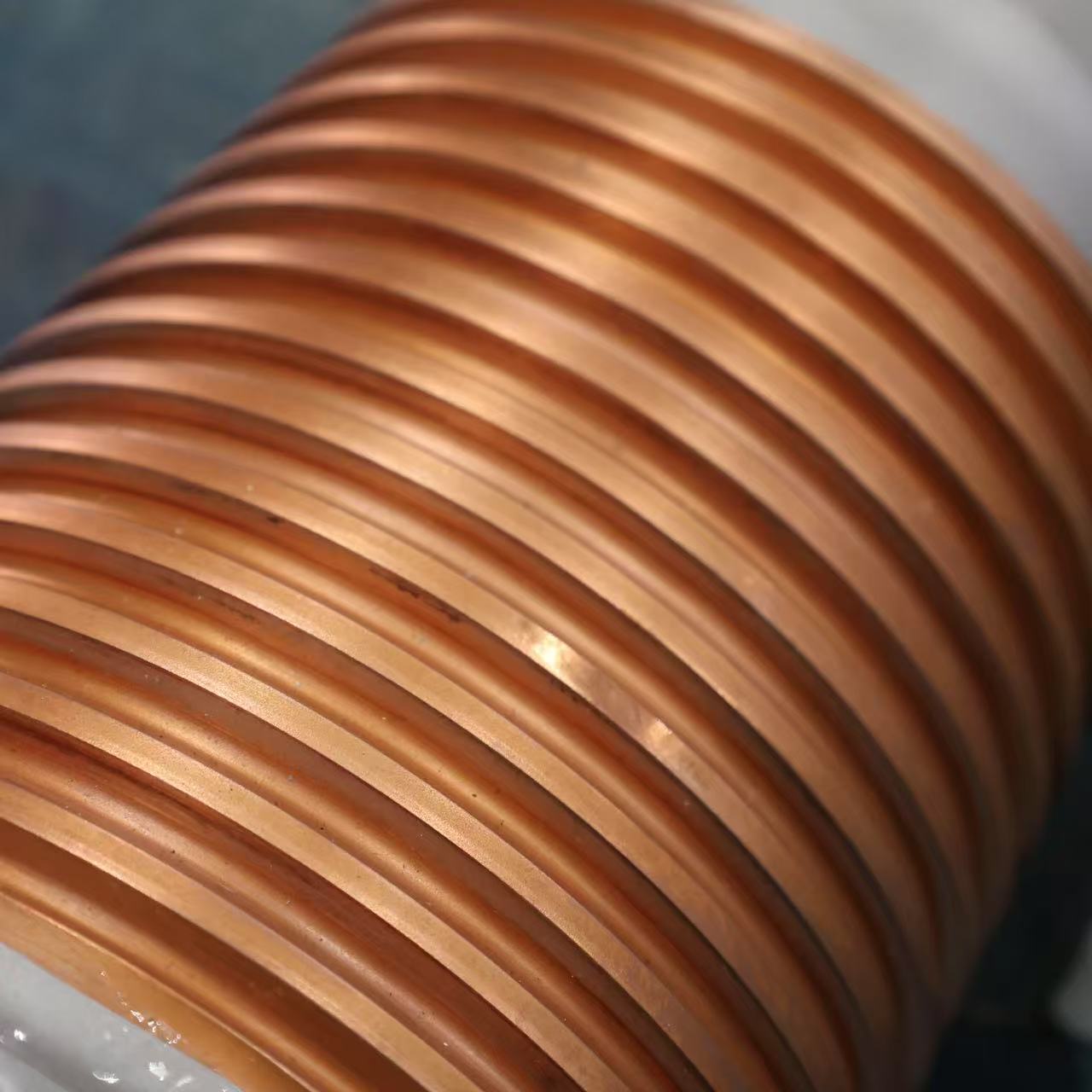

Bar stock with a length to diameter ratio of more than 20 is known as slender shaft. Due to its large aspect ratio and poor rigidity, it is highly susceptible to deformation by cutting force and cutting heat during processing, which brings great challenges to the machining. However, WELLTECH, with its outstanding technical strength and innovative spirit, has successfully overcome the problems of unstable machining quality, high machining cost and low efficiency by deeply optimizing the geometric parameters of the tool and the technological scheme, and by adopting specially designed special jigs and fixtures. It has achieved the processing of workpieces with a maximum length of 4500mm, a diameter of Φ55, a material removal of up to 50%, and workpieces with complex cavities, with straightness up to 0.2, and both the shape and position accuracy and dimensional accuracy meet the product quality requirements.

Craft Case Gallery

Explore all gallery

Why us

Explore more

The Industrial Pilot Testing Service Capability

We achieve full-chain integration of prototype production, equipment assembly and intelligent maintenance to ensure full-cycle accurate delivery.

Scale Production

WELLTECH's modern production workshops, standardized process flow and efficient capacity layout enable scale production to meet customer needs with stable quality and batch delivery capability.

Shorten errors with technology and fulfill promises with precision

Let precision manufacturing understand you better - one click quotation, unlock efficient production password

Get a quote now