-

Home

- Technology

- Special arts and crafts

- Thread Copper Plating

Industry challenges

Creating a new benchmark for precision manufacturing with exquisite

craftsmanship and innovative technology

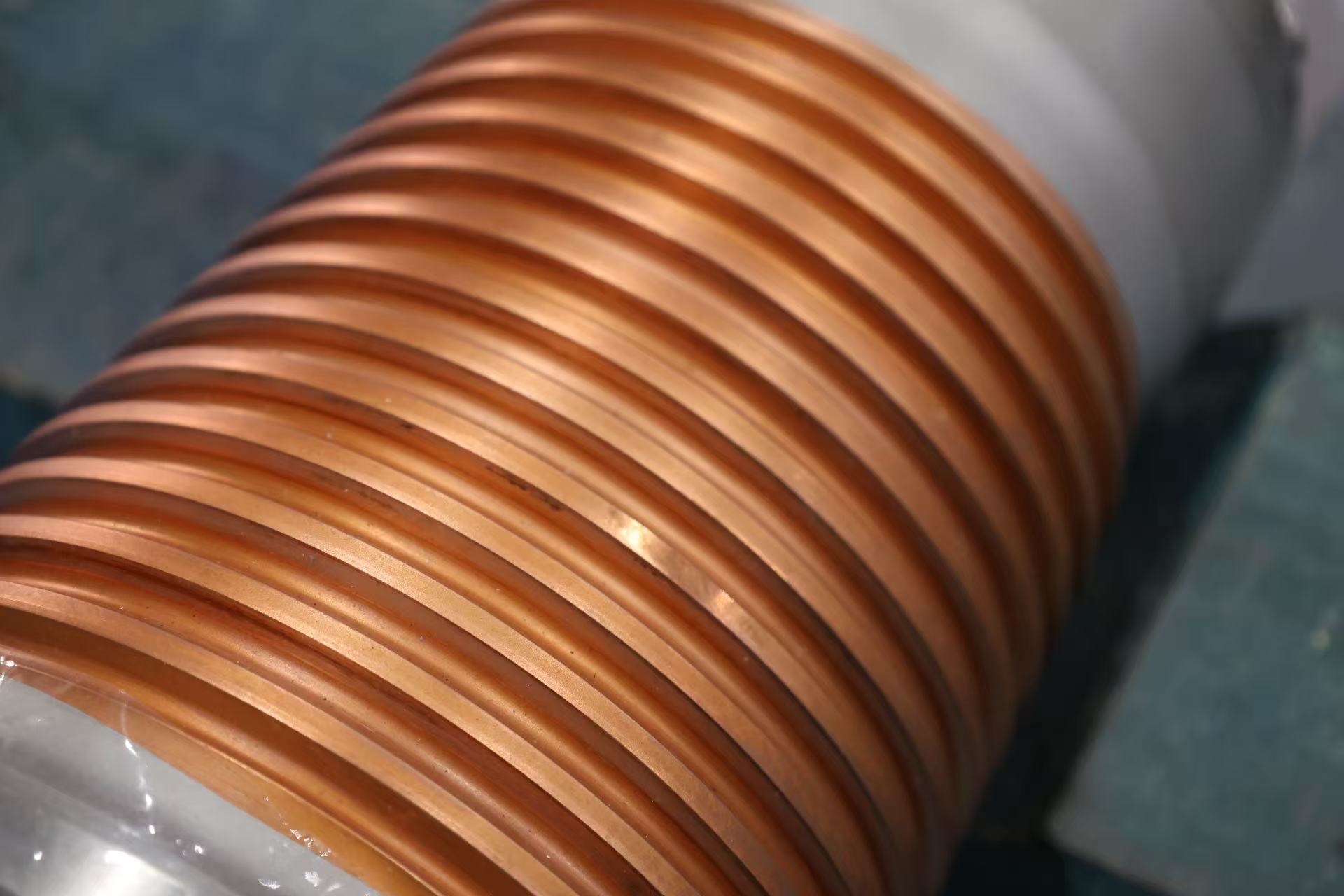

Thread Copper Plating

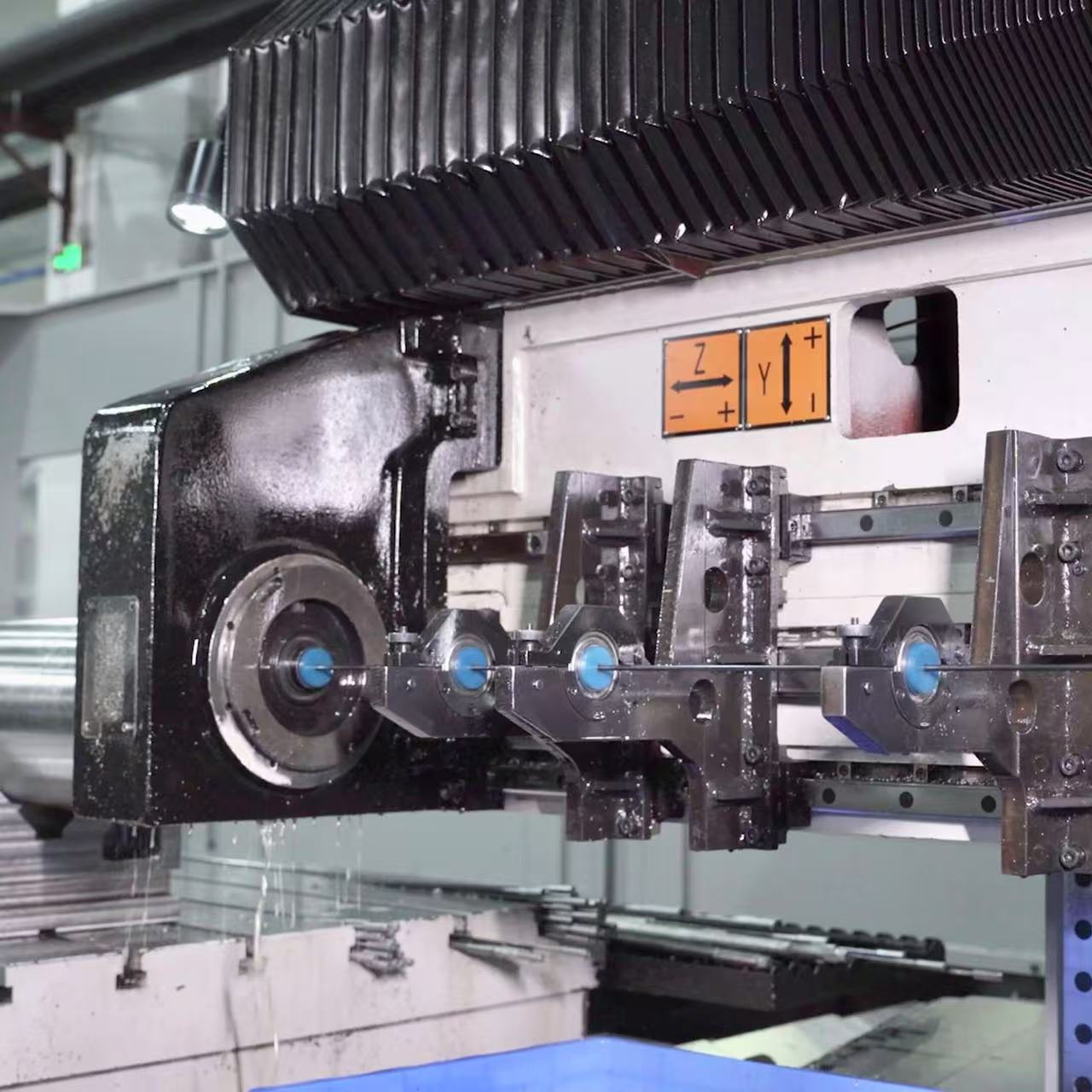

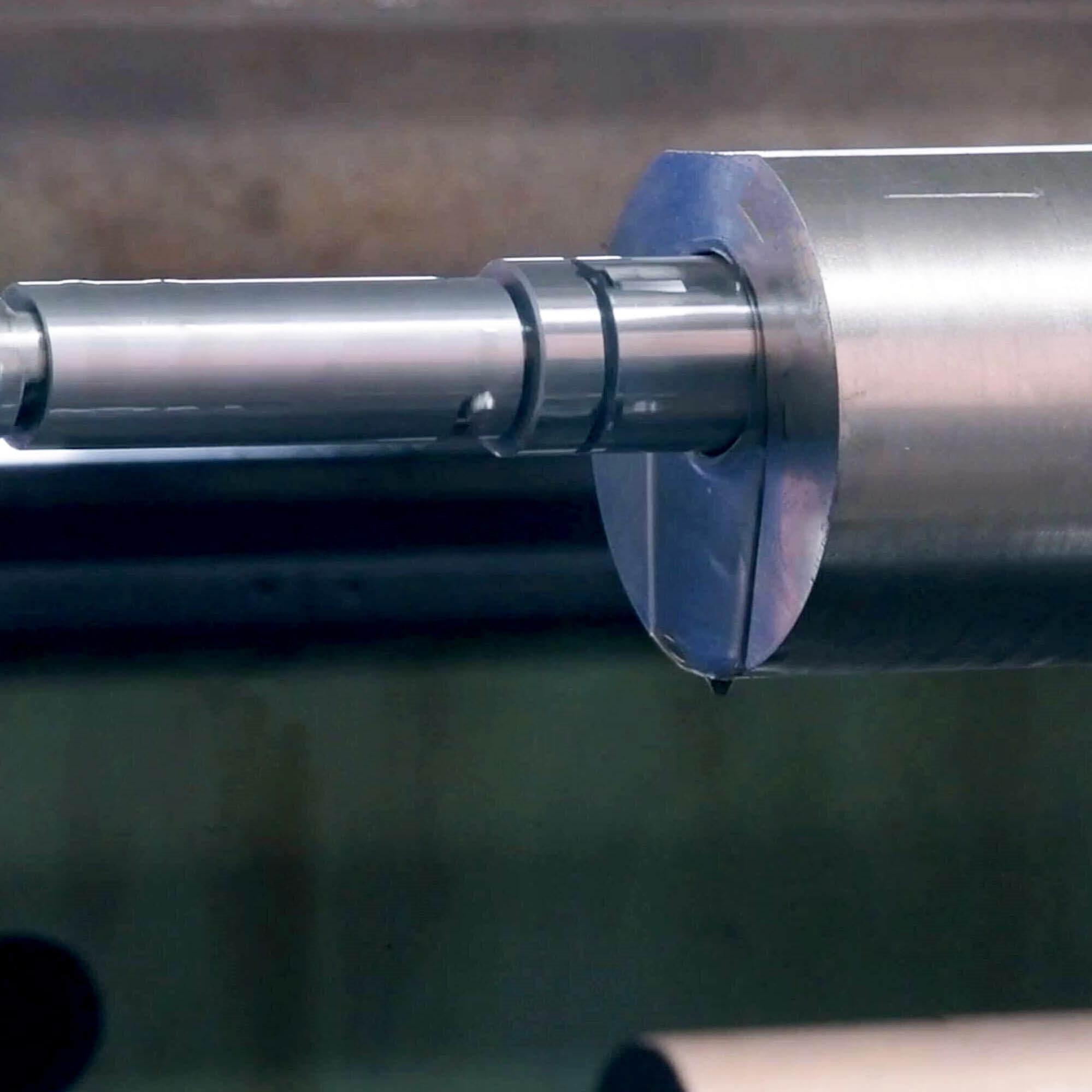

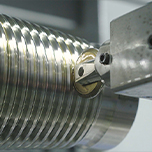

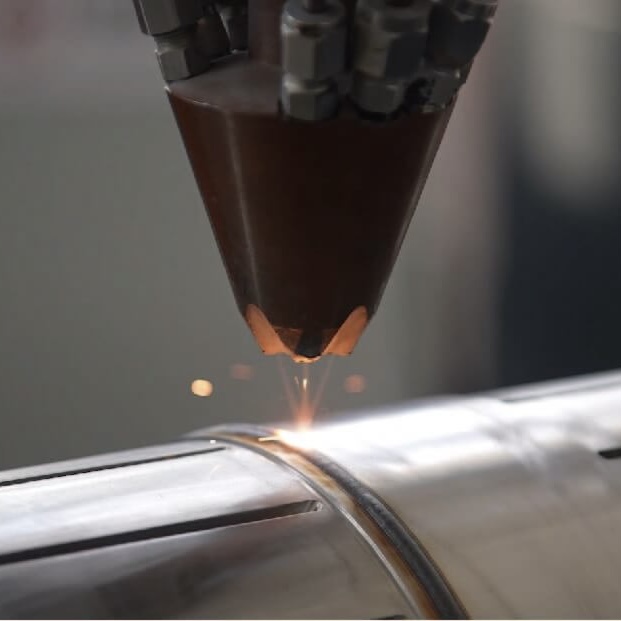

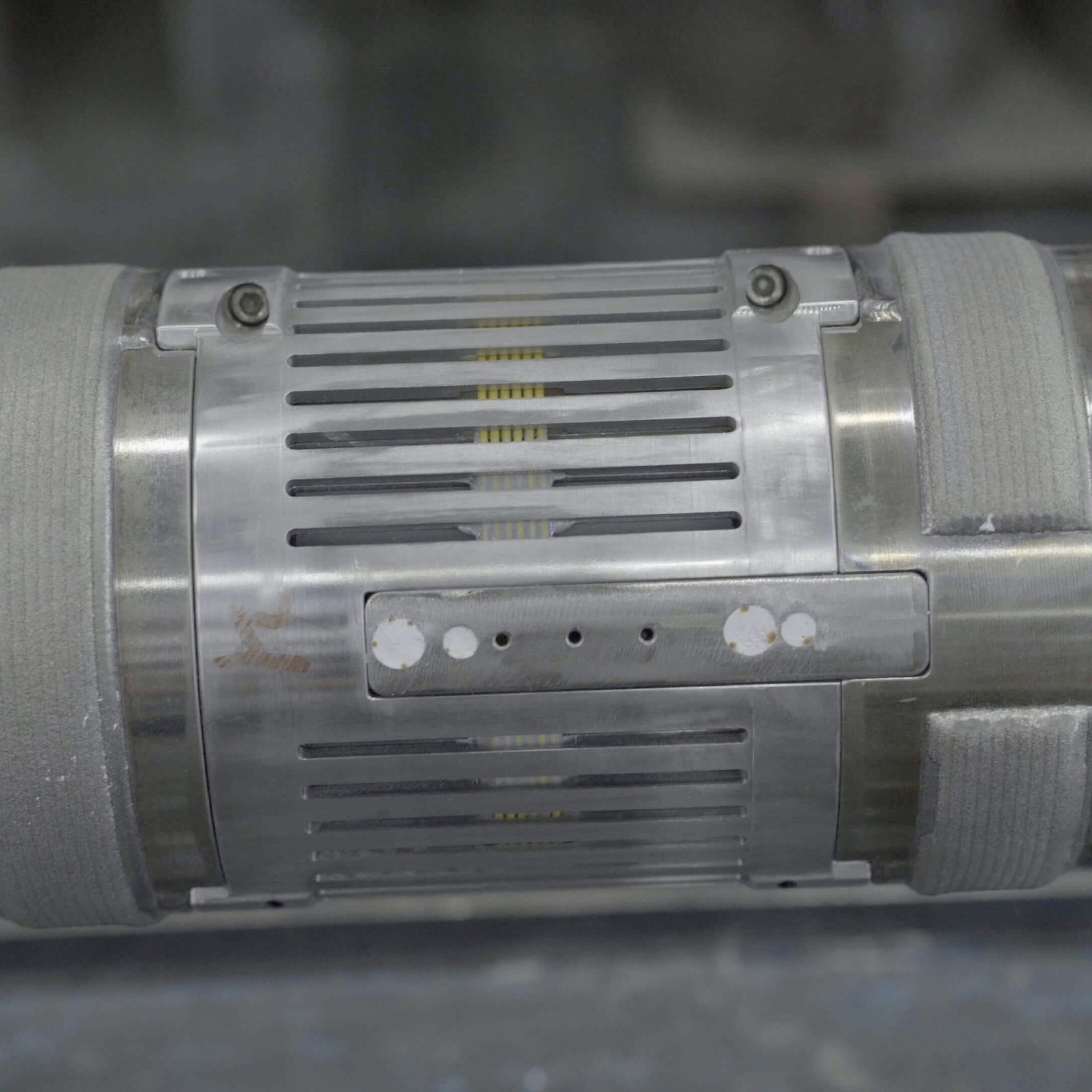

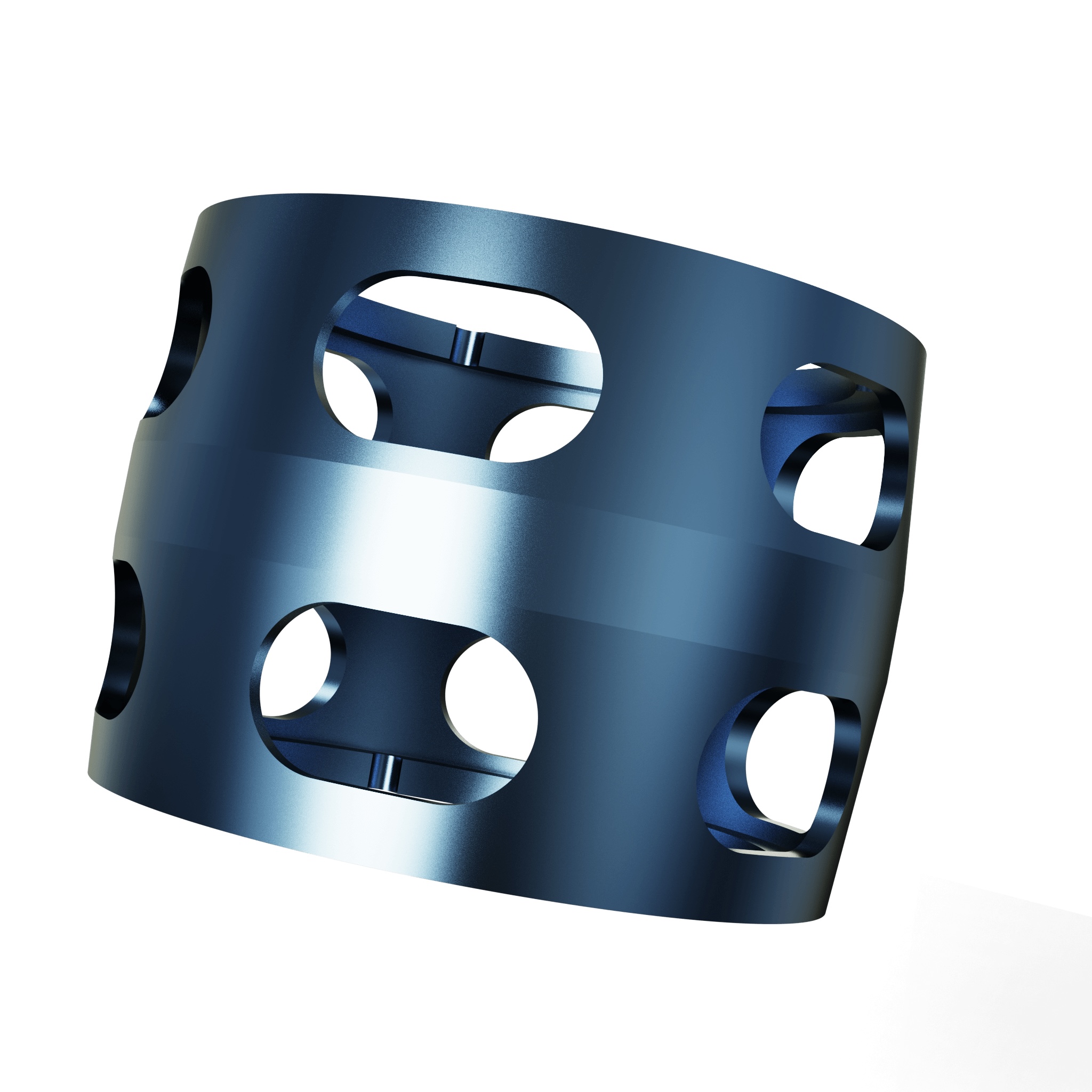

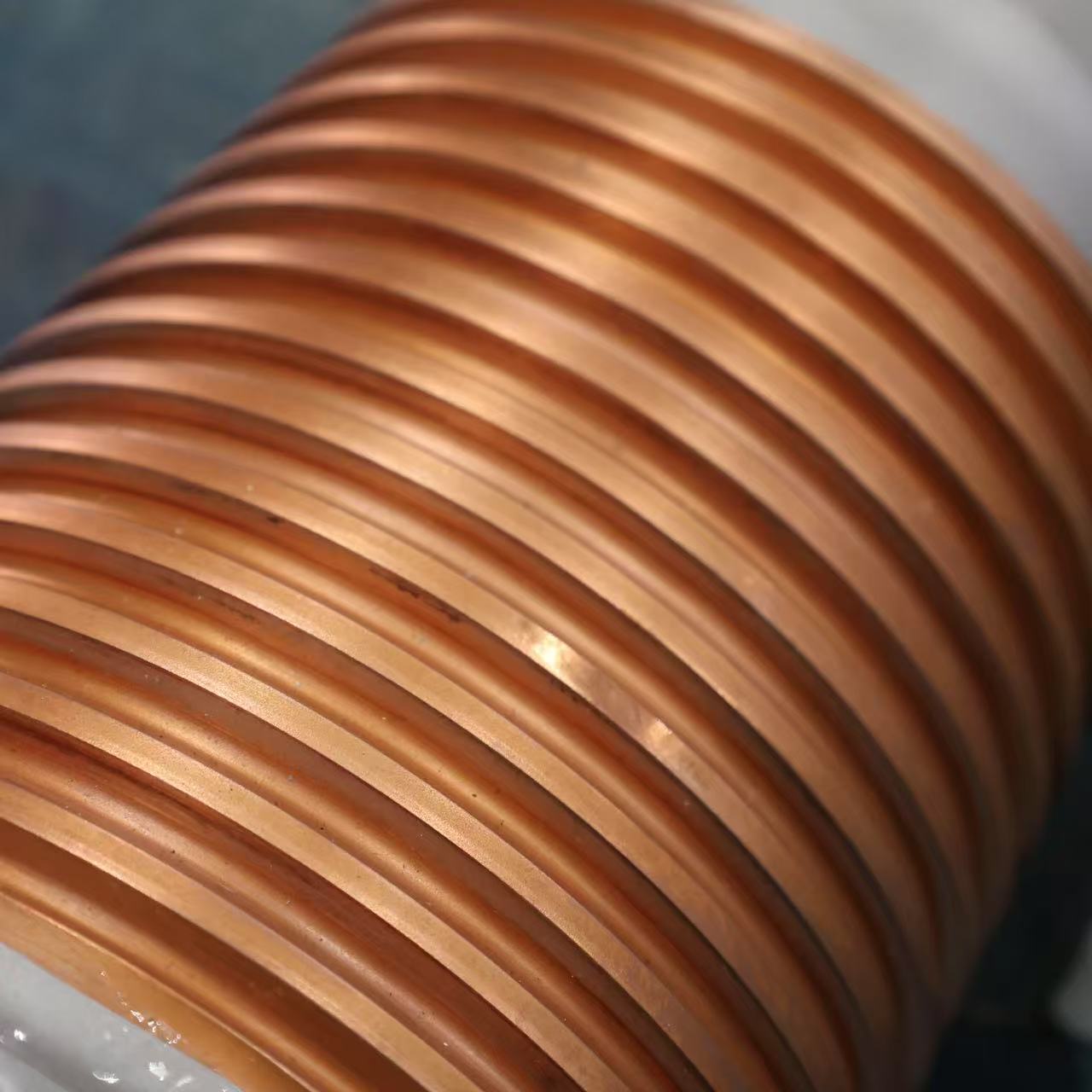

In electroplating, the electrolytic principle is utilized to form a uniform, dense, and well-bonded copper film on the surface of drilling tools and instruments' connecting threads (including complete and incomplete threads) in order to prevent the threads from sticking to each other. WELLTECH currently has the capability of copper plating on API threads and other special threads, with a copper film thickness of10-25μm, which can effectively prevent the threads from sticking.

Craft Case Gallery

Explore all gallery

Why us

Explore more

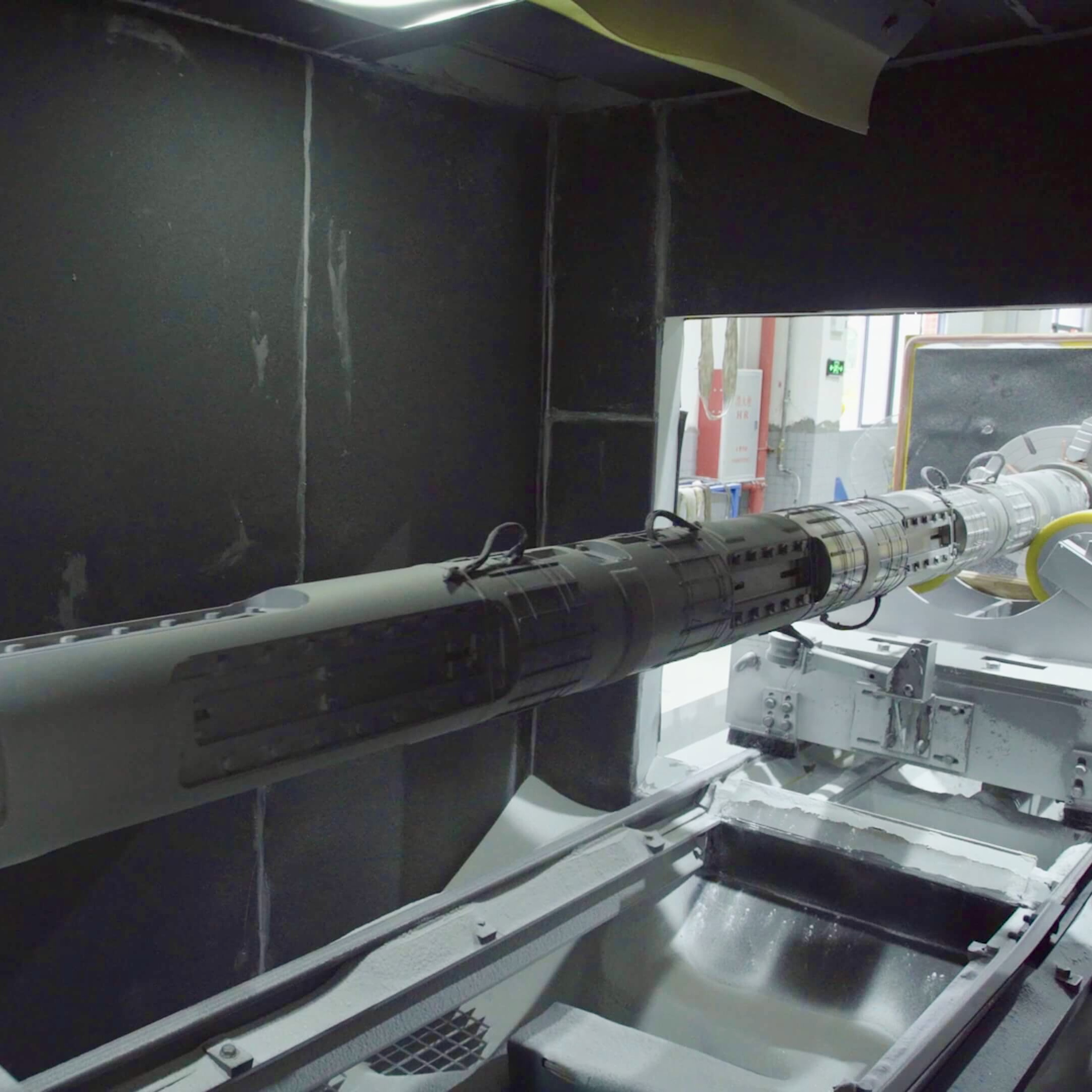

The Industrial Pilot Testing Service Capability

We achieve full-chain integration of prototype production, equipment assembly and intelligent maintenance to ensure full-cycle accurate delivery.

Scale Production

WELLTECH's modern production workshops, standardized process flow and efficient capacity layout enable scale production to meet customer needs with stable quality and batch delivery capability.

Shorten errors with technology and fulfill promises with precision

Let precision manufacturing understand you better - one click quotation, unlock efficient production password

Get a quote now