-

Home

- Technology

- Precision manufacturing process

- Precision Deep Hole Processing

Industry challenges

Creating a new benchmark for precision manufacturing with exquisite

craftsmanship and innovative technology

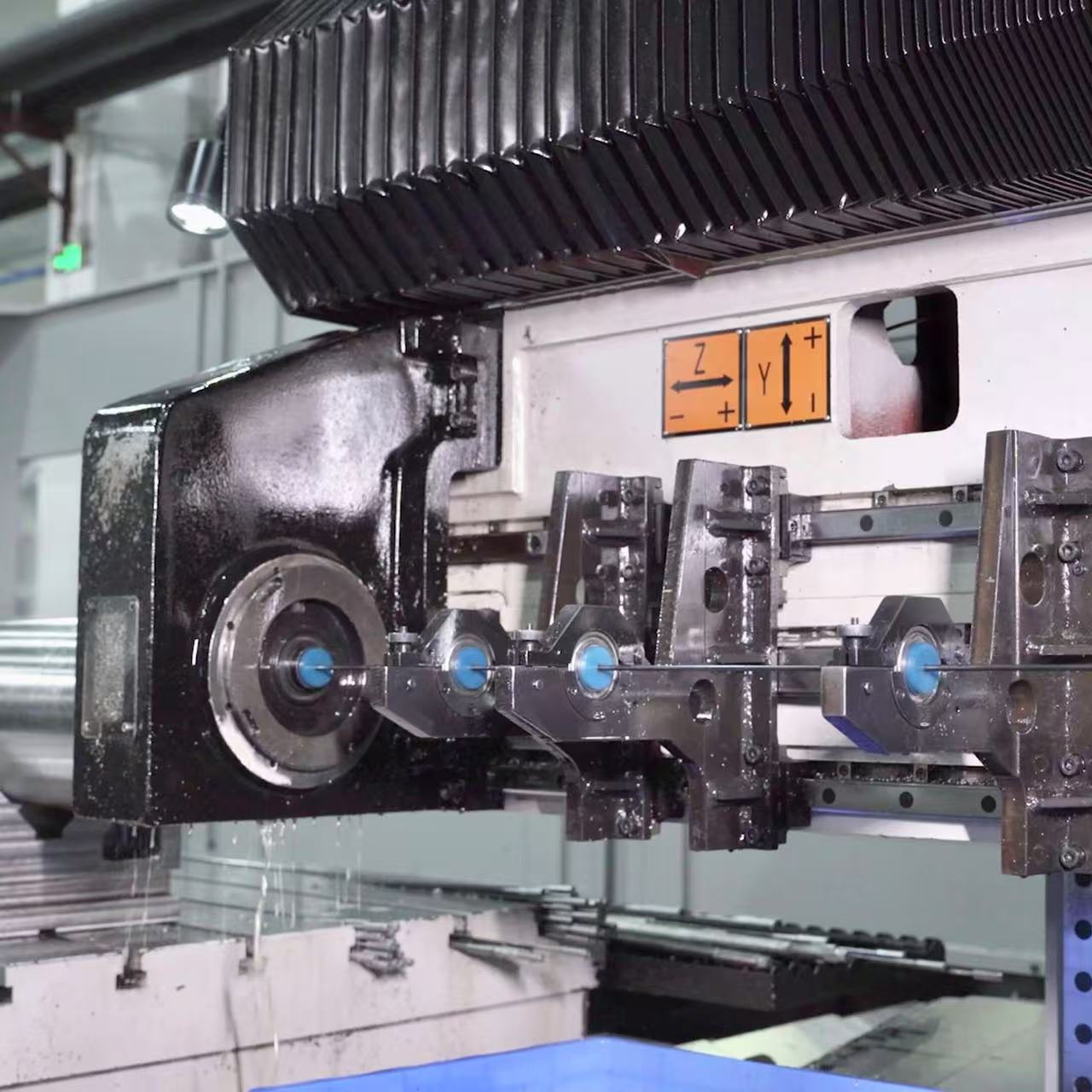

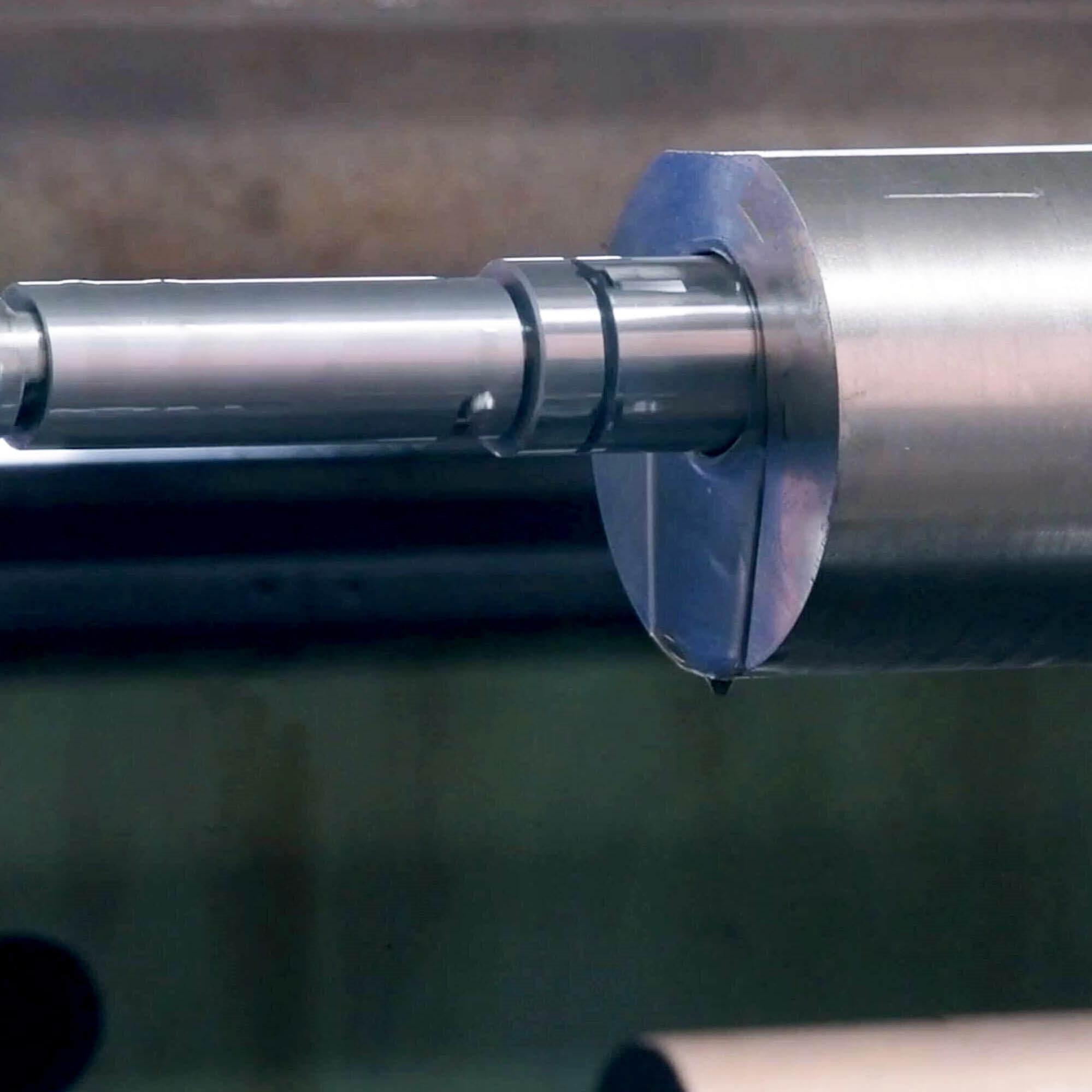

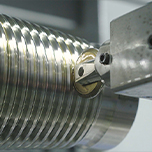

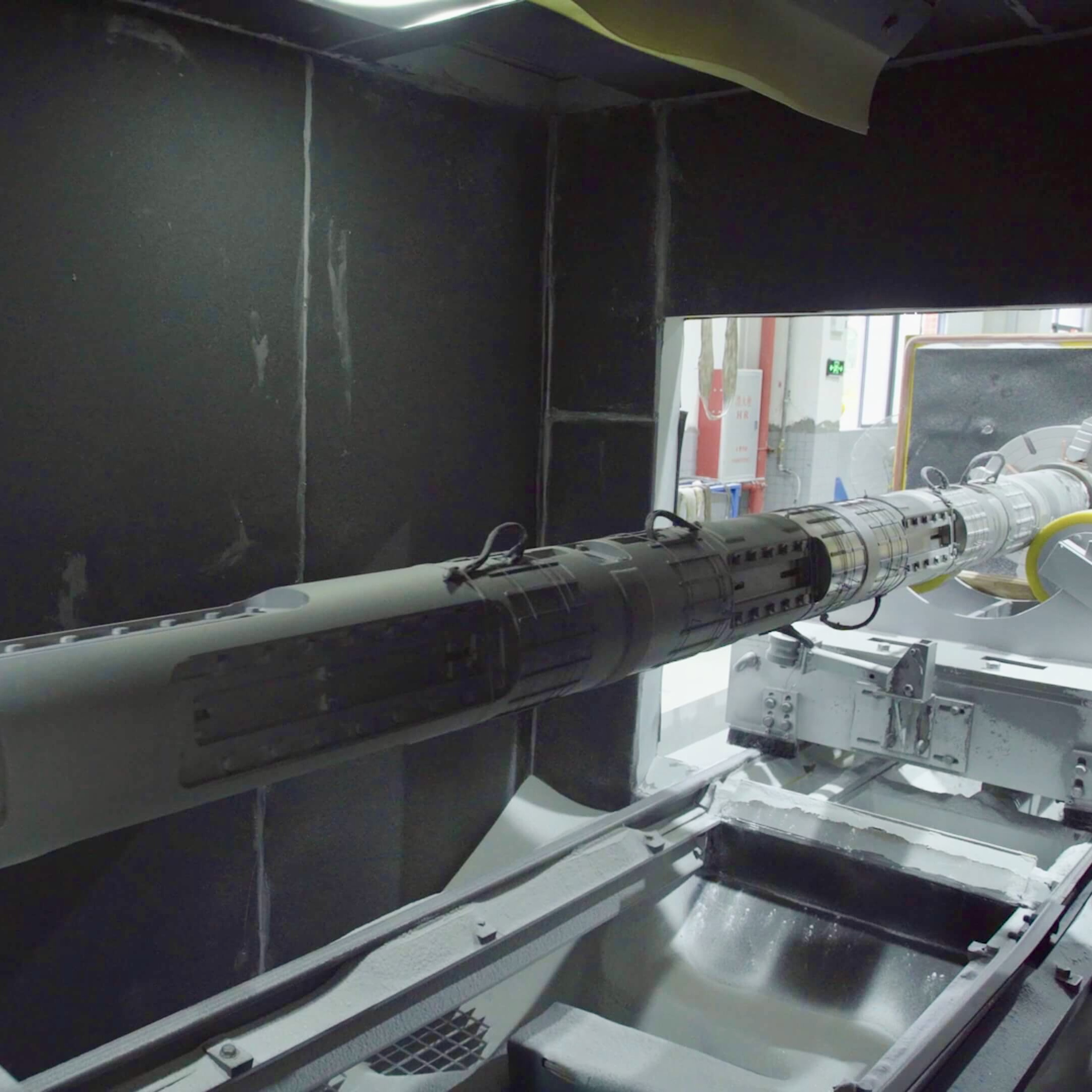

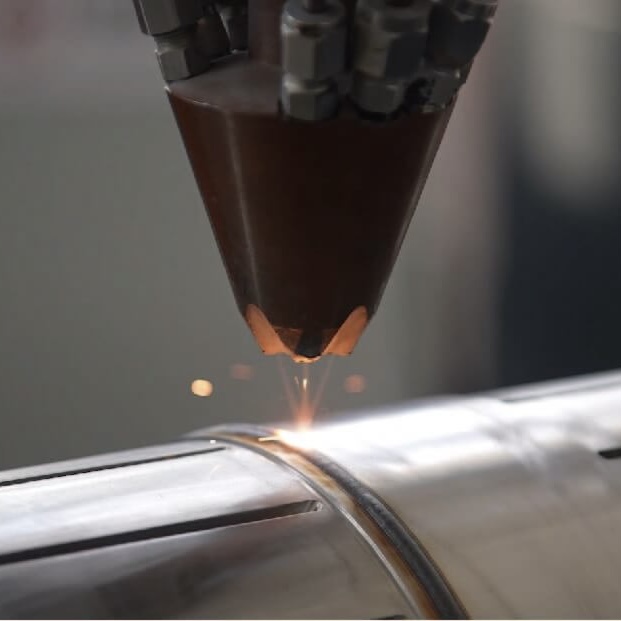

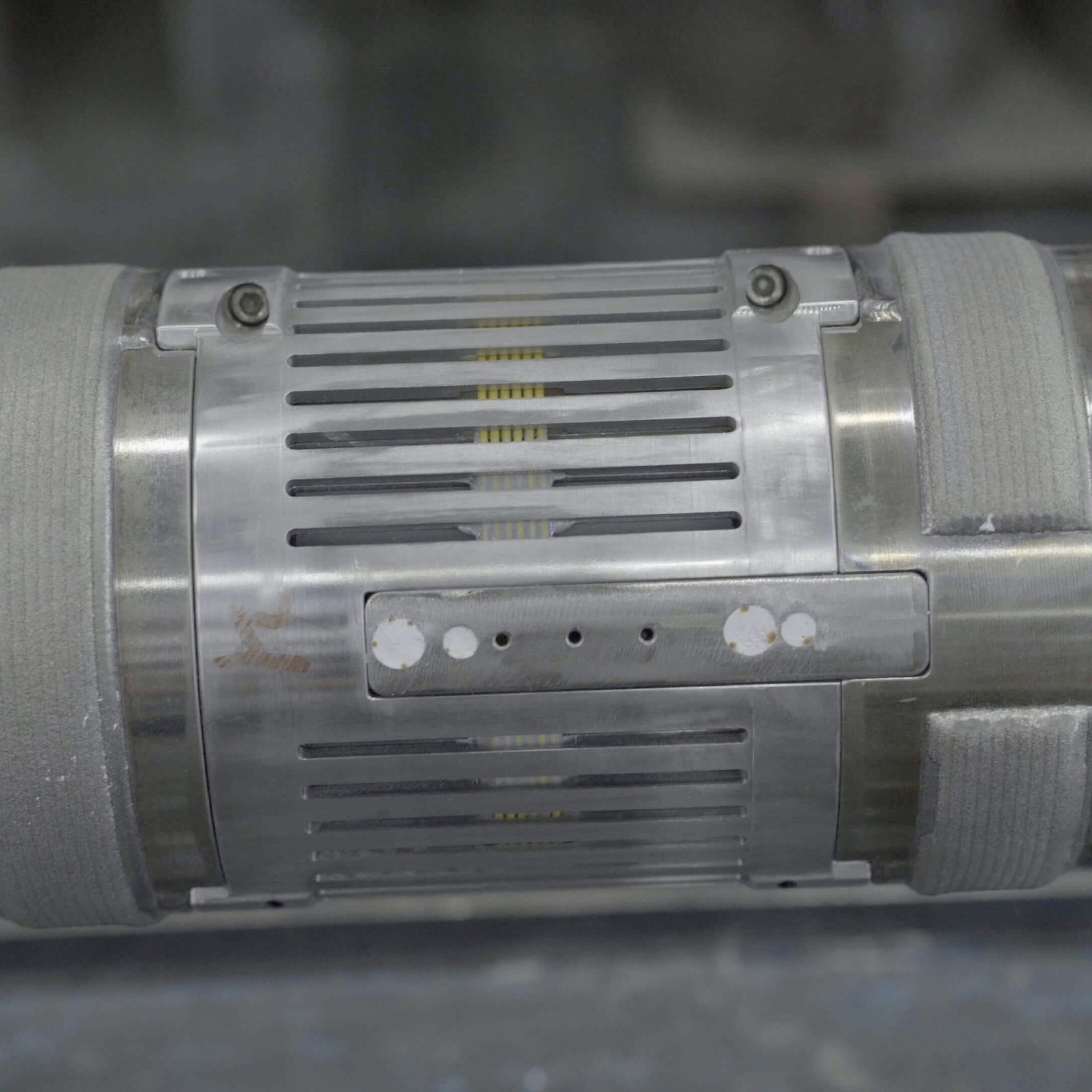

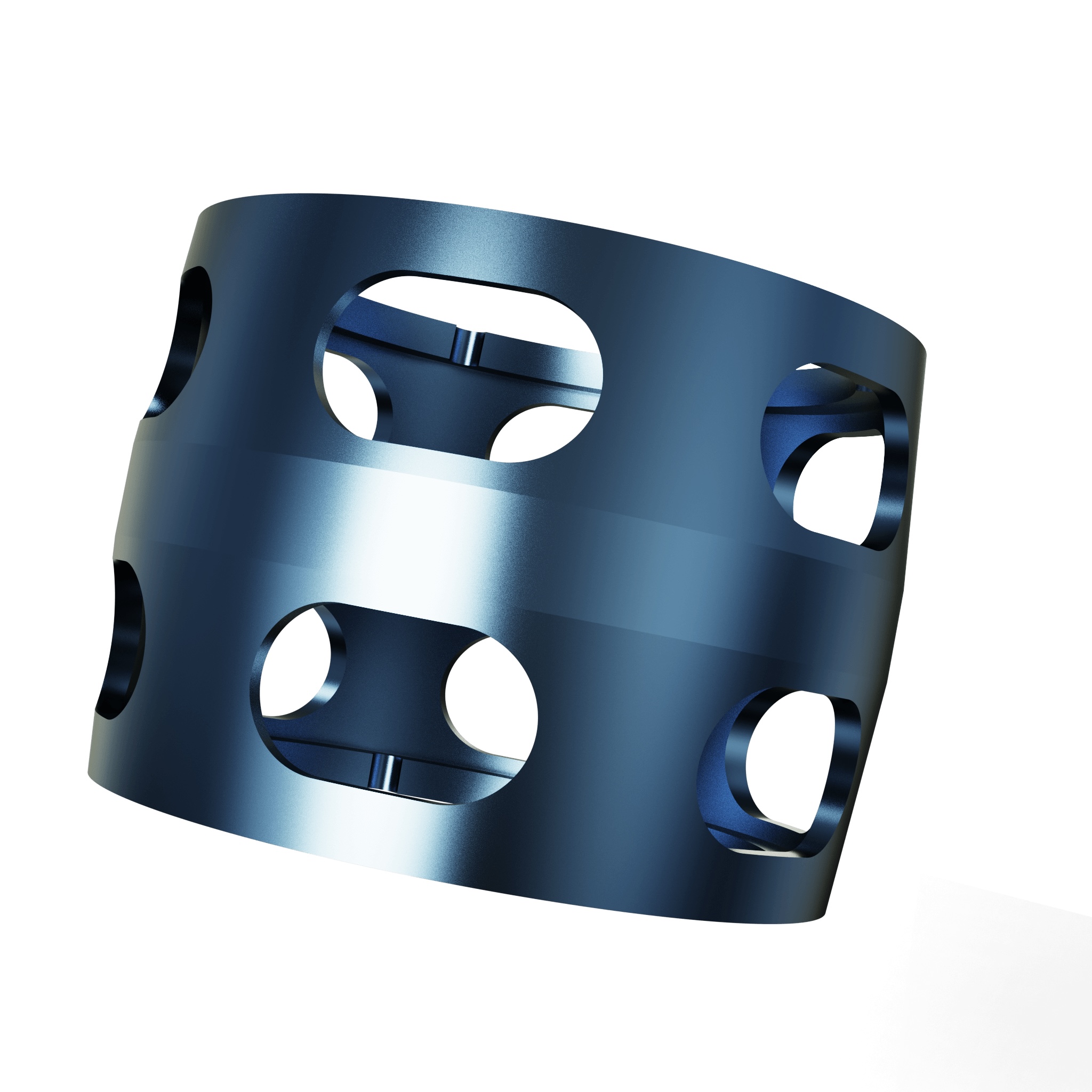

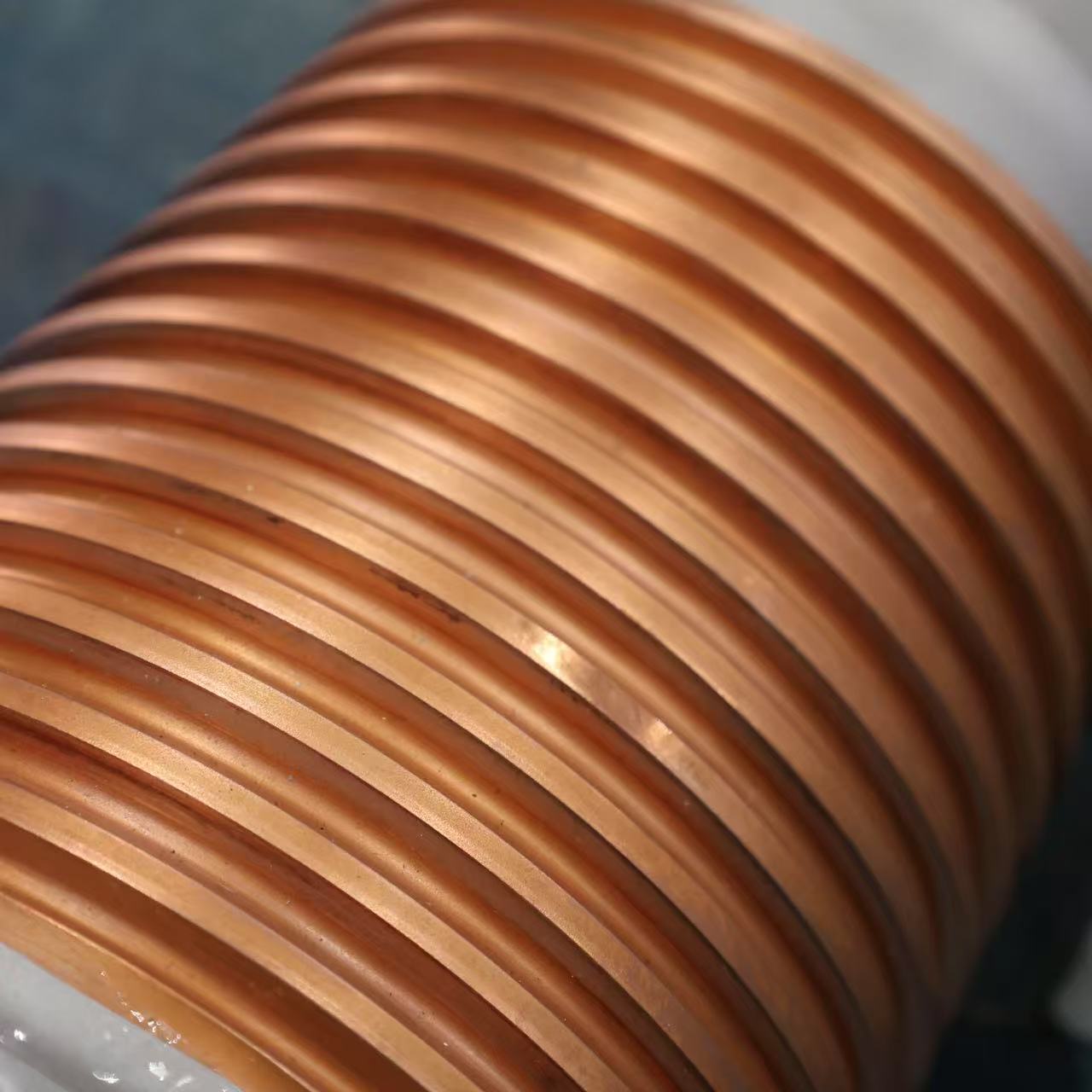

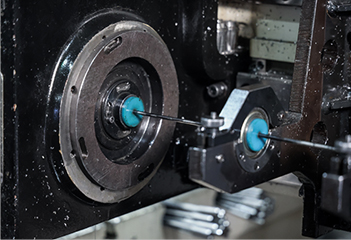

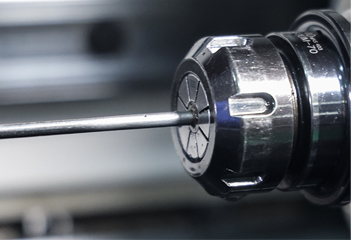

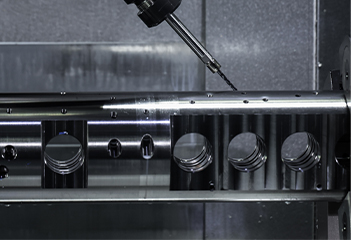

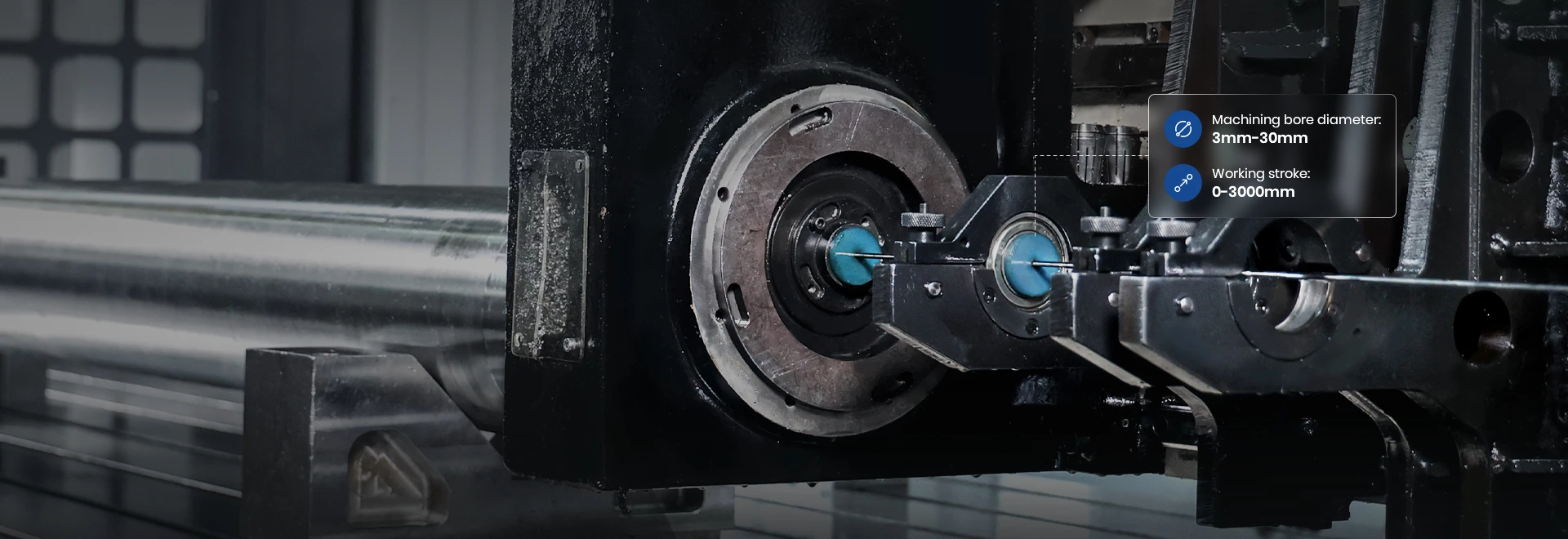

Precision Deep Hole Processing

By using customized and specialized deep hole cutting tools and deep hole machine tools, high-precision processing of difficult-to-cut materials such as high-difficulty multi-step sealed deep holes and inner ring grooves of deep holes can be achieved. The processing range of the inner hole diameter of the parts is Φ25-250 mm, the maximum processing depth is 10m, and the coaxiality of the processing hole is 0.02mm. The diameter of the inner ring groove of the deep hole can reach 1.5 times the size of the through hole, and the surface finish is better than Ra 1.6μm.

Craft Case Gallery

Explore all gallery

Why us

Explore more

The Industrial Pilot Testing Service Capability

We achieve full-chain integration of prototype production, equipment assembly and intelligent maintenance to ensure full-cycle accurate delivery.

Scale Production

WELLTECH's modern production workshops, standardized process flow and efficient capacity layout enable scale production to meet customer needs with stable quality and batch delivery capability.

Shorten errors with technology and fulfill promises with precision

Let precision manufacturing understand you better - one click quotation, unlock efficient production password

Get a quote now