-

Home

- Technology

- Precision manufacturing process

- Thread Rolling

Industry challenges

Creating a new benchmark for precision manufacturing with exquisite

craftsmanship and innovative technology

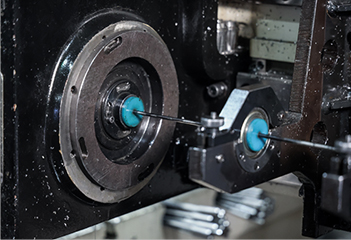

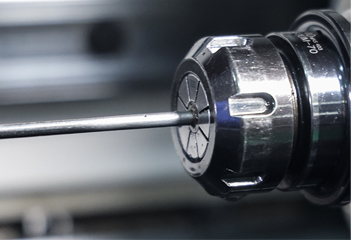

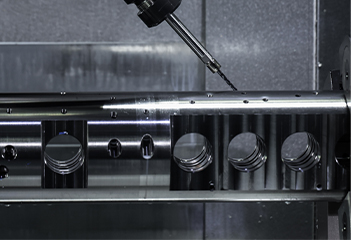

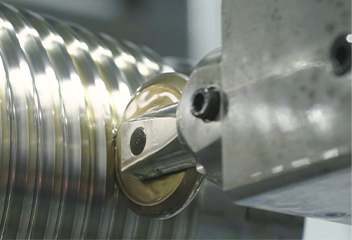

Thread Rolling

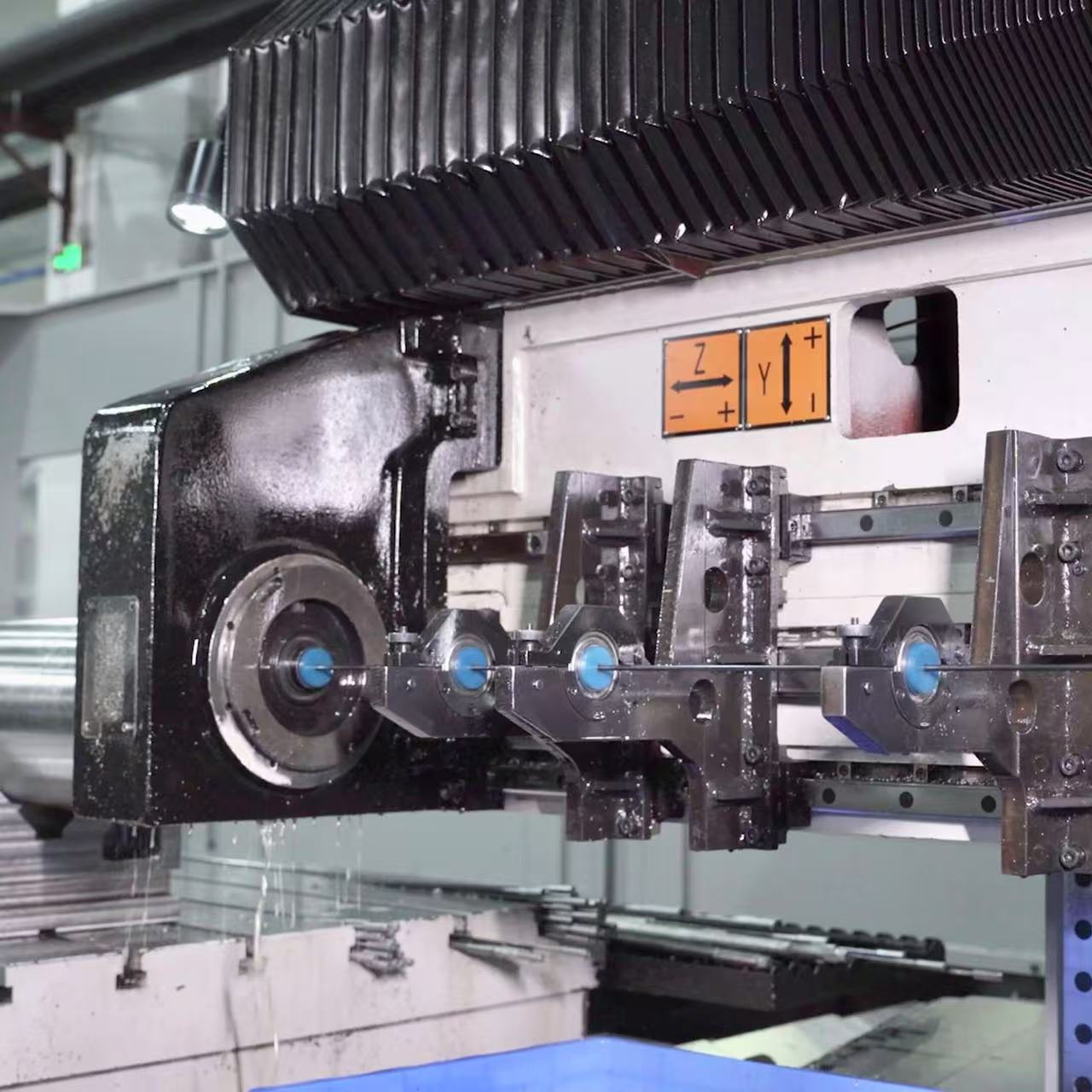

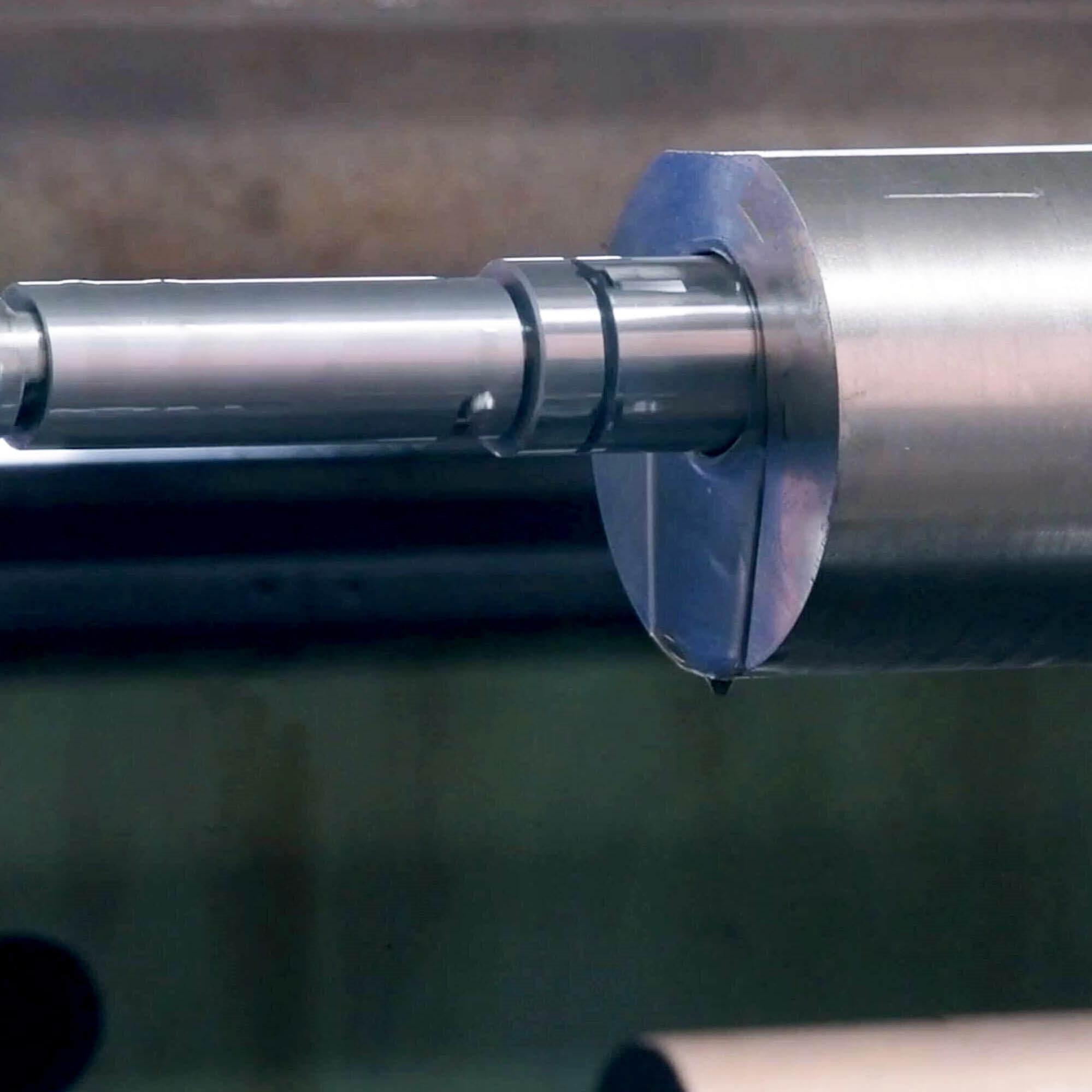

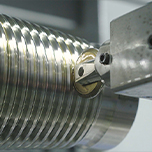

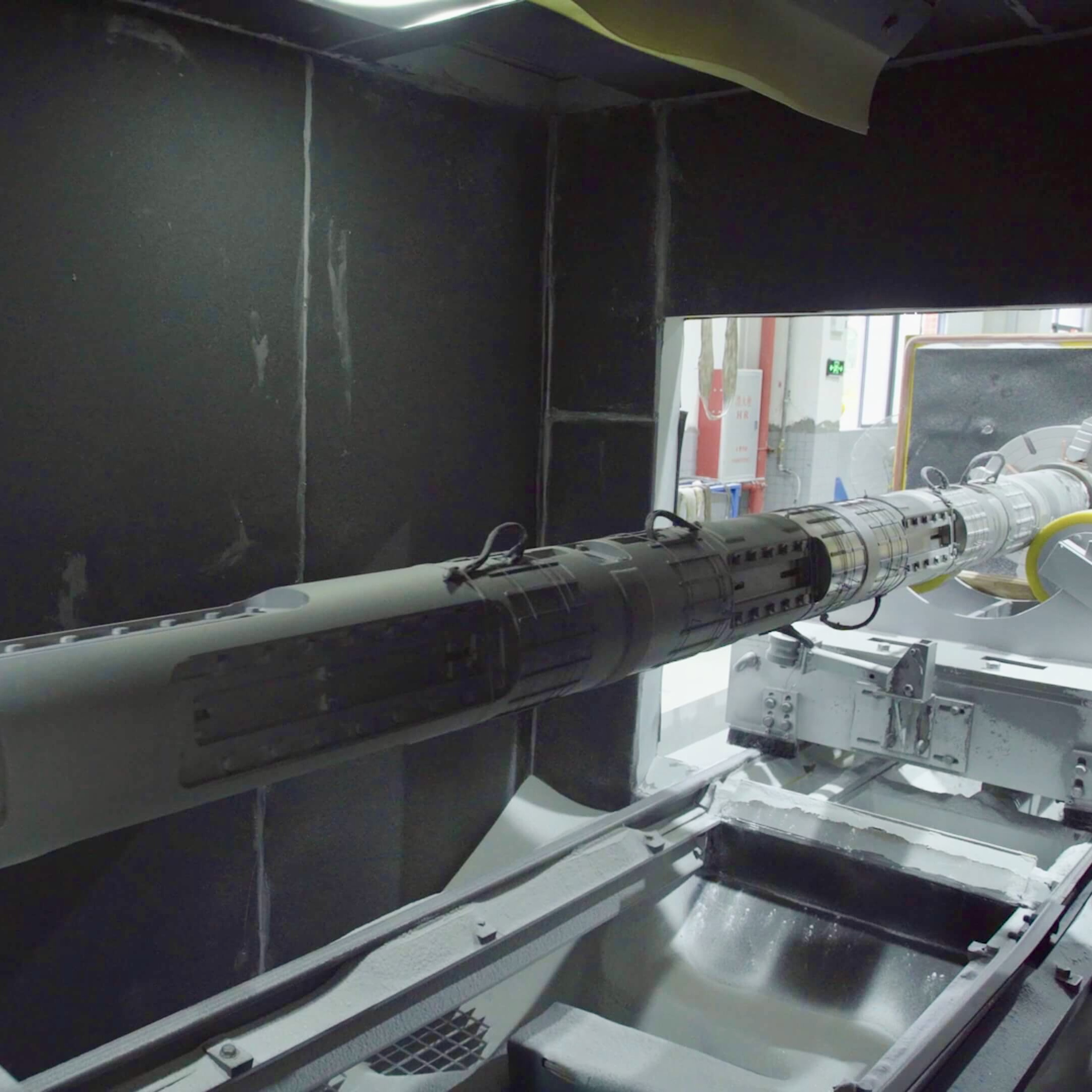

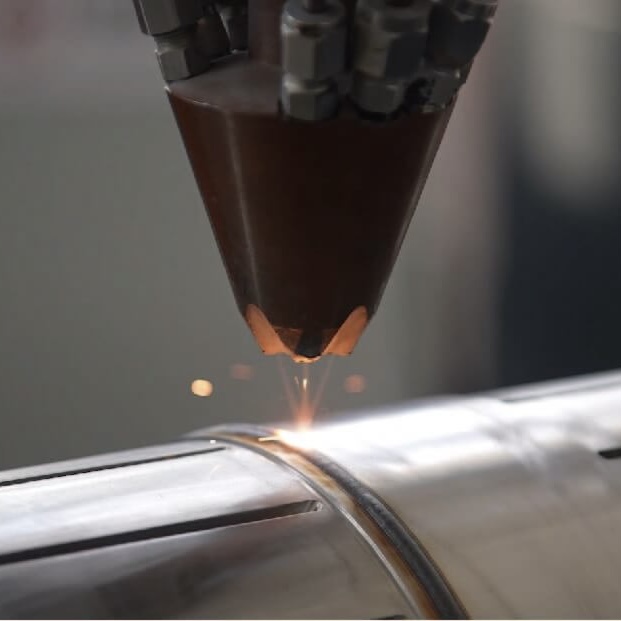

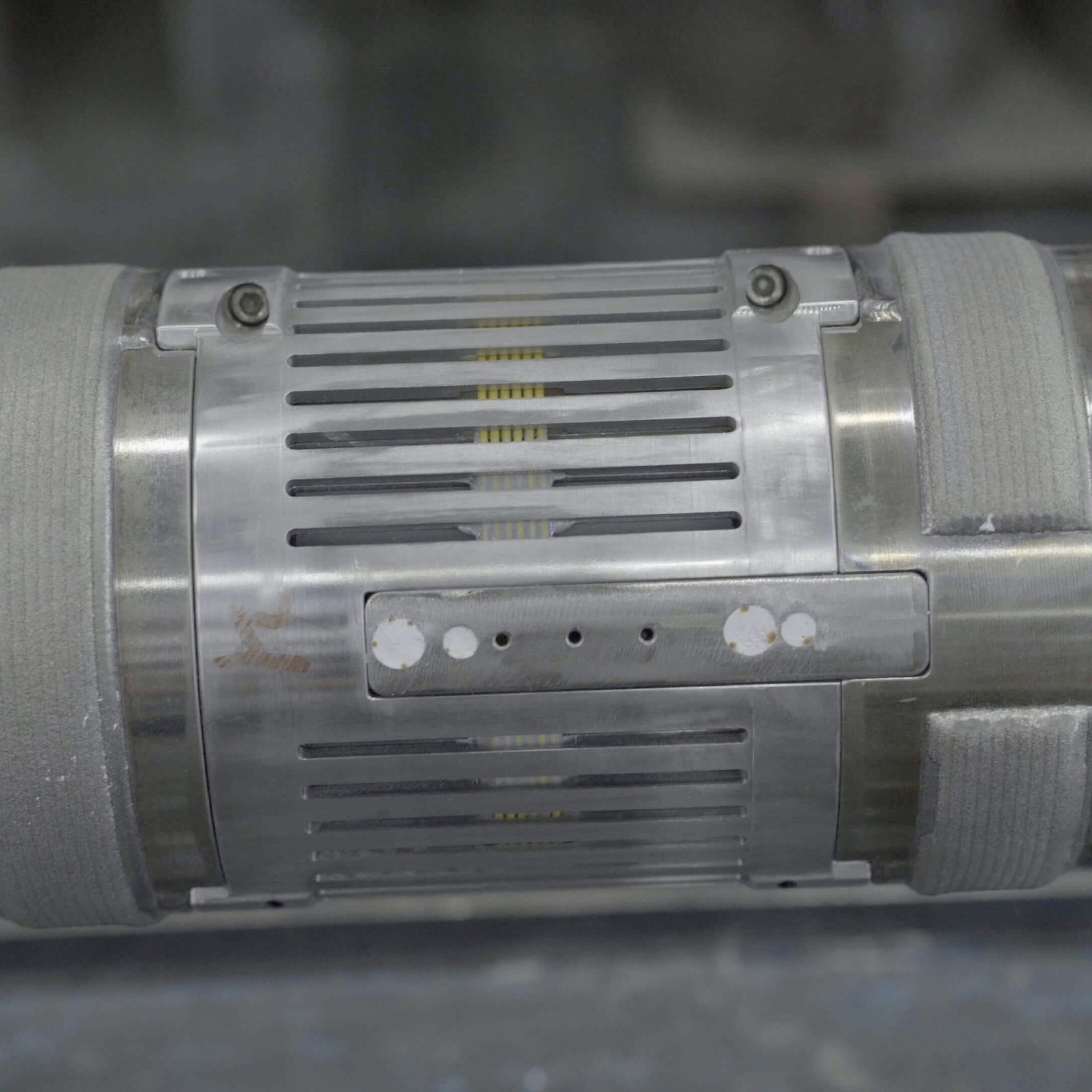

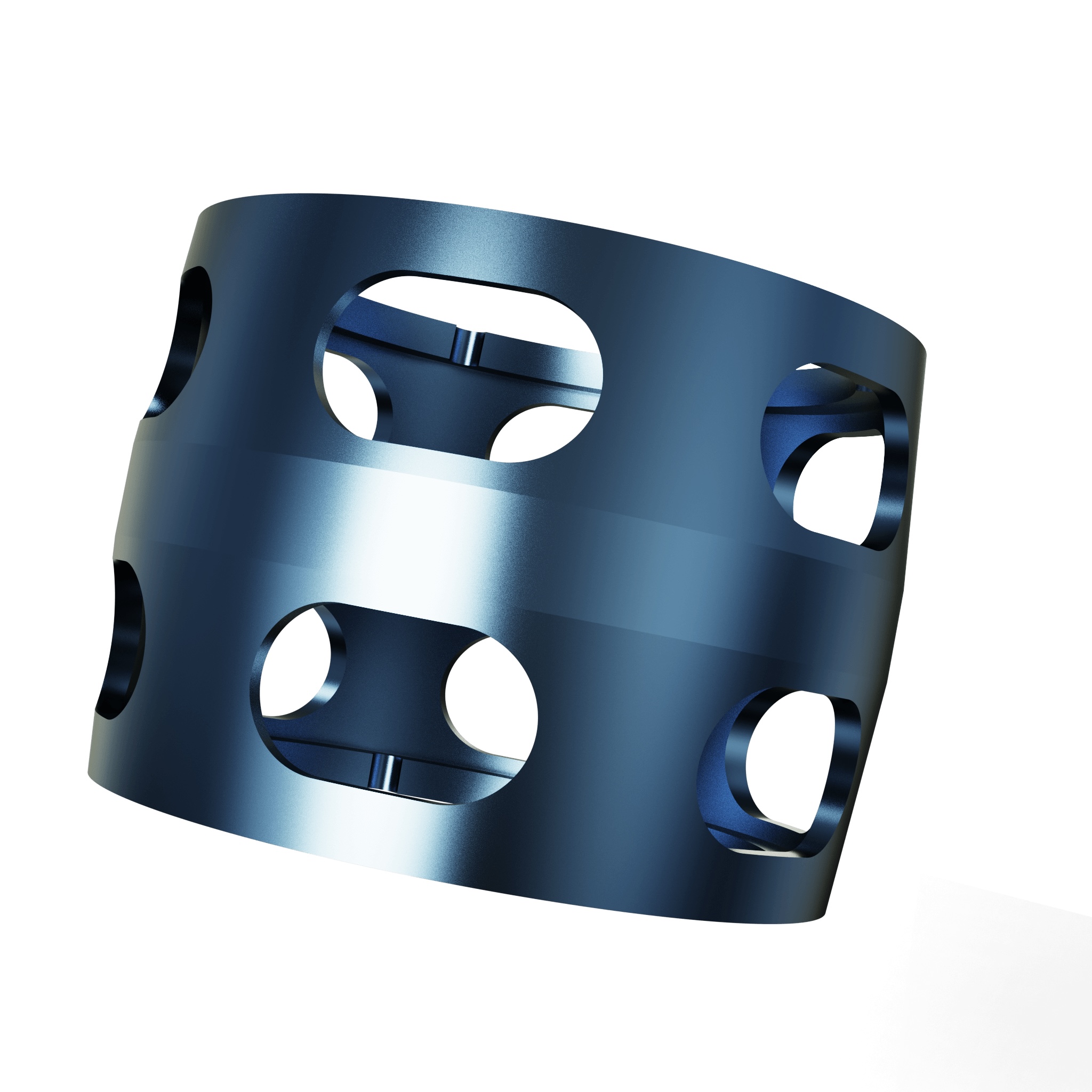

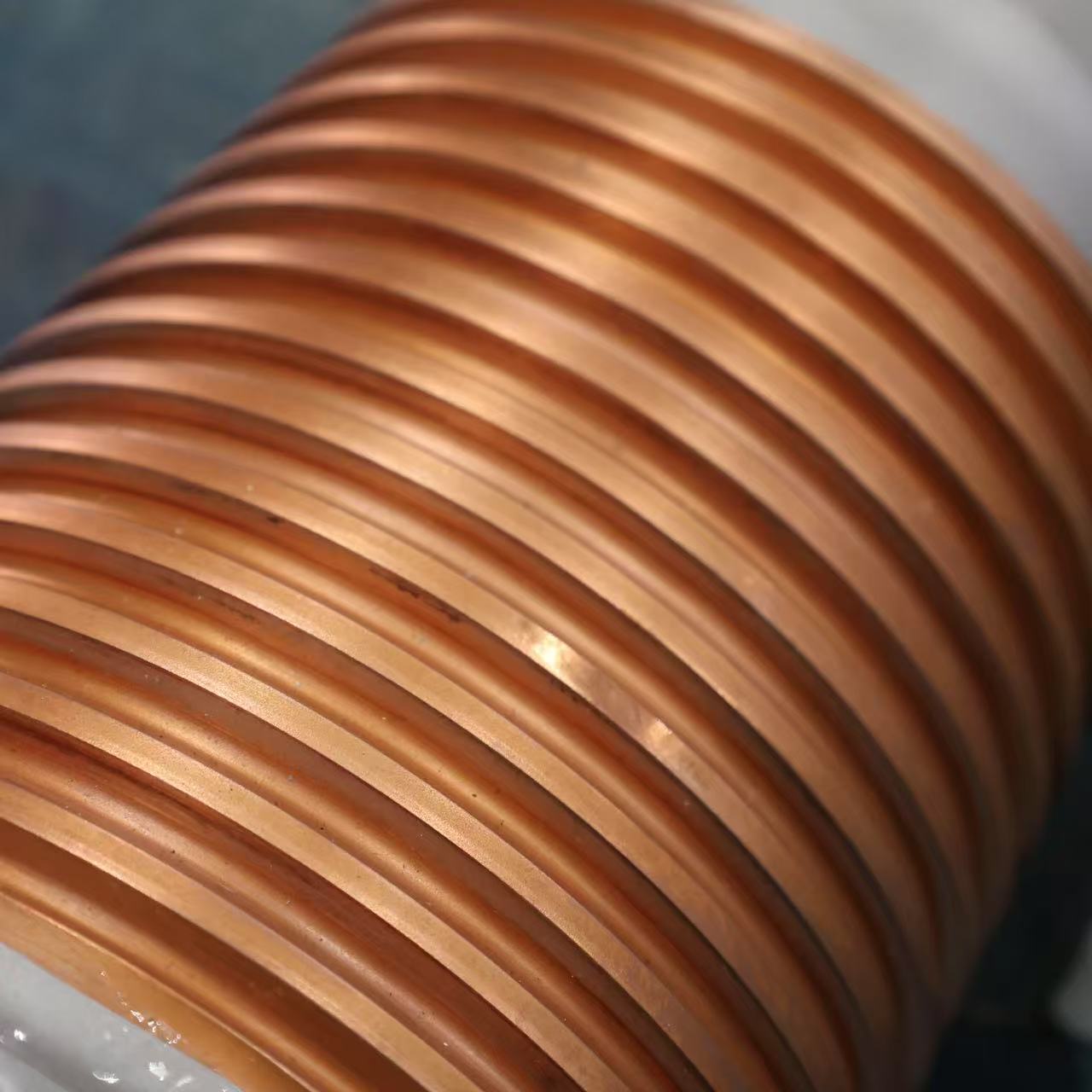

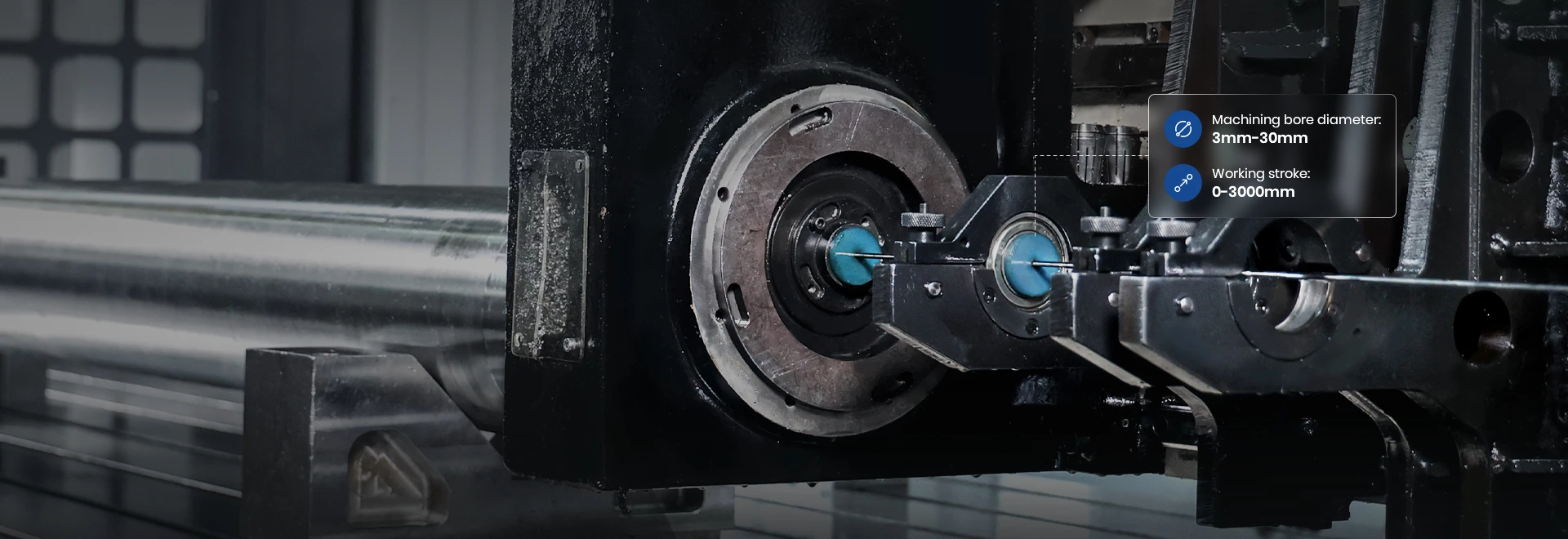

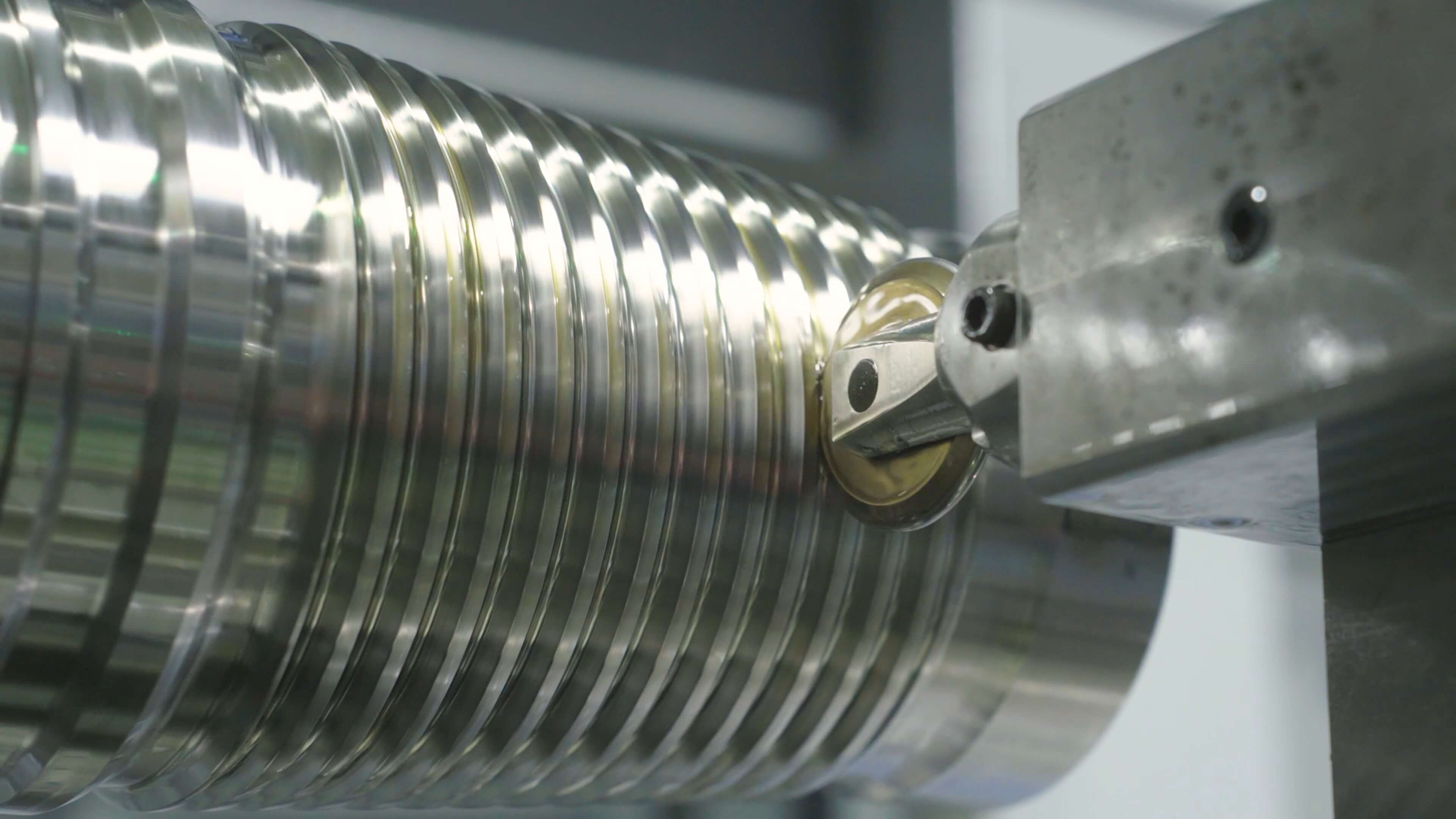

To improve the service life of the threads, the bottom of the threads is rolled using rolling wheels with a surface profile similar to the threads. This deforms and strengthens the bottom of the threads, improving their overall fatigue resistance.In view of different specifications of API threads and other special threads with unique structural parameters, such as tooth shape, taper, and pitch, the company researched and formulated a technological program with different rolling parameters. The company also designed a rolling device that successfully solved the thread rolling problem and controlled the amount of plastic deformation of the bottom arc within the drawing requirements. The surface roughness of the bottom arc after rolling reached Ra 0.1 μm, meeting the requirements of various special material threads.

Craft Case Gallery

Explore all gallery

Why us

Explore more

The Industrial Pilot Testing Service Capability

We achieve full-chain integration of prototype production, equipment assembly and intelligent maintenance to ensure full-cycle accurate delivery.

Scale Production

WELLTECH's modern production workshops, standardized process flow and efficient capacity layout enable scale production to meet customer needs with stable quality and batch delivery capability.

Shorten errors with technology and fulfill promises with precision

Let precision manufacturing understand you better - one click quotation, unlock efficient production password

Get a quote now