-

Home

- Technology

- Special arts and crafts

- Vacuum Plasma Nitriding

Industry challenges

Creating a new benchmark for precision manufacturing with exquisite

craftsmanship and innovative technology

Vacuum Plasma Nitriding

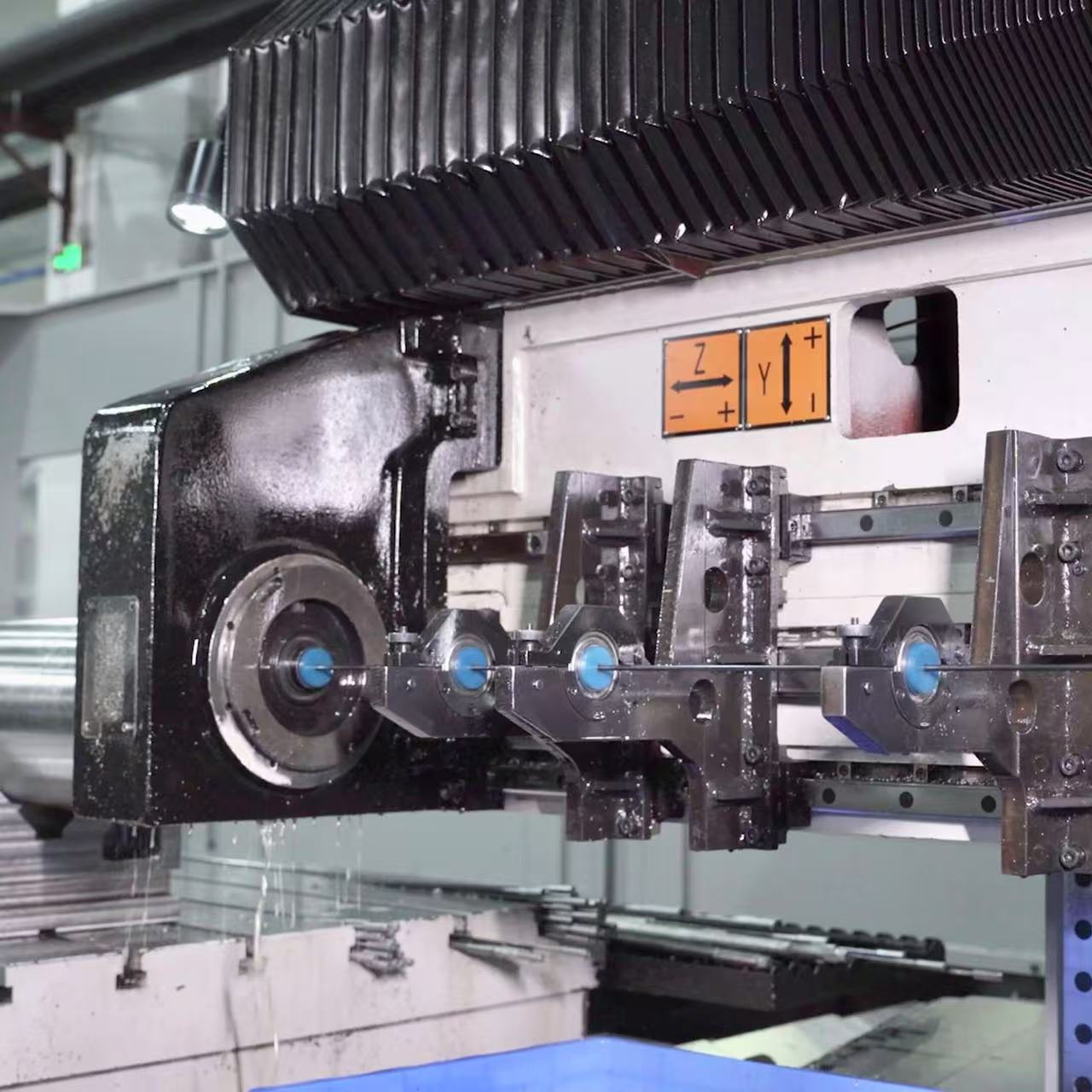

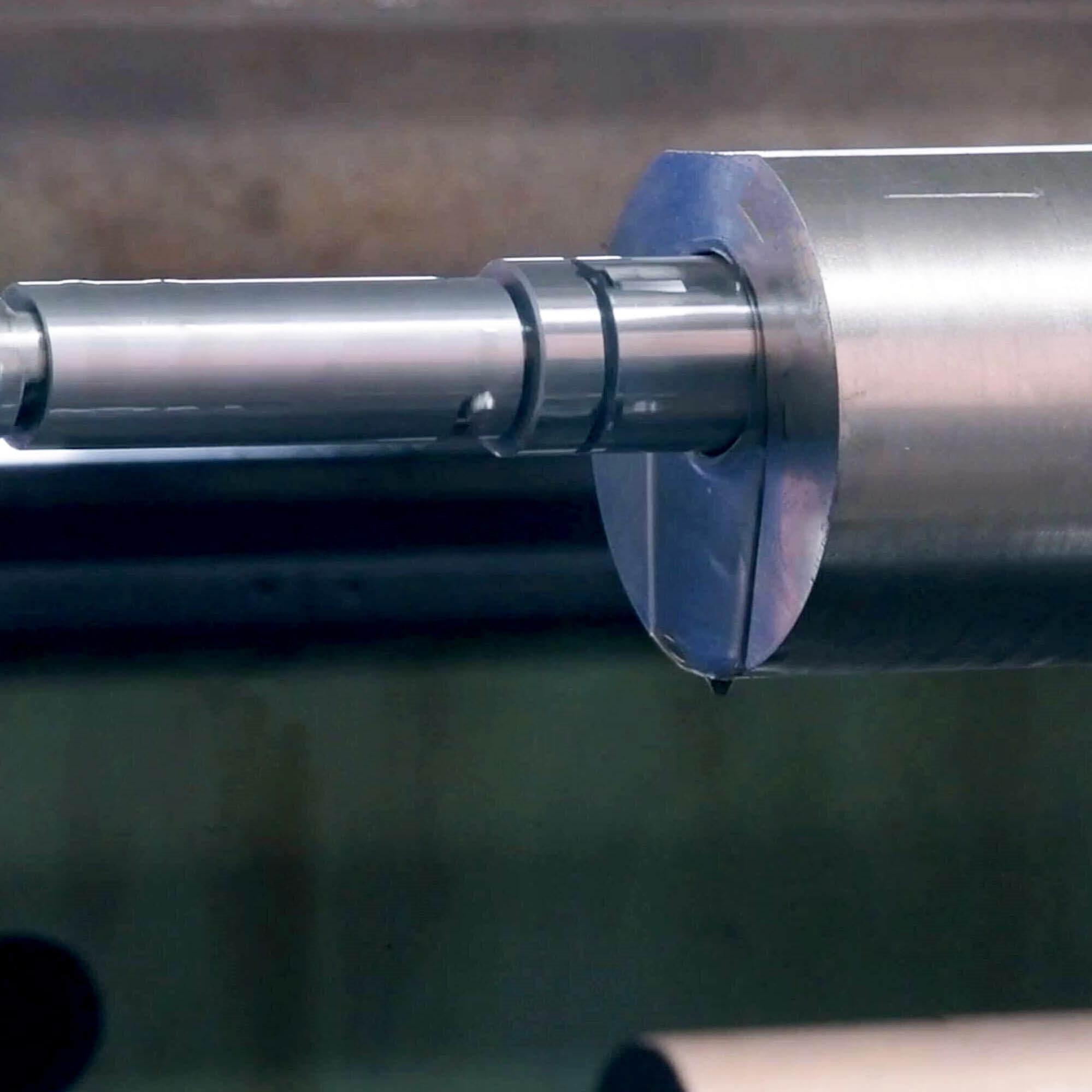

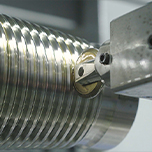

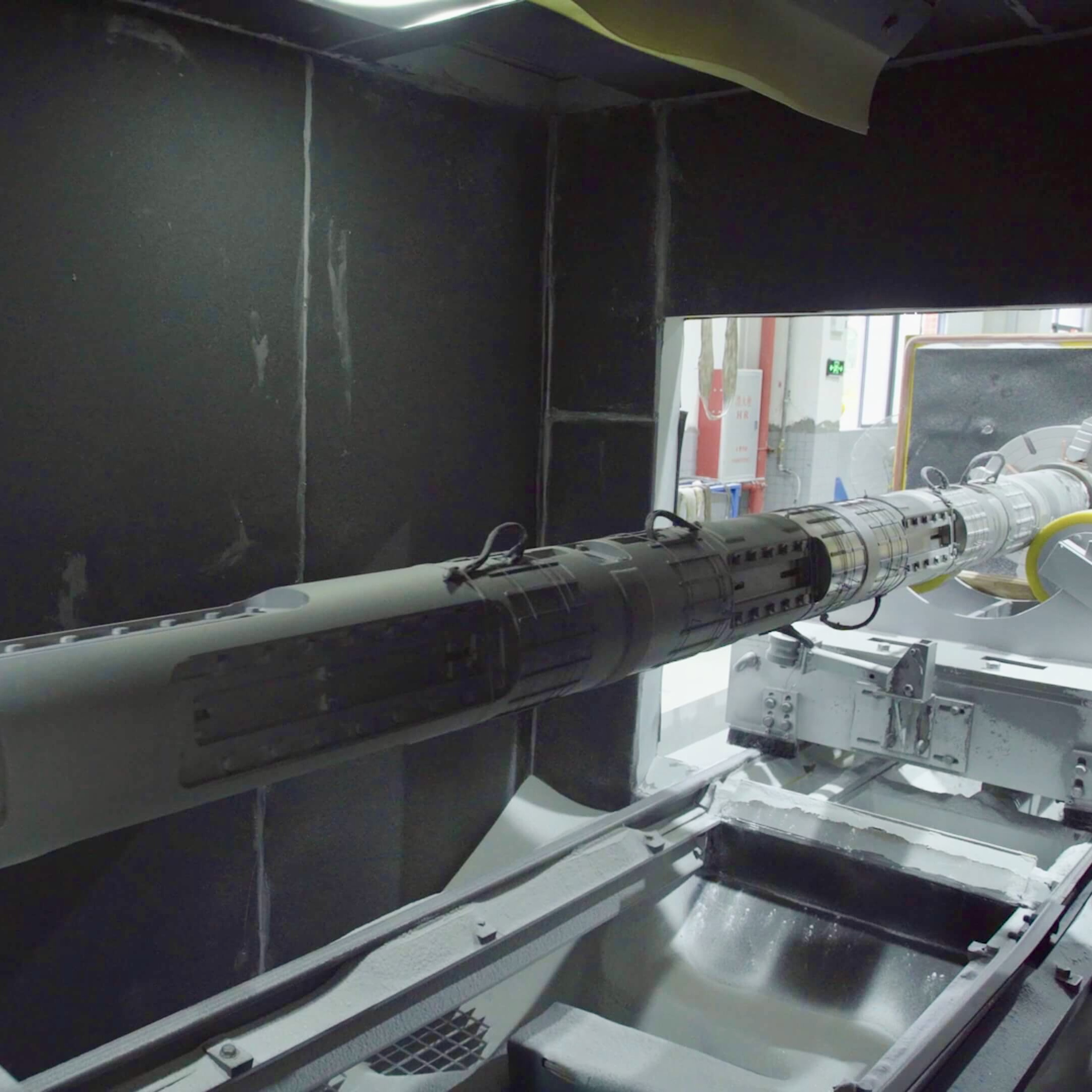

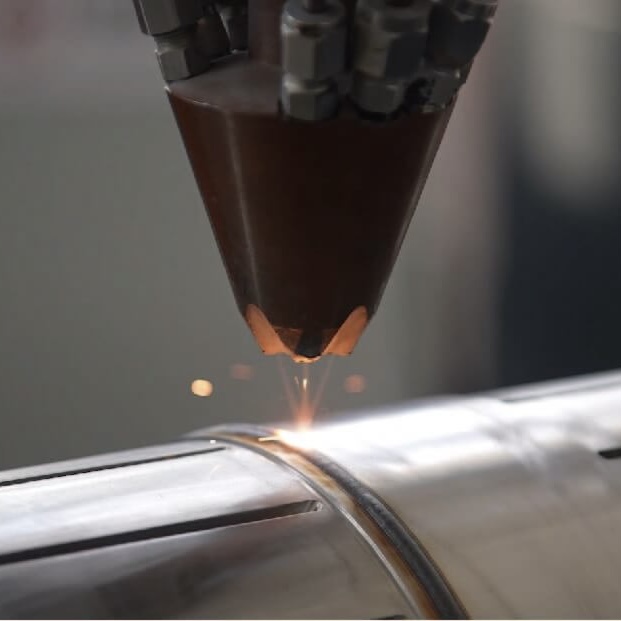

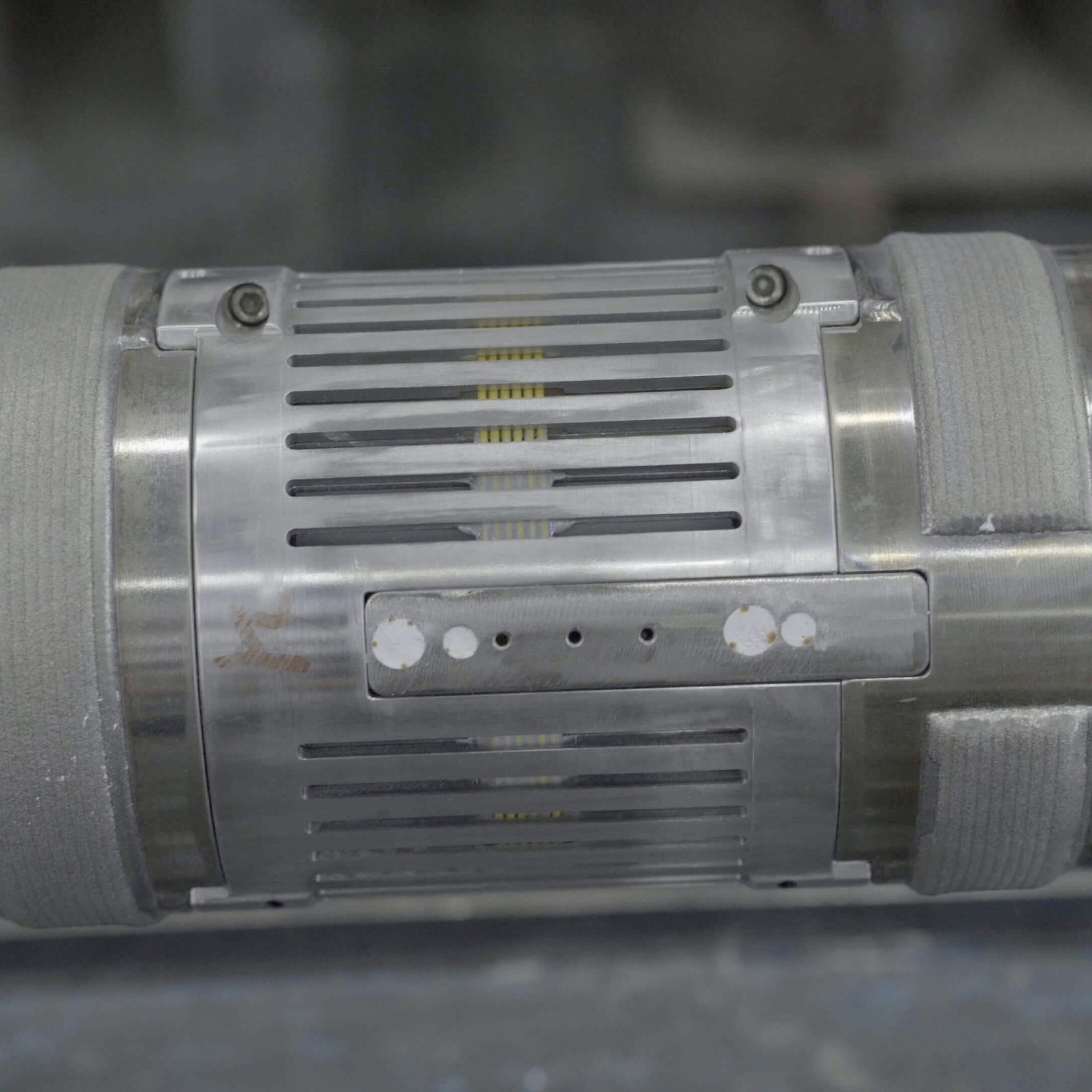

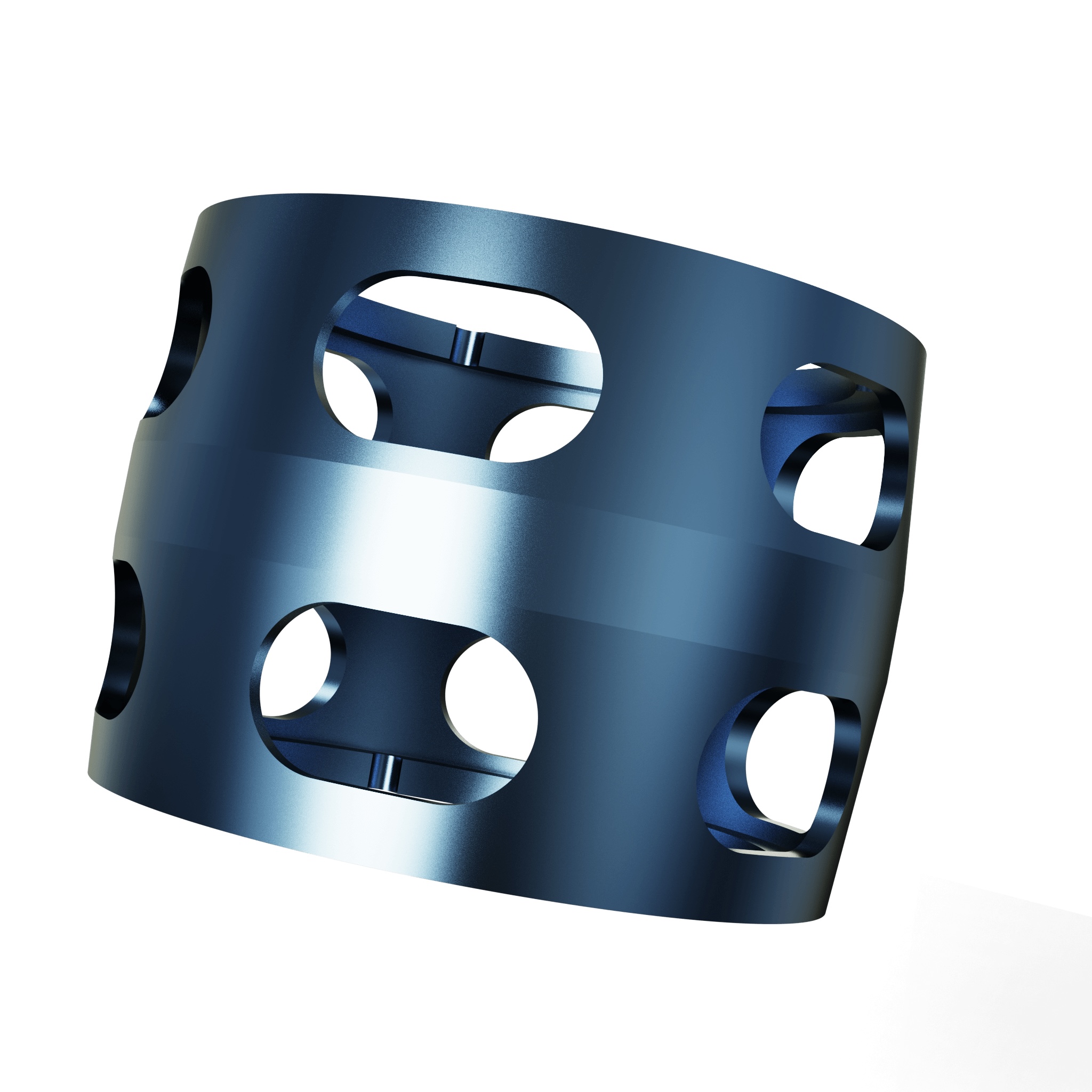

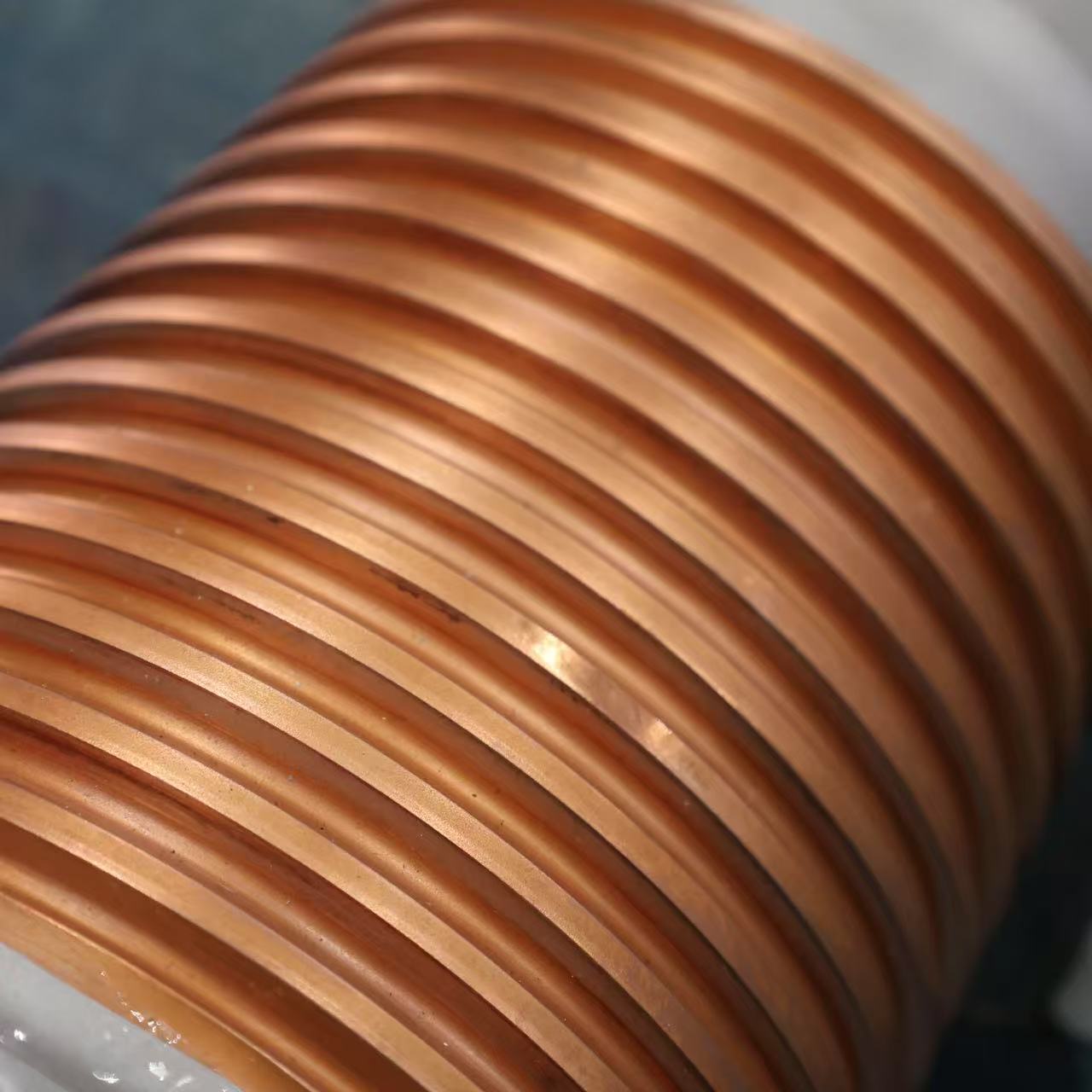

Vacuum plasma nitriding (VPN) is a kind of surface treatment technology that excites gases such as nitrogen and hydrogen into plasma through high-frequency electric current or microwave, and plasma generates nitride on the surface of parts and penetrates into the metal matrix to form a layer of wear-resistant nitrid layer, which is mainly used to enhance the hardness, wear resistance, corrosion resistance and fatigue strength of the metal surface. WELLTECH currently has vacuum plasma nitriding of nickel-based high-temperature alloy Inconel 718, with a surface hardness of parts above 60HRC and an effective thickness of the nitrided layer above 10 μm.

Craft Case Gallery

Explore all gallery

Why us

Explore more

The Industrial Pilot Testing Service Capability

We achieve full-chain integration of prototype production, equipment assembly and intelligent maintenance to ensure full-cycle accurate delivery.

Scale Production

WELLTECH's modern production workshops, standardized process flow and efficient capacity layout enable scale production to meet customer needs with stable quality and batch delivery capability.

Shorten errors with technology and fulfill promises with precision

Let precision manufacturing understand you better - one click quotation, unlock efficient production password

Get a quote now