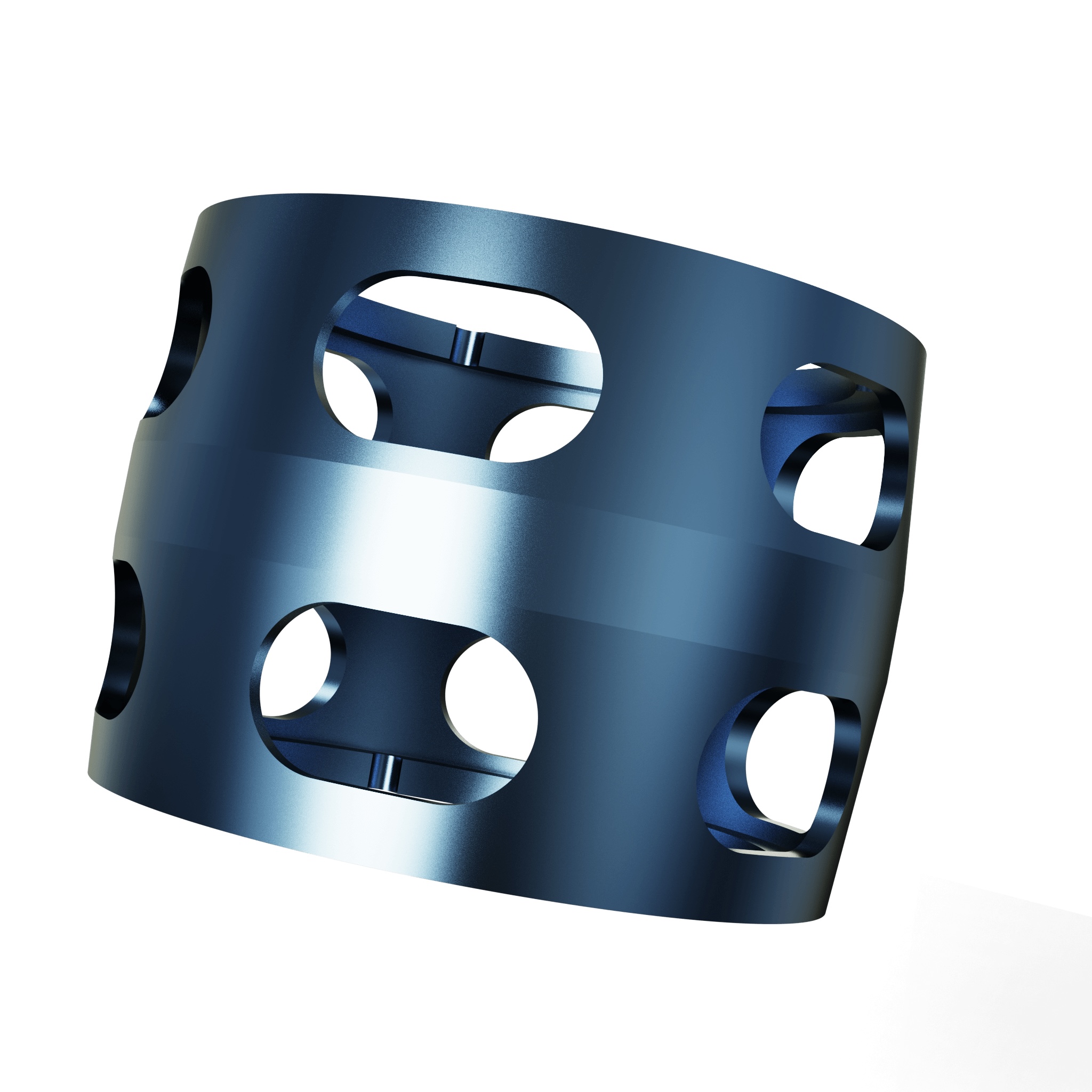

Electronically Controlled Common Rail Diesel Engine Common Rail Unit

Before 2007, domestic shipyards and supporting enterprises were unable to independently produce common rail units, relying entirely on imports from South Korea and Japan, which seriously restricted the localization process.

Core Challenges

Core Challenges 1

*Material Barriers: foreign common rail units used high-purity specialty steel, with no equivalent standardized material available domestically;

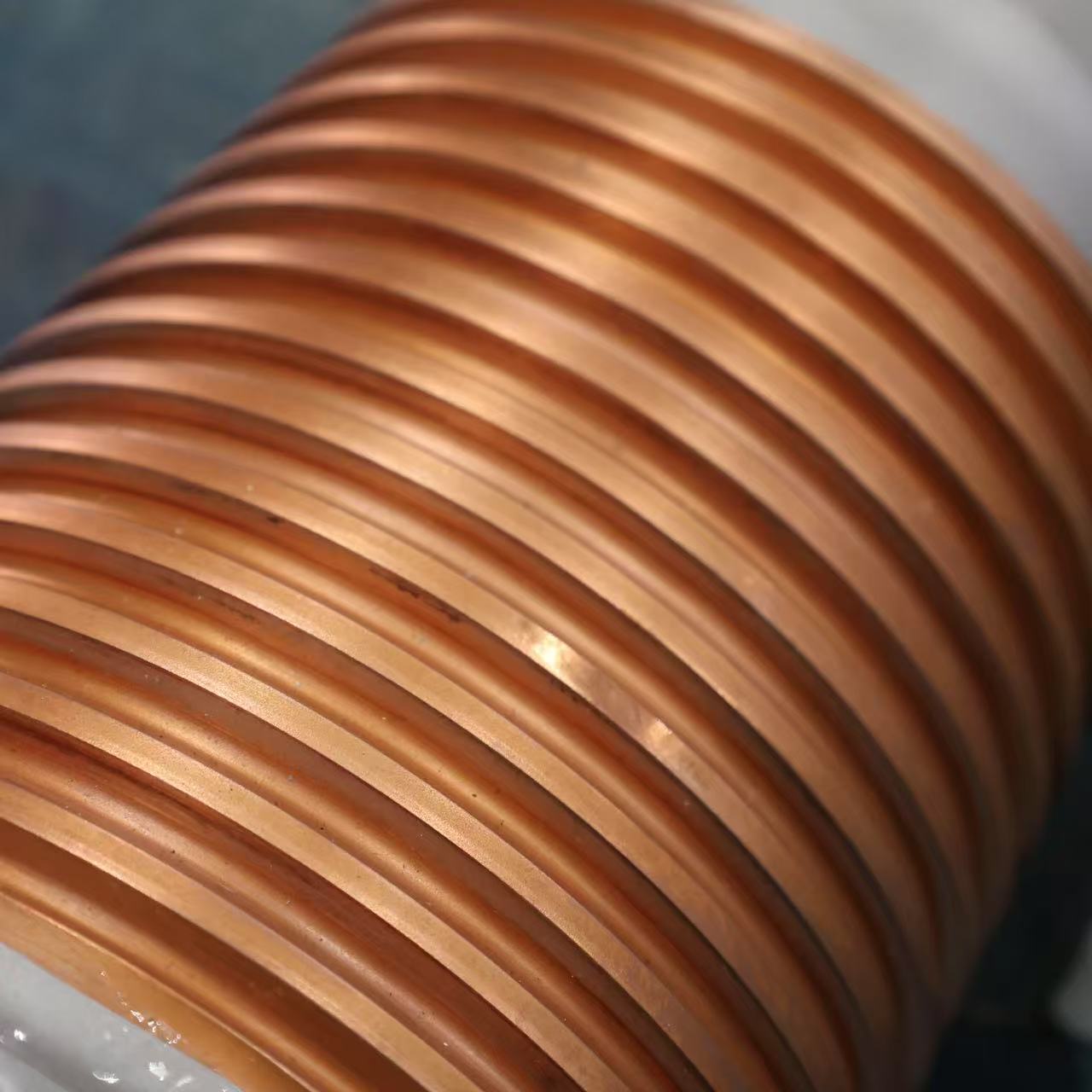

* Fuel pipe processing challenges:

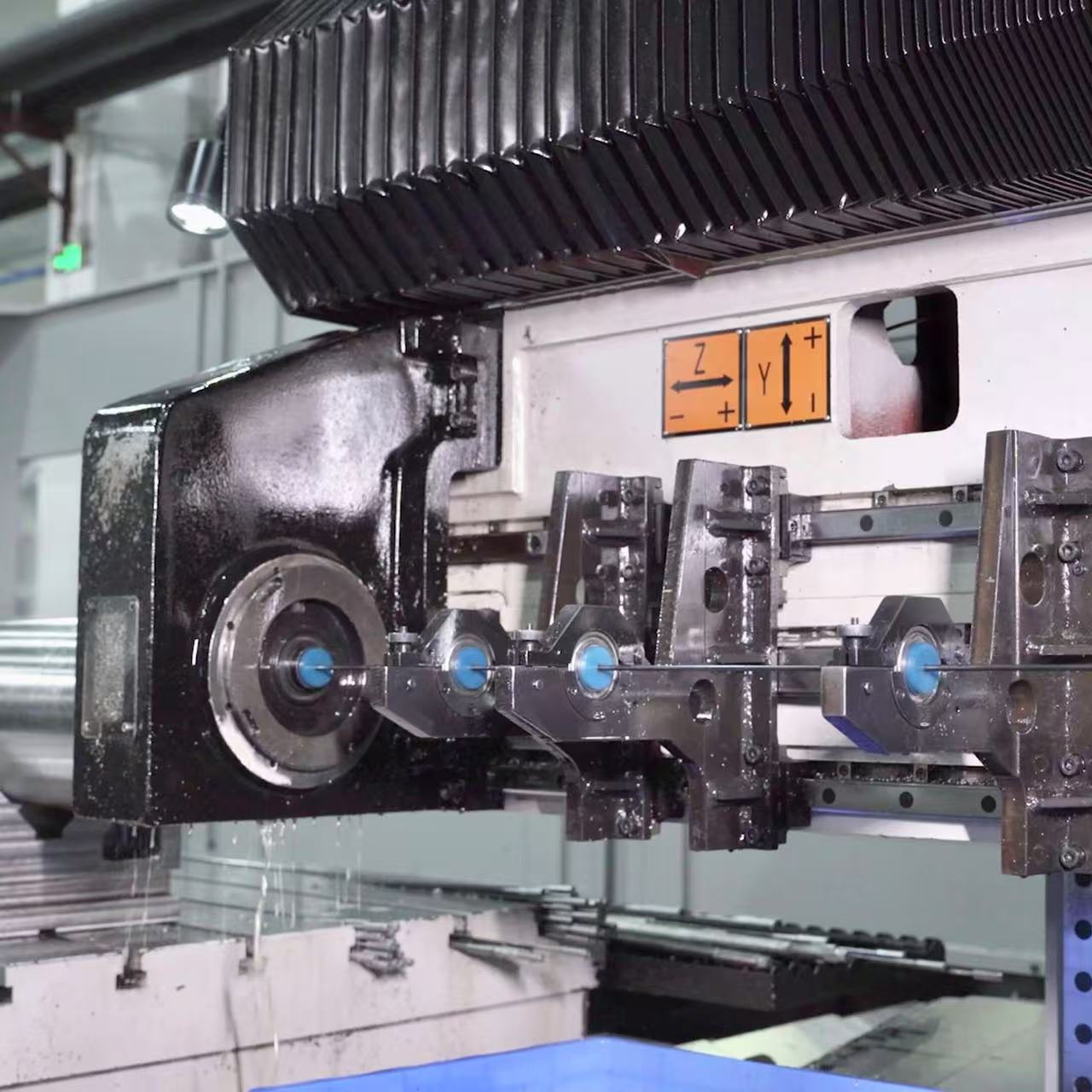

1.Peanut hole machining: Required surface finish of 3.2μm, hole spacing tolerance of ±0.3mm, length of 4000–12000mm, and axial hole twist relative to center hole ≤±15°;

2. Traditional process flaw: "Sequential drilling" caused precision loss due to tool deflection;

Core Challenges 2

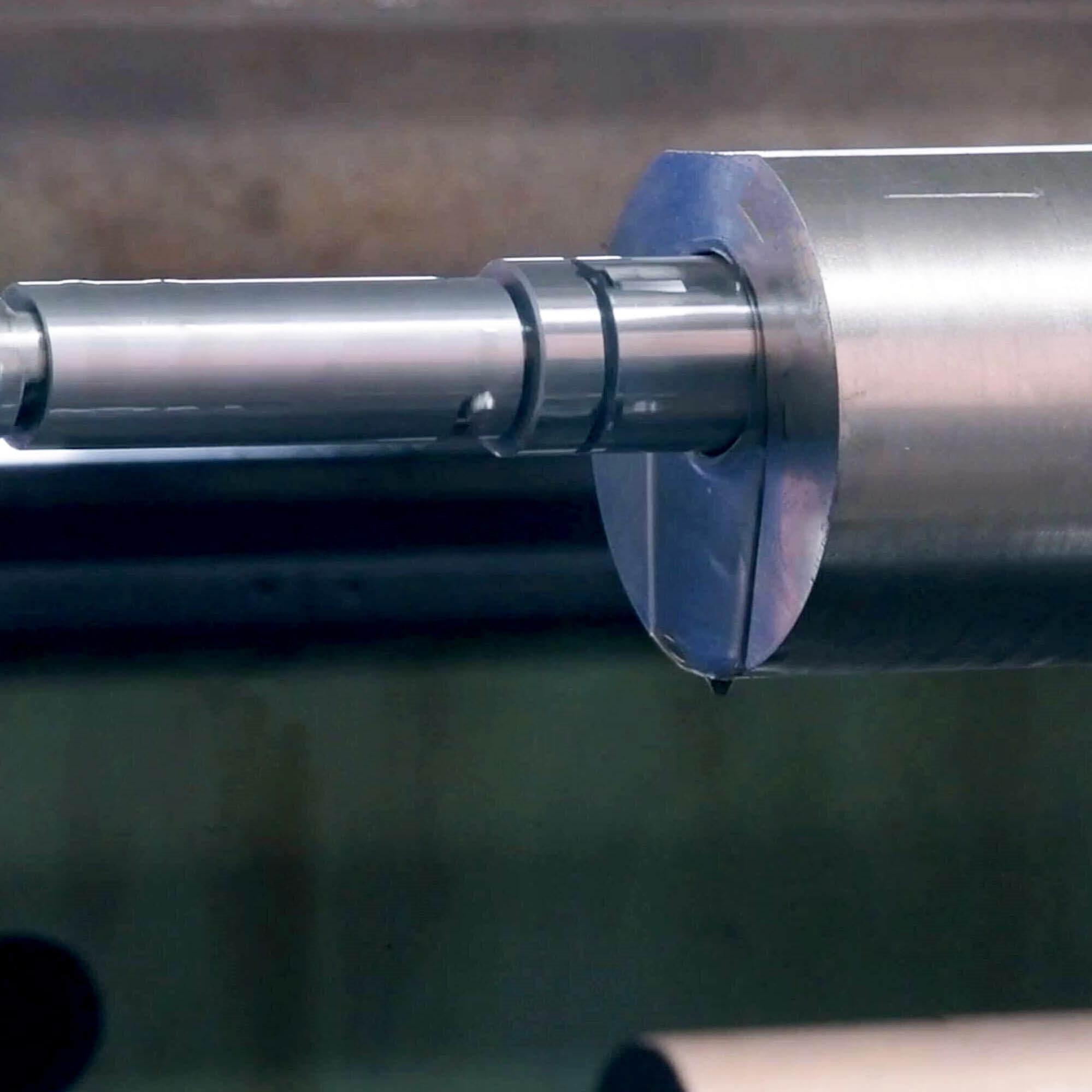

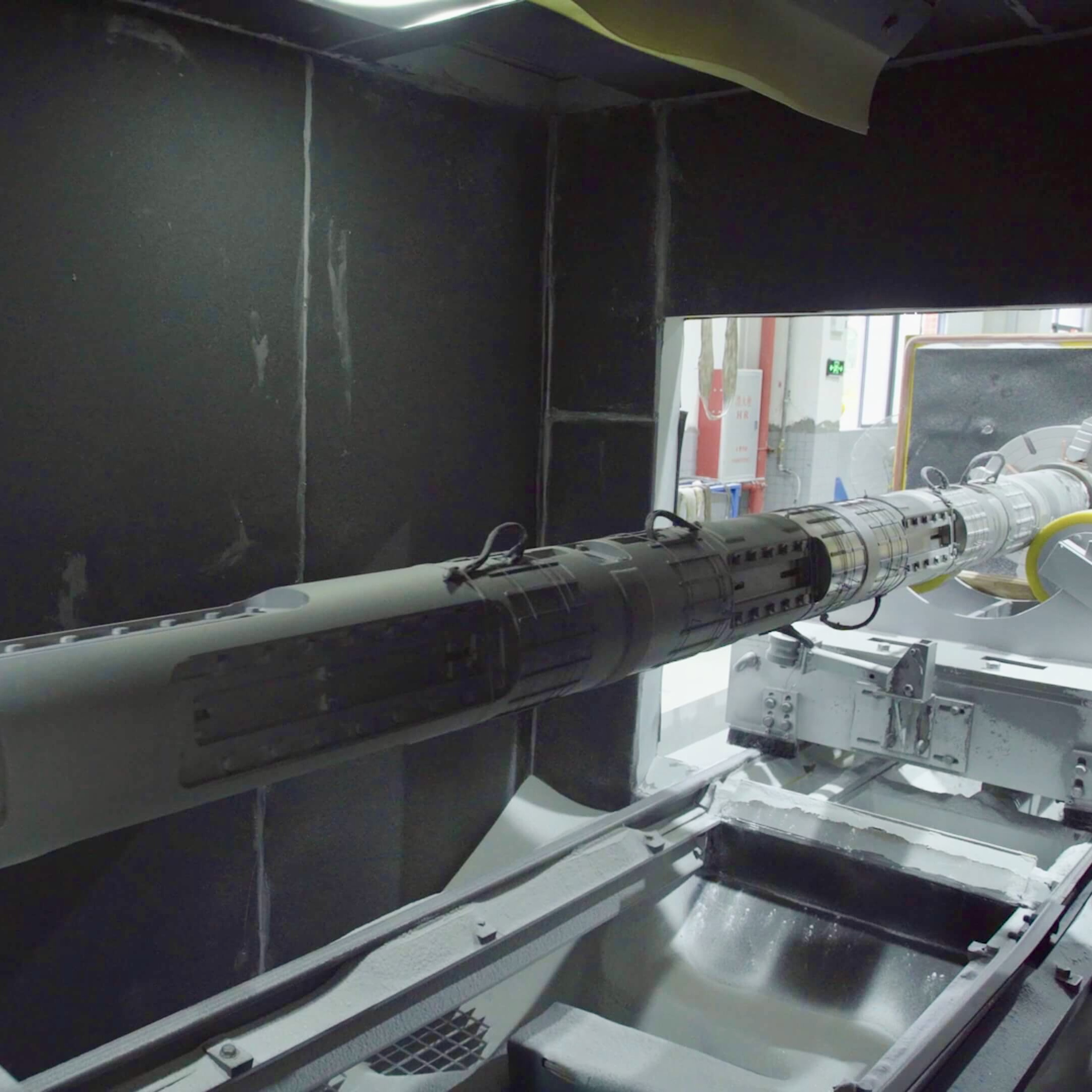

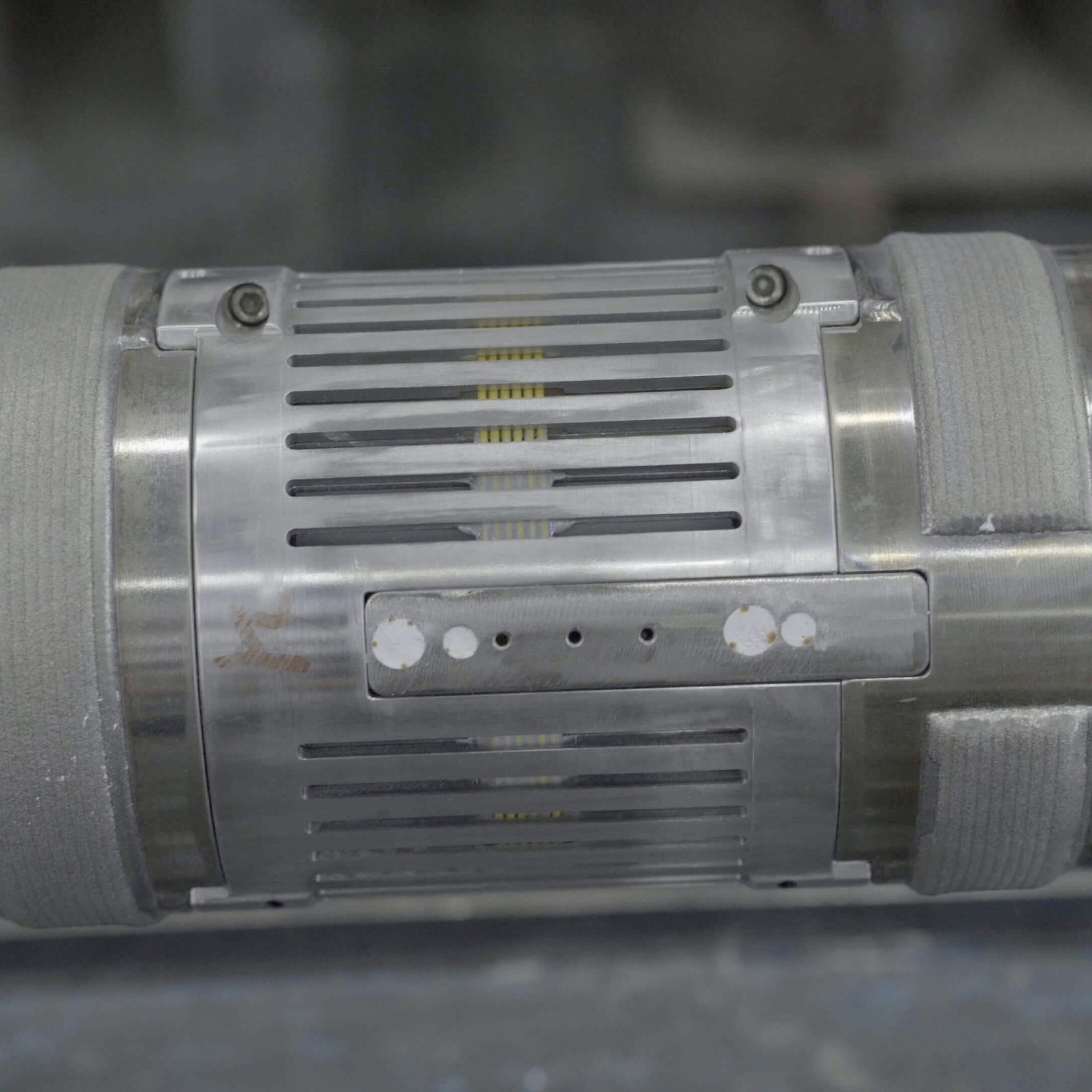

* Servo Pipe Machining Challenges: Precision boring and polishing of ultra-long slender pipes (12 meters);

* Low Valve Body Pass Rate: Foreign pressure control valves had only a 30% first-pass assembly success rate;

*Testing Dependency: Testing had to be conducted in Switzerland, resulting in long cycles, high costs, and production discontinuity.

Technological Breakthroughs

1. Material localization breakthrough: Develop domestic alternative materials through electroslag remelting, pre-furnace refining, forging and heat treatment and tempering process; performance and NDT indexes exceeded foreign standards and were certified by customers and classification societies.

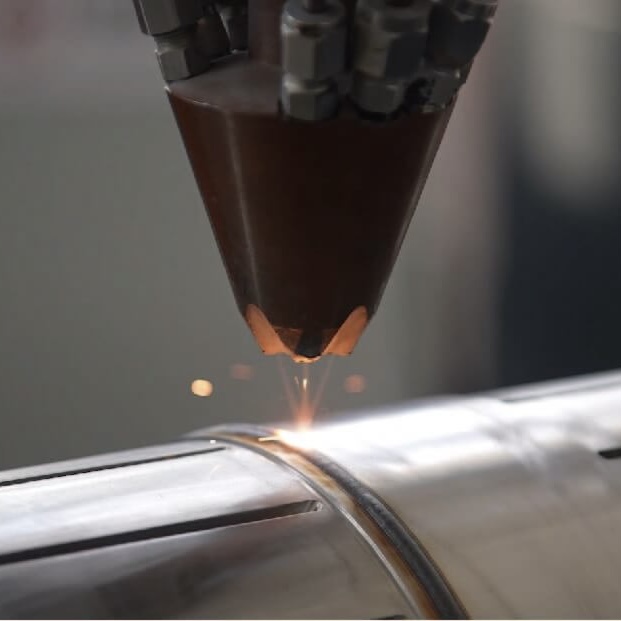

2. Fuel pipe process innovation and servo tube precision machining: developed a special guide device for peanut holes to solve the problem of letting the knife; optimize the process to ensure that the hole distance of ± 0.3mm, twist ≤ ± 15 °, and other core accuracy; developed an ultra-long servo tube bore polishing device to achieve high-precision polishing of the 12-meter fuel pipe.

3. High-efficiency assembly of the valve body: the use of special cutting tools, combined with 10 years of experience in diesel parts processing; the introduction of joint surface matching research process, an assembly qualification rate increased to more than 90%, significantly reducing rework costs.

Applications

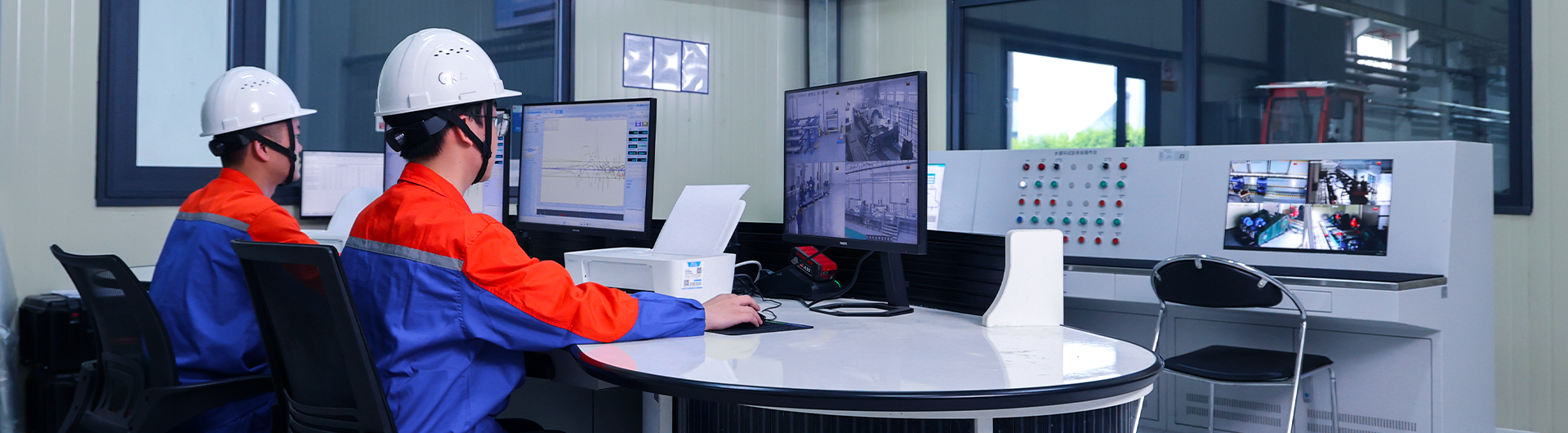

Developed 1500bar pressure test device and functional test equipment for common rail unit of electronically controlled common rail diesel engine, ending the dependence on foreign testing, breaking the foreign technical barriers, and filling the gaps in the domestic production of common rail unit of electronically controlled common rail diesel engine. Promote the design and manufacture of large marine electronically controlled common rail diesel engine upgrading, improve the domestic ship products loading rate, promote the development of the region and industry, greatly improve the competitiveness of China's shipbuilding industry in the world market, and contribute to the realization of China's shipbuilding power from a major shipbuilding country to a shipbuilding power.